-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

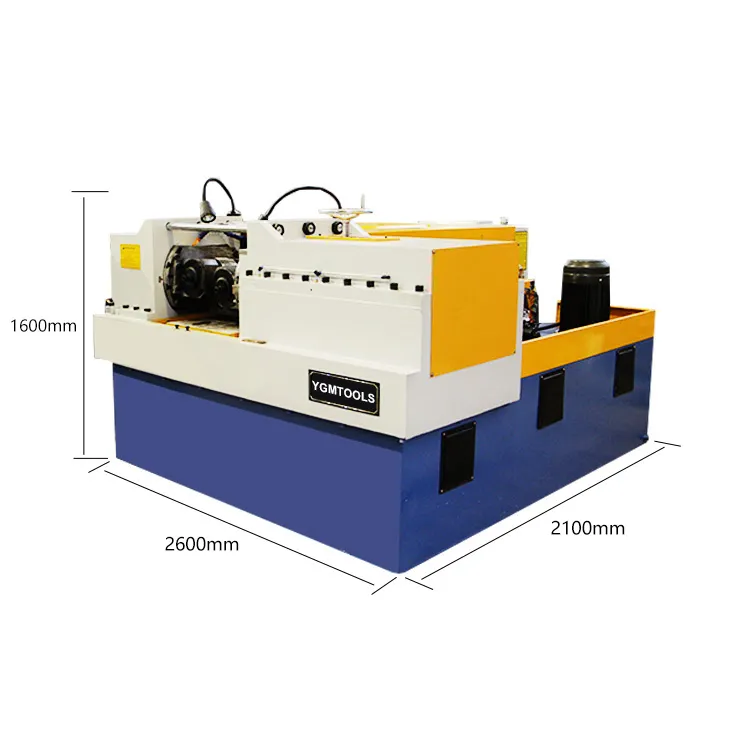

types of thread rolling machine products

Types of Thread Rolling Machine Products

Thread rolling is a manufacturing process used to create specific shapes and features on workpieces, particularly threads, by deforming the material rather than cutting it. This method boasts numerous advantages including increased strength, enhanced surface finish, and improved dimensional accuracy. In the realm of manufacturing and engineering, thread rolling machines come in various configurations tailored to different applications. Below, we explore the primary types of thread rolling machine products and their unique features.

1. Flat Die Thread Rolling Machines

Flat die thread rolling machines utilize two flat dies to exert force on the workpiece. These machines are particularly well-suited for producing external threads on cylindrical parts, such as bolts and screws. The process involves the rotation of the workpiece between the dies, which apply pressure in a specified direction to form the thread. Flat die machines are known for their simplicity, ease of operation, and ability to process a wide range of materials, including metals and plastics. They are commonly used in high-volume production settings due to their efficiency.

2. Planetary Thread Rolling Machines

Planetary thread rolling machines operate on a different principle by employing multiple rolling heads that move in a circular pattern around the workpiece. This design allows for the simultaneous processing of several threads, making it ideal for high-output production runs. The key advantage of the planetary system is the ability to create very precise threads and unique configurations, which would be challenging with other machine types. These machines are versatile and can be used for both external and internal threads, catering to an extensive variety of industries, including automotive and aerospace applications.

3. Screw Thread Rolling Machines

types of thread rolling machine products

Specifically designed for creating screw threads, these machines can generate threads with high precision and are critical in industries that require high-quality fasteners. Screw thread rolling machines can handle both continuous and batch production, and they often feature advanced control systems to ensure accuracy throughout the rolling process. The flexibility of these machines allows manufacturers to adapt to different specifications and standards, making them a valuable asset in thread manufacturing.

4. Rotary Thread Rolling Machines

Rotary thread rolling machines use a rotating motion to form threads, moving the dies around the workpiece while it remains stationary. This method is efficient for producing threads on long, continuous parts such as rods and bars. The design of rotary machines allows them to accommodate various sizes and lengths of materials, making them worth considering for companies that need flexibility in their production lines. These machines can create a range of thread forms, enhancing their applicability across different industrial sectors.

5. CNC Thread Rolling Machines

As industrial automation progresses, CNC (Computer Numerical Control) thread rolling machines have gained popularity. These machines integrate advanced technology to offer high precision and automation in the rolling process. CNC thread rolling machines can be programmed to perform various thread profiles and patterns, minimizing human error and maximizing efficiency. The ability to quickly change settings and designs allows manufacturers to respond rapidly to market demands, making CNC machines a preferred choice for modern manufacturing environments.

Conclusion

The world of thread rolling machines is diverse, offering a multitude of options tailored to specific thread production needs. From flat die machines for simple applications to advanced CNC machines capable of complex patterns, each type serves its purpose within the manufacturing process. As industries evolve and technology advances, the demand for reliable, efficient thread rolling machines will undoubtedly continue to grow, driving innovation and improvements in design and functionality. Understanding the characteristics and advantages of each type can help manufacturers choose the right machine to enhance their productivity and product quality in the competitive marketplace.