-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

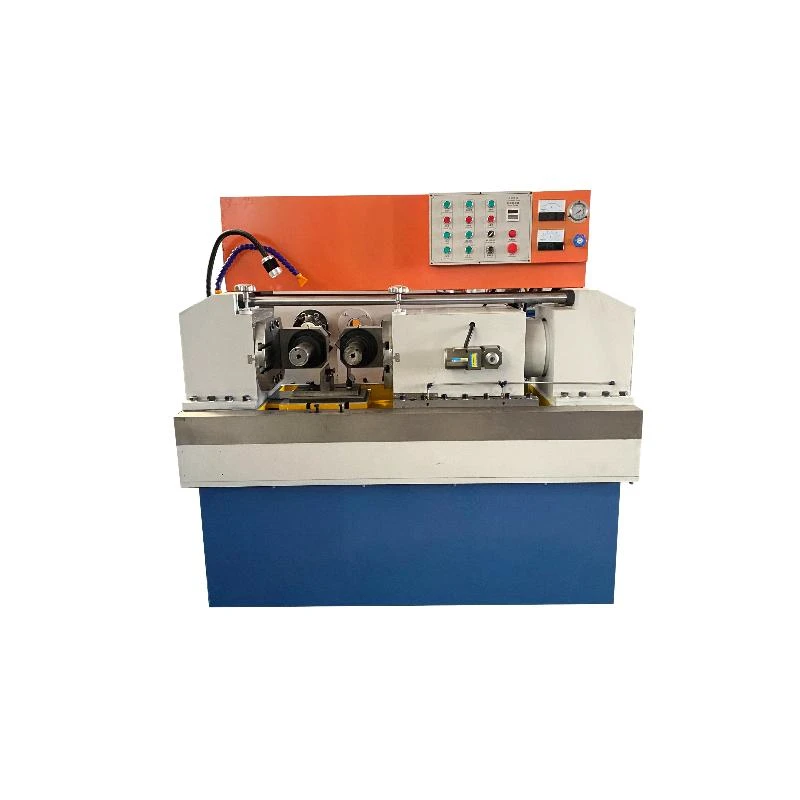

Different Varieties of Thread Rolling Machines and Their Applications

Understanding Types of Thread Rolling Machine Services

Thread rolling is a crucial process in the manufacturing sector, particularly for industries that require precision-engineered components such as automotive, aerospace, and machinery manufacturing. The ability to create robust and accurate threads enhances the performance and reliability of various products. As the demand for threaded components grows, the services associated with thread rolling machines have evolved significantly. This article delves into the different types of thread rolling machine services available, highlighting their importance and applications.

1. Standard Thread Rolling Services

Standard thread rolling services are perhaps the most common type of service offered. This process utilizes flat or cylindrical dies to create threads on a workpiece. The workpiece is pressed between the dies, causing the material to flow and take the shape of the die profile. This service is essential for producing threads with high accuracy and consistency. Industries that commonly use standard thread rolling include fastener manufacturing and general machining where uniform thread dimensions are crucial.

2. Custom Thread Rolling Services

Custom thread rolling services cater to specific requirements that standard services cannot fulfill. Many manufacturers need specialized threads for unique applications, which may require non-standard sizes, shapes, or designs. Custom services allow for the creation of threads that meet precise specifications, ensuring that components fit perfectly within their intended functions. For example, custom threads are essential in aerospace applications where every component must adhere to strict regulatory standards and performance criteria.

3. Multi-Start Thread Rolling Services

Multi-start thread rolling is an advanced service designed for creating threads with multiple starts on a single workpiece. This technique accelerates the production of threaded components, allowing for higher efficiency and reduced manufacturing times. Multi-start threads can be critical in applications requiring quick assembly or disassembly, such as in valve manufacturing or in machinery where rapid adjustments are needed. Providers of this service often work closely with clients to ensure that the unique geometry of multi-start threads meets design requirements.

types of thread rolling machine service

4. Tube and Rod Thread Rolling Services

Thread rolling is not limited to flat surface applications; it can also be applied to tubes and rods. Tube and rod thread rolling services are specialized because they require machinery capable of handling the circular geometry and maintaining the integrity of the material during the threading process. This type of service is vital in industries like oil and gas, where threaded connections on rods and tubes must withstand extreme pressures and environments.

5. Thread Rolling Machine Maintenance Services

Alongside the production of threaded components, the maintenance of thread rolling machines is a crucial offering. Regular maintenance services ensure that machines operate efficiently, minimizing downtime due to equipment failure. These services can include routine checks, alignment adjustments, and parts replacements. By investing in maintenance, manufacturers can extend the lifespan of their machines, ensure the quality of their products, and optimize production schedules.

6. Thread Inspection and Quality Assurance Services

Quality assurance is an essential part of the thread rolling process. Inspection services are often integrated to ensure that threaded components meet specified dimensions and tolerances. This service may include the use of advanced measurement tools and techniques, such as Coordinate Measuring Machines (CMM) and laser scanning. Ensuring the quality of threaded parts is indispensable in industries where safety and performance are paramount.

Conclusion

In conclusion, the variety of thread rolling machine services available today reflects the diverse needs of modern manufacturing. From standard and custom thread rolling services to specialized offerings like multi-start threads, tube and rod threading, and comprehensive maintenance and inspection services, the thread rolling sector is pivotal for many industries. As technology advances and demands grow, these services will continue to evolve, offering even greater efficiency and precision in production processes. Understanding these services is vital for manufacturers aiming to remain competitive and deliver high-quality products that meet the exacting standards of their respective industries.