-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 06, 2025 12:04

Back to list

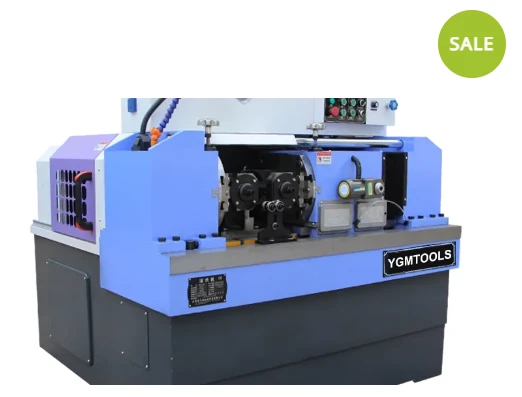

types of thread rolling machine supplier

Thread rolling machines have become a backbone for industrial purposes, particularly in sectors requiring high precision and efficiency. Selecting a thread rolling machine supplier, however, often presents a conundrum due to the varied nature of the machinery and its applications. Exploring the different types of thread rolling machines illuminates the pathway towards making an informed decision.

When choosing a supplier, consider their expertise and reputation. An expert supplier will not only boast a wide range of machines but also provide insights into the best applications for each. A reputable supplier will have proven experience demonstrated through client testimonials, case studies, or long-term partnerships in the industry. Such indicators reflect a deep understanding of thread rolling technology, ensuring that your acquisition will meet current production needs while offering the potential for future scalability. Moreover, the supplier's ability and readiness to provide maintenance and after-sales support is crucial. Thread rolling machines, with their intricate mechanics, require regular upkeep to maintain peak performance. Renowned suppliers offer comprehensive support, ranging from routine maintenance checks to the rapid provision of spare parts, thus minimizing downtime and ensuring seamless operation. Relational dynamics also matter; partnerships built on trust can drive long-term success. Suppliers with transparent business practices, flexible policy terms, and robust communication channels can significantly ease the procurement process, making them invaluable allies in your operational endeavors. Security in your investment also involves considering technological innovation. Suppliers who lead in industry advancements, such as digital integration and enhanced automation in thread rolling machinery, signify a forward-thinking approach requisite for staying competitive. Machines embedded with IoT technology, for example, facilitate real-time monitoring, predictive maintenance, and overall equipment efficiency analysis — features that should not be overlooked in your decision-making process. In conclusion, opting for the best thread rolling machine supplier is not a mere transactional process but a strategic partnership. An optimal supplier will offer a holistic package involving diverse machine types tailored to your specific manufacturing needs, backed by credible experience, authority in technology, and unwavering trustworthiness in all facets of the business relationship. A focus on finding such partners ensures not only quality production but also paves the way for continuous growth and innovation.

When choosing a supplier, consider their expertise and reputation. An expert supplier will not only boast a wide range of machines but also provide insights into the best applications for each. A reputable supplier will have proven experience demonstrated through client testimonials, case studies, or long-term partnerships in the industry. Such indicators reflect a deep understanding of thread rolling technology, ensuring that your acquisition will meet current production needs while offering the potential for future scalability. Moreover, the supplier's ability and readiness to provide maintenance and after-sales support is crucial. Thread rolling machines, with their intricate mechanics, require regular upkeep to maintain peak performance. Renowned suppliers offer comprehensive support, ranging from routine maintenance checks to the rapid provision of spare parts, thus minimizing downtime and ensuring seamless operation. Relational dynamics also matter; partnerships built on trust can drive long-term success. Suppliers with transparent business practices, flexible policy terms, and robust communication channels can significantly ease the procurement process, making them invaluable allies in your operational endeavors. Security in your investment also involves considering technological innovation. Suppliers who lead in industry advancements, such as digital integration and enhanced automation in thread rolling machinery, signify a forward-thinking approach requisite for staying competitive. Machines embedded with IoT technology, for example, facilitate real-time monitoring, predictive maintenance, and overall equipment efficiency analysis — features that should not be overlooked in your decision-making process. In conclusion, opting for the best thread rolling machine supplier is not a mere transactional process but a strategic partnership. An optimal supplier will offer a holistic package involving diverse machine types tailored to your specific manufacturing needs, backed by credible experience, authority in technology, and unwavering trustworthiness in all facets of the business relationship. A focus on finding such partners ensures not only quality production but also paves the way for continuous growth and innovation.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025