-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Different Methods and Techniques for Thread Rolling Processes and Applications

Understanding the Different Types of Thread Rolling

Thread rolling is a popular manufacturing process utilized to create threads on fasteners and various components, enhancing their mechanical properties while maintaining dimensional accuracy. This cold-forming technique has gained significant traction in various industries due to its efficiency and cost-effectiveness. In this article, we will explore the different types of thread rolling processes and their applications.

1. Flat Die Thread Rolling

Flat die thread rolling is one of the most common forms of thread rolling, where the material is compressed between two flat dies to form a thread. The component is held in place and rotated while the dies apply pressure, causing the material to flow and shape into a thread profile. This method is highly efficient for producing a large volume of threaded parts with consistent dimensions. It is primarily used for bolts, screws, and other types of fasteners that require high-precision threads.

2. Circular Die Thread Rolling

Circular die thread rolling, or cylindrical thread rolling, utilizes two circular dies that rotate in opposite directions. As the workpiece is fed between these dies, it is shaped into the desired thread profile. This method is particularly favorable for producing longer threaded components with a continuous thread. Circular die thread rolling is often employed in the automotive and aerospace industries, where reliable and robust threading is crucial.

types of thread rolling quotes

Roller thread rolling is a more specialized method where a cylindrical rolling tool is used to create threads. The roller is designed to match the specific shape of the desired thread and can produce complex profiles with high accuracy. This technique is often used in applications that require unique thread shapes or when dealing with materials that are challenging to thread using traditional methods. Roller thread rolling is particularly advantageous for creating threads in harder materials, as the process does not generate significant heat, preventing warping or damage.

4. Ram Thread Rolling

In ram thread rolling, the punch-and-die system moves horizontally which compresses the workpiece to form the thread. This method is less common but offers the ability to produce specific thread configurations that other methods may not achieve. It is primarily used for specialized applications where intricate detailing in threads is required.

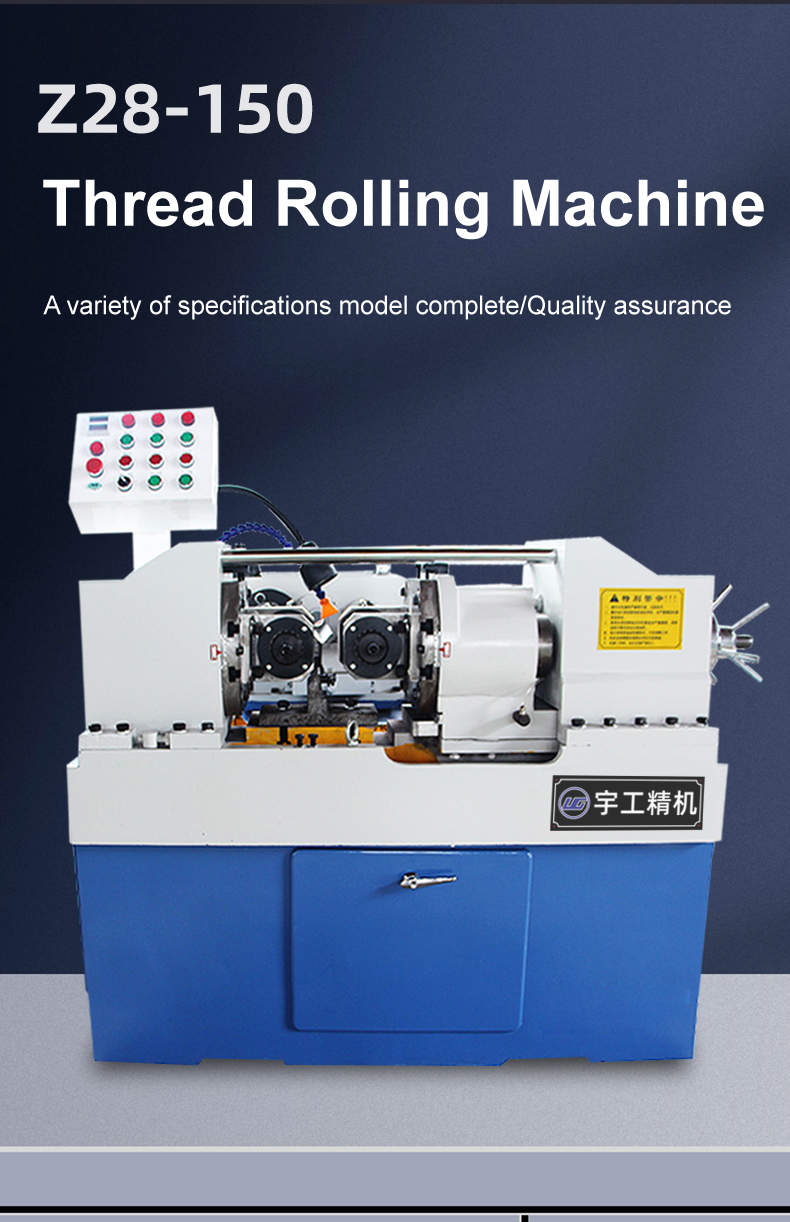

5. Thread Rolling Machines

Investing in thread rolling machines is essential for manufacturers seeking to enhance production efficiency. These machines can be automated for high-volume output while ensuring precision in thread formation. Advanced models often come with computer numerically controlled (CNC) capabilities, allowing for easy adjustments and programming for varied thread sizes and types.

Conclusion

Thread rolling is a versatile process with various methods tailored for different applications. Each type has its own advantages, making it suitable for specific threading requirements. By understanding the distinctions among flat die, circular die, roller, and ram thread rolling, manufacturers can choose the appropriate method for their production needs. As technology advances, the thread rolling industry continues to evolve, offering even more efficient and effective solutions for creating high-quality threads in diverse materials.