-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

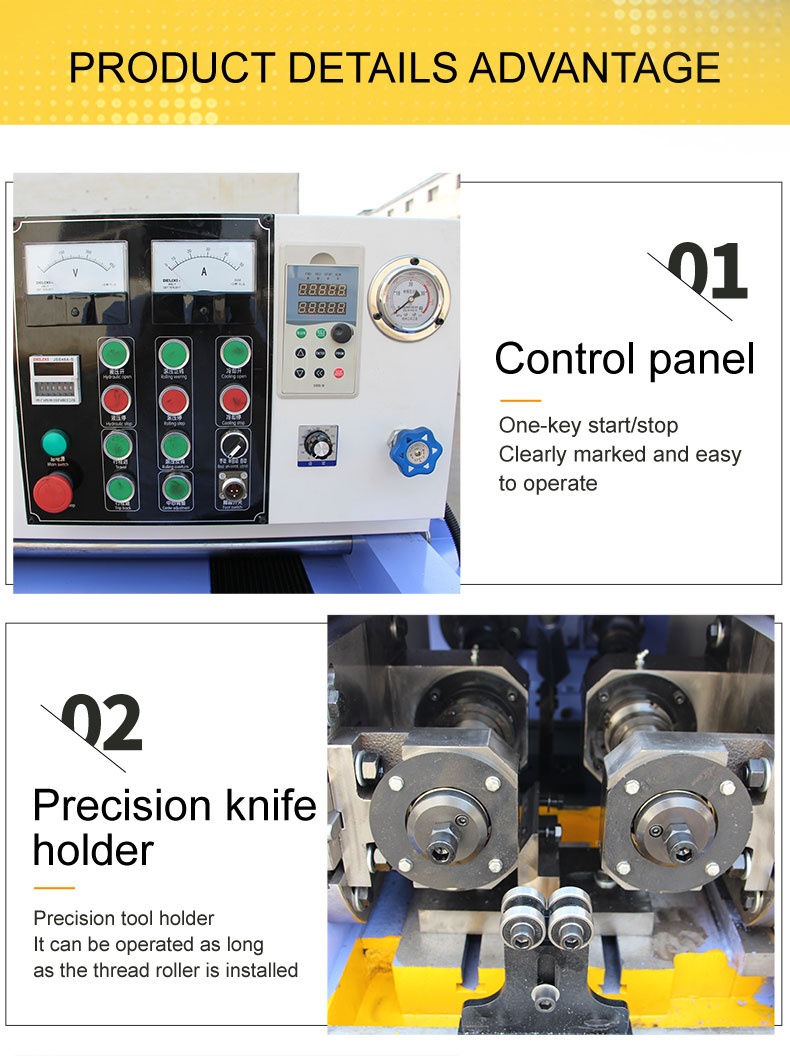

Understanding the Functionality and Efficiency of Thread Rolling Machines in Industrial Applications

The Importance of Thread Rolling Machines in Modern Manufacturing

In the realm of manufacturing, precision and efficiency are paramount. Among the equipment that has revolutionized production processes, thread rolling machines stand out as a critical tool for creating high-quality threaded components. These machines utilize a unique process that enhances productivity, reduces waste, and improves the overall quality of the finished products.

Understanding the Technology

Thread rolling is a cold-forming process that forms threads on a workpiece by moving it between two dies. Unlike traditional cutting methods, which remove material to create threads, thread rolling compresses the material to form the desired shape. This not only conserves material but also leads to a stronger, more durable product; the resulting threads are typically tighter and more uniform than those produced by cutting.

The working principle of thread rolling machines revolves around high pressure and precise motion. The workpiece, often made of metal, is fed through the machine where it encounters rotating dies. These dies impart a series of precise, controlled movements to shape the material into threads. This method is especially effective for mass production, allowing manufacturers to produce large volumes of threaded components quickly and consistently.

Advantages Over Traditional Methods

1. Increased Strength One of the most significant benefits of using thread rolling machines is the enhancement of material strength. The process aligns the grain structure of the metal, resulting in tougher threads that are less prone to failure under stress.

2. Improved Surface Finish The cold-forming process leaves a smooth surface on the threaded areas, which reduces the need for additional finishing processes. As a result, manufacturers save time and labor costs while ensuring that products meet stringent quality standards.

thread rolling machine working quotes

3. Material Efficiency Traditional cutting methods can produce significant waste, as material is removed to create threads. Thread rolling, on the other hand, retains the bulk of the material, making it a more sustainable choice in terms of resource utilization.

4. High Production Rate Thread rolling machines can operate at high speeds, which is crucial for industries that require large quantities of threaded products within tight deadlines. This efficiency allows manufacturers to enhance their output and meet market demands more effectively.

5. Versatility Modern thread rolling machines can accommodate a variety of shapes and sizes, making them suitable for a wide array of applications. From small fasteners to large bolts, these machines can adapt to different manufacturing needs, providing flexibility in production.

Applications in Various Industries

The applications of thread rolling machines span numerous industries, including automotive, aerospace, construction, and electronics. In the automotive sector, for instance, thread-rolled components such as bolts and screws play critical roles in assembling vehicles, ensuring safety and reliability. Similarly, in the aerospace industry, lightweight yet strong threaded parts are essential for aircraft performance and durability.

Additionally, the increasing demand for high-quality threaded components in medical devices and equipment further underscores the significance of thread rolling machines. As the need for accuracy and reliability grows, manufacturers are turning to these machines to fulfill stringent regulatory requirements.

Conclusion

In conclusion, thread rolling machines are indispensable in modern manufacturing due to their ability to produce strong, precise, and high-quality threaded components efficiently. As industries continue to evolve and demand higher performance from their products, the role of thread rolling technology will only become more prominent. Embracing these machines not only enhances productivity but also contributes to sustainable manufacturing practices, making them a vital asset in today’s competitive market environment. With ongoing advancements in technology, we can expect thread rolling machines to further enhance manufacturing capabilities, driving innovation and excellence across various sectors.