-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

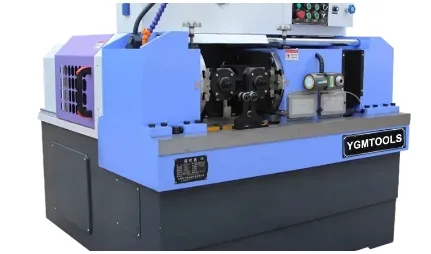

Vertical Thread Rolling Machine for Modern Manufacturing

In the dynamic world of industrial fastener production, the vertical thread rolling machine is rapidly becoming the preferred choice for manufacturers seeking higher output, smaller footprints, and more efficient operation. Unlike traditional horizontal setups, the vertical configuration uses gravity to assist with part feeding and positioning, resulting in smoother, more reliable threading processes.

The vertical thread rolling machine is especially popular in environments that demand high-speed production with precise, repeatable results. By aligning components vertically, these machines enable faster loading and unloading of workpieces, minimize machine vibrations, and provide more consistent thread profiles. This makes them highly suitable for applications in the automotive, aerospace, and construction hardware industries.

Another key advantage is that vertical machines typically occupy less floor space. In production lines where square footage is at a premium, this design allows for denser machinery layouts, increasing the overall throughput of a facility without requiring structural expansion. Integration with robotic arms and automatic feeders is also simpler and more stable with vertical models, allowing for seamless automation.

Thanks to modern innovations in die design and machine controls, the vertical thread rolling machine now offers greater flexibility in handling different workpiece materials and geometries. Whether threading carbon steel bolts or stainless steel rods, manufacturers benefit from excellent surface finishes, reduced material stress, and minimized scrap rates.

For companies striving for a lean, automated, and future-ready production system, transitioning to a vertical thread rolling machine is a highly strategic move. The combination of mechanical efficiency, space savings, and adaptability positions it as a cornerstone of next-generation threading operations.

Optimizing Production Through a Smart Thread Rolling Machine Setup

A successful operation with any thread rolling system starts with the correct thread rolling machine setup. This crucial phase determines how accurately and efficiently the machine will produce threaded components. Poor setup can lead to thread inconsistencies, premature die wear, and even machine downtime. On the other hand, a well-executed setup can drastically enhance part quality, reduce production interruptions, and increase die life.

Setting up a vertical thread rolling machine begins with selecting the right dies for the material and thread profile. Dies must be precisely aligned to ensure uniform pressure distribution during the rolling process. Many modern machines include optical alignment tools or digital setup guides that assist technicians in achieving perfect die positioning within minutes.

Feeding mechanisms are also integral to setup success. With a vertical thread rolling machine, gravity-fed systems and vertical loading trays are often used to simplify part handling. Automatic feeders should be synchronized with the die cycle to ensure smooth part transfer and minimal misfeeds. Lubrication lines must be tested and cleaned before startup, as any contaminants in the lubricant could affect surface finish or tool wear.

Once all physical components are adjusted, software configuration takes place. Many machines now store multiple threading programs, allowing operators to quickly switch between product types with minimal reconfiguration. Properly setting thread pitch, speed, and die rotation angle in the software interface is the final step in achieving a repeatable and optimized threading process.

Choosing the Right Thread Rolling Machine Manufacturer for Your Needs

Selecting a trustworthy thread rolling machine manufacturer is one of the most critical decisions in any industrial investment. Beyond just supplying a piece of equipment, the manufacturer becomes a long-term partner in your production success—offering technical support, spare parts, and customization options tailored to your specific applications.

A leading thread rolling machine manufacturer typically offers a wide portfolio of models, from basic semi-automatic machines to fully automated vertical thread rolling machines designed for lights-out production. They also provide expert consultation during the selection process, helping you identify the ideal machine based on your throughput, materials, product types, and available floor space.

In addition to machinery, a reliable thread rolling machine manufacturer should also provide installation and training services. They may dispatch technicians to your facility for setup and calibration, followed by operator training sessions on correct machine usage, maintenance, and troubleshooting. Some even offer remote diagnostics or IoT-enabled support systems that let you monitor machine health in real time.

Global service support is another hallmark of a strong manufacturer. Whether your facility is in North America, Europe, or Asia, prompt access to parts and technical assistance can make or break your operational efficiency. Always evaluate not just the equipment, but the service culture and responsiveness of the manufacturer before committing to a purchase.

The Role of Automation in Modern Vertical Thread Rolling Machine Lines

Automation is reshaping the future of manufacturing, and the vertical thread rolling machine is perfectly suited for integration into intelligent, high-efficiency production lines. With vertical orientation facilitating gravity-assisted part movement, these machines are ideal for use with robotic pickers, vibratory bowl feeders, and conveyor systems.

Modern factories demand flexibility, speed, and consistency, and the latest vertical thread rolling machines are engineered to deliver all three. Automatic part loading systems reduce labor requirements and eliminate the risk of human error in feeding components. This is especially important for large-scale production where continuous operation is needed across multiple shifts.

The vertical configuration also supports better ergonomics for operators. With all critical components accessible at eye level, maintenance and inspection tasks can be performed faster and more safely. Combined with energy-efficient drives and lubrication systems, these machines offer significant cost savings in long-term operation.

When planning an automated production line, your thread rolling machine setup should be designed for maximum throughput and minimal downtime. By working closely with a qualified thread rolling machine manufacturer, you can design a customized automation strategy that balances performance with reliability—giving your business a competitive edge in today’s demanding market.

Why Vertical Thread Rolling Machines Are the Future of Fastener Production

As industries continue to evolve with demands for faster delivery, higher accuracy, and lower operating costs, the vertical thread rolling machine stands out as the future of fastener and threaded component production. Its benefits go beyond space savings or alignment advantages—it’s about unlocking a more efficient and scalable production method.

One of the most compelling reasons to choose vertical over horizontal thread rolling is the reduction in material deformation. Because gravity naturally supports the part during the threading process, vertical machines experience less lateral stress, leading to better alignment and cleaner threads. This is particularly useful for components with critical dimensional tolerances, such as aerospace fasteners or precision medical screws.

Moreover, as product variety increases, manufacturers need machines that can quickly adapt to new designs. With modular die systems and programmable threading profiles, the vertical thread rolling machine can handle everything from metric and imperial threads to custom profiles like ACME or trapezoidal threads. This flexibility empowers facilities to meet changing customer demands without needing a complete line overhaul.

As the industry becomes more digitalized, features like real-time monitoring, remote diagnostics, and cloud-based performance reporting will become standard. Many forward-thinking manufacturers are already embedding these capabilities into their vertical threading machines, allowing users to monitor uptime, energy usage, and tool wear from any location.

For facilities undergoing lean transformations or scaling up production, the vertical thread rolling machine provides a smart, reliable foundation. Its mechanical advantages, combined with modern automation capabilities and simplified thread rolling machine setup, make it the obvious choice for manufacturers looking to future-proof their operations.

FAQs About Vertical Thread Rolling Machines and Setup

What are the main advantages of using a vertical thread rolling machine?

A vertical thread rolling machine offers better part alignment, gravity-assisted feeding, reduced machine footprint, and easier integration into automated lines. Its upright structure allows for faster setup and more ergonomic operation, while producing consistently high-quality threads with less lateral deformation. These machines are especially effective in high-volume fastener production environments.

How do I perform an optimal thread rolling machine setup?

An effective thread rolling machine setup involves precise die alignment, pressure calibration, proper lubrication, and software configuration. Technicians must ensure dies are aligned to avoid uneven threads and wear. Calibrating pressure correctly is vital to forming threads without damaging parts. Most modern machines include touchscreen interfaces and program memory to simplify and speed up setup.

What should I look for in a thread rolling machine manufacturer?

A reliable thread rolling machine manufacturer should offer quality equipment, certifications (ISO, CE), technical support, global parts availability, and customization services. Look for manufacturers that provide installation, operator training, and remote support. You should also assess their experience in your industry and evaluate machine demos or virtual tours before making a decision.

Can a vertical thread rolling machine handle different types of threads?

Yes, a vertical thread rolling machine can be equipped with different dies and programming to handle a variety of thread types, including standard metric, UNC/UNF, ACME, and trapezoidal threads. This versatility makes it suitable for both standardized and customized production, especially when using modular die systems and programmable PLCs for quick adjustments.

Is automation compatible with vertical thread rolling machines?

Absolutely. The vertical design makes these machines particularly well-suited for automation. They can easily integrate with robotic loaders, bowl feeders, and conveyor belts. Many vertical machines also support digital I/O connections, allowing seamless integration into smart production systems with real-time monitoring and MES communication.