-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

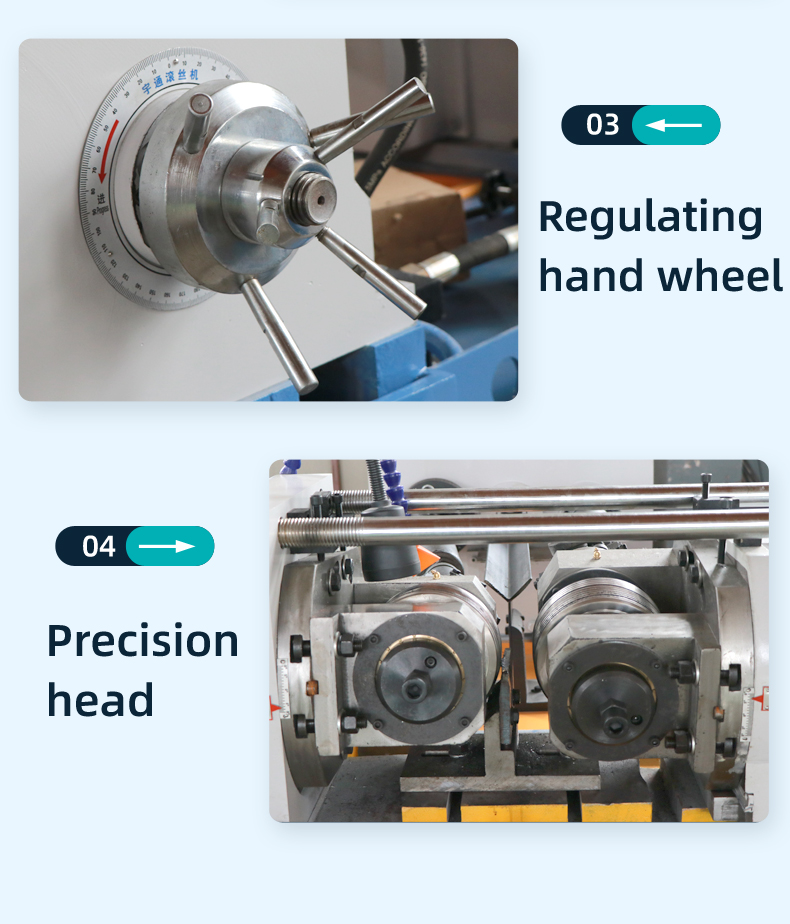

wholesale 3 die thread rolling machine

The Wholesale Die Thread Rolling Machine A Key Tool for Precision Engineering

In the realm of manufacturing and engineering, precision plays a crucial role in ensuring the quality and performance of components. One essential tool that has gained significant traction in this sector is the die thread rolling machine. Often utilized in various industries, such as automotive, aerospace, and construction, these machines facilitate the creation of high-quality threaded materials efficiently and effectively.

Understanding Die Thread Rolling

Die thread rolling involves a process where a cylindrical workpiece is transformed into a threaded tube or rod by applying pressure from hardened dies. This technique is distinct from traditional machining methods, such as cutting or grinding, as it utilizes a cold-forming process that enhances the material's strength while retaining its integrity. By pushing the metal into the desired shape, thread rolling reduces waste and improves the overall efficiency of production.

Advantages of Using Die Thread Rolling Machines

1. Enhanced Strength One of the primary advantages of die thread rolling is that it improves the mechanical properties of the material. The rolling action compacts the metal's grain structure, resulting in enhanced tensile strength and superior fatigue resistance. This makes rolled threads more durable compared to cut threads, which can suffer from weak points.

2. Cost Efficiency Wholesale die thread rolling machines are a cost-effective investment for manufacturers. By minimizing material waste and reducing the time needed for production, these machines help businesses achieve significant savings. The high-speed operation of thread rolling machines further accelerates production cycles, allowing manufacturers to meet rising demands without compromising quality.

3. Precision and Consistency These machines ensure high precision in the production of threaded components. With advanced technology, modern die thread rolling machines can produce consistently accurate threads, adhering to strict specifications. This level of precision is crucial in industries where fitting and fastening require exact tolerances.

4. Versatility Die thread rolling machines are versatile tools suitable for various materials including steel, aluminum, and brass. They can create different thread profiles, such as UNC, UNF, metric threads, and many others. This adaptability makes them ideal for manufacturers who cater to diverse client needs.

wholesale 3 die thread rolling machine

5. Environmentally Friendly The cold-forming process of die thread rolling generates less scrap compared to traditional machining techniques. By using the material more efficiently, manufacturers not only save costs but also contribute to environmental sustainability. This dual benefit is increasingly important as industries strive to implement greener practices.

Choosing the Right Die Thread Rolling Machine

When selecting a wholesale die thread rolling machine, manufacturers should consider several factors

- Capacity and Size Understand the maximum size and weight of the workpieces the machine can handle. This will depend on the specific requirements of your production needs.

- Thread Types Ensure the machine can produce the specific thread designs required for your applications.

- Automation Features Look for machines with advanced automation features to optimize productivity and minimize labor costs.

- Brand Reputation Choose a machine from a reputable manufacturer known for producing reliable and efficient equipment.

Conclusion

The wholesale die thread rolling machine has become a cornerstone of modern manufacturing processes, especially in industries demanding high precision and durability. Its ability to produce strong and consistent threaded components while minimizing waste makes it an invaluable asset for manufacturers looking to enhance their production capabilities. As technology continues to advance, these machines will likely evolve, offering even greater efficiency and versatility, ensuring their dominance in the manufacturing landscape for years to come.