-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

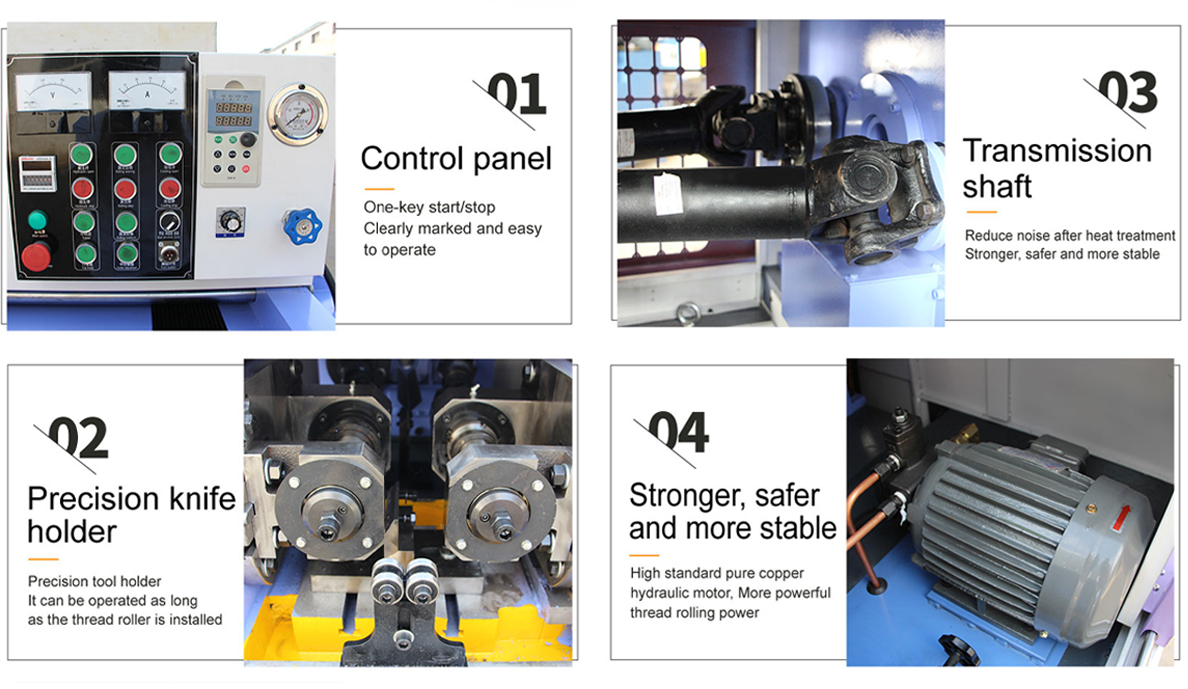

Wholesale Prices for Hydraulic Thread Rolling Machines and Their Features

Understanding the Price Dynamics of Wholesale Hydraulic Thread Rolling Machines

In the modern industrial landscape, the demand for precision engineering has escalated dramatically. One of the pivotal machines driving this evolution is the hydraulic thread rolling machine. These machines are essential in manufacturing threaded components that meet high standards of accuracy and durability. As with any industrial equipment, understanding the pricing dynamics of wholesale hydraulic thread rolling machines is crucial for manufacturers and businesses looking to optimize their production processes.

What is a Hydraulic Thread Rolling Machine?

A hydraulic thread rolling machine is a type of industrial equipment used to create threads on metal and other materials through a process known as thread rolling. Unlike traditional cutting methods, thread rolling is a cold-forming process that displaces material to create threads, which enhances the strength of the components while minimizing waste. These machines operate using hydraulic power to apply high pressure, thus ensuring the threads are precisely formed.

Factors Influencing Prices

Several factors impact the pricing of wholesale hydraulic thread rolling machines

1. Machine Specifications The size, capacity, and features of the machine are significant determinants of its price. High-capacity machines that can handle larger materials or produce precise threads more quickly tend to be more expensive.

2. Brand Reputation Established brands with a track record of reliability and performance often command higher prices due to the trust they have built in the marketplace. Brands that provide good after-sale support and warranties can also justify higher price points.

3. Material and Construction Quality The materials used in the making of the machine, such as high-grade steel and advanced hydraulic components, affect the cost. Machines built with superior materials tend to be more durable and efficient, albeit at a higher price.

4. Technological Features Modern hydraulic thread rolling machines often come equipped with advanced technology, including digital controls, automated systems, and enhanced safety features. These technological advancements can significantly increase the price of the machines.

5. Market Demand The overall demand for hydraulic thread rolling machines in the market plays a crucial role in pricing. In periods of high demand, prices may rise due to limited supply, while in slower markets, prices may decrease to encourage sales.

wholesale hydraulic thread rolling machine price

6. Geographical Location Pricing can also vary based on geographical considerations. Import taxes, shipping costs, and local market conditions will influence the wholesale prices of these machines in different regions.

Price Ranges

The price of wholesale hydraulic thread rolling machines can vary widely based on the factors mentioned above. Generally, one can expect to find machines priced from a few thousand dollars for basic models to well over $100,000 for high-end, sophisticated units capable of producing high volumes of threaded components with precision.

Tips for Purchasing

When considering the purchase of a hydraulic thread rolling machine, it is essential to evaluate several aspects to ensure a worthwhile investment

- Assess Your Needs Determine the production capacity and specifications required for your operations before delving into the market. Understanding your needs will help focus your search on machines that provide the best value.

- Research and Compare Take the time to compare different models, brands, and their respective features. Look at customer reviews and industry forums for insight into machine performance and reliability.

- Consider Used Equipment For companies with tighter budgets, exploring the option of purchasing used or refurbished machines can lead to substantial savings while still achieving operational goals.

- Negotiate for Bulk Orders Many manufacturers offer significant discounts for bulk purchases. If your business is planning to scale, inquire about wholesale pricing and potential discounts.

Conclusion

Hydraulic thread rolling machines are vital for producing high-quality threaded components in numerous industries. By understanding the factors that influence pricing and conducting thorough research, businesses can make informed decisions that align with both their production needs and budget constraints. As the manufacturing sector continues to evolve, investing in the right equipment will ultimately contribute to operational efficiency and success.