-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Wholesale Thread Rolling Machines for Efficient Rod Production and Manufacturing Solutions

The Role of Wholesale Rod Thread Rolling Machines in Modern Manufacturing

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. Among the tools that have gained prominence in achieving these goals is the wholesale rod thread rolling machine. This machine plays a crucial role in the production of threaded rods and precision fasteners, essential components in various industries such as automotive, construction, and machinery. This article explores the significance, functionality, and benefits of wholesale rod thread rolling machines in modern manufacturing.

Understanding Thread Rolling

Thread rolling is a cold-forming process that creates threads on a rod or a cylindrical workpiece by deforming the material, rather than cutting it. This method is advantageous because it maintains the integrity of the material, improving its mechanical properties and minimizing waste. The process is particularly favored for producing high-volume, high-precision threaded components.

Functionality of Rod Thread Rolling Machines

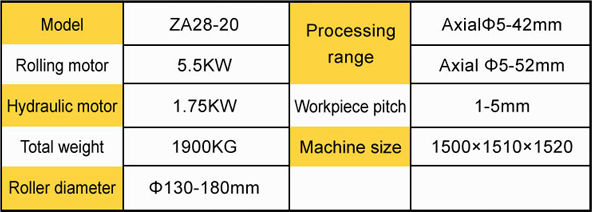

Wholesale rod thread rolling machines are specifically designed to cater to the mass production of threaded rods. These machines feature several key components, including rollers, dies, and a feeding mechanism. The rods are fed into the machine, where they pass between two or more rotating rollers that exert pressure to form the desired thread profile.

The versatility of these machines allows them to produce various thread sizes and pitches, making them suitable for multiple applications

. Advanced models incorporate computerized controls, enabling manufacturers to program and adjust settings precisely, thus increasing production speed while maintaining high quality.Advantages of Using Wholesale Rod Thread Rolling Machines

wholesale rod thread rolling machine

1. Cost-Efficiency One of the most significant advantages of wholesale rod thread rolling machines is their cost-effectiveness. By producing a higher volume of threads in less time compared to traditional machining methods, manufacturers can save on labor and operational costs. Furthermore, the cold-forming process results in less material waste, maximizing resource utilization.

2. Enhanced Strength and Durability Because thread rolling is a cold-forming process, it preserves the grain structure of the metal, enhancing its strength and durability. This is particularly important in applications where high tensile strength is necessary, such as in construction and automotive industries.

3. Improved Precision The use of specialized dies and rollers ensures that the threads produced are highly uniform and accurate, reducing the likelihood of defects and the need for secondary operations. This precision is critical in ensuring that threaded components fit together correctly and function as intended.

4. Flexibility in Production Wholesale rod thread rolling machines can easily be adjusted to create different thread profiles, pitches, and sizes, allowing manufacturers to respond quickly to changing market demands. This flexibility is vital in today’s manufacturing environment, where customization and speed are increasingly valued.

5. Reduced Lead Times With automated features and high production rates, these machines significantly shorten lead times. Manufacturers can fulfill larger orders more swiftly, providing a competitive edge in a market that often demands quick turnaround times.

Conclusion

Wholesale rod thread rolling machines are a cornerstone of modern manufacturing, providing a powerful solution for producing high-quality threaded components with efficiency and precision. Their ability to produce strong, durable, and precise threads makes them essential for industries where reliability is crucial. As technology evolves, these machines are likely to incorporate even more advanced features, further enhancing their capabilities and impact in the manufacturing sector. For businesses looking to optimize their production processes, investing in a wholesale rod thread rolling machine is not just a strategic move; it is a pathway to increased efficiency, reduced costs, and improved product quality. As we continue to advance into an era of smart manufacturing, the importance of these machines will only grow, establishing them as vital tools for the future of production.