-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

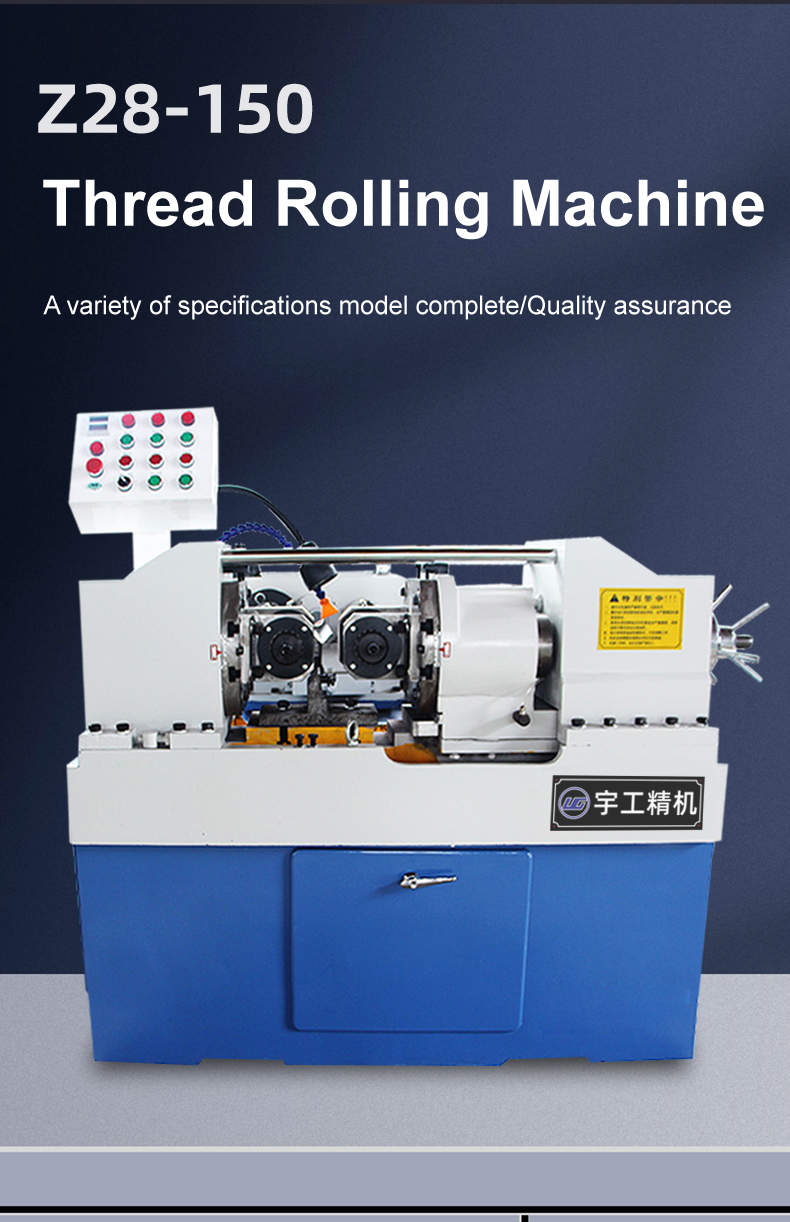

Wholesale Steel Thread Rolling Machines for Efficient Manufacturing Processes

The Significance of Wholesale Steel Thread Rolling Machines in Modern Manufacturing

In the realm of manufacturing and industrial processes, precision and efficiency play critical roles. Among the myriad of machines that facilitate these qualities, wholesale steel thread rolling machines have emerged as pivotal tools. These machines are specifically designed for creating threads on steel components, significantly enhancing manufacturing processes across various sectors, including automotive, aerospace, and construction.

Understanding Thread Rolling

Thread rolling is a cold forming process that produces threads on metal workpieces. Unlike traditional cutting methods, rolling machines create threads by deforming the material under high pressure, which results in a stronger and more durable product. This method is particularly advantageous when working with steel, as it not only enhances the integrity of the threads but also minimizes material waste.

The process involves two or three dies that are shaped to the desired thread profile. When the steel component is rolled between these dies, it acquires the desired thread pattern without losing bulk material, leading to significant cost savings and efficiency improvements in manufacturing.

Advantages of Wholesale Steel Thread Rolling Machines

1. Cost Efficiency By producing threads without cutting away material, manufacturers reduce the overall material cost. Additionally, the mechanical efficiency of thread rolling machines allows for higher production rates.

2. Enhanced Strength The cold forming process improves the grain structure of the steel, resulting in threads that are not only stronger but also possess greater fatigue resistance compared to cut threads. This is particularly crucial in applications where high-load bearing is essential.

3. Precision and Consistency These machines are capable of producing threads with precise measurements and tolerances, resulting in high-quality components that meet exact specifications. This consistency is vital in industries such as aerospace, where even slight deviations can lead to catastrophic failures.

wholesale steel thread rolling machine

4. Versatility Wholesale steel thread rolling machines can accommodate a variety of thread types, including internal and external threads. This makes them suitable for diverse applications across multiple industries, thereby enhancing their utility in manufacturing environments.

5. Environmentally Friendly The reduction of material waste during the thread rolling process contributes to more sustainable manufacturing practices. This not only helps companies to lower their raw material costs but also aligns with global efforts toward environmental sustainability.

Applications in Various Industries

The use of wholesale steel thread rolling machines spans numerous industries. In the automotive sector, they are essential for producing threaded fasteners that are integral to vehicle assembly. Aerospace manufacturers rely on these machines to create high-strength components that meet rigorous safety and performance standards. Additionally, in the construction industry, threaded steel rods and anchors produced through thread rolling are used to enhance the structural integrity of buildings and infrastructure.

Choosing the Right Machine

For manufacturers looking to invest in wholesale steel thread rolling machines, several factors should be considered. First, the machine's specifications, such as rolling capacity, speed, and the types of threads it can produce, must align with the intended application. Secondly, evaluating the reliability and maintenance requirements of the machine is crucial for minimizing downtime and ensuring longevity. Lastly, considering the supplier’s reputation and support services can help in making an informed decision.

Conclusion

In conclusion, wholesale steel thread rolling machines are invaluable assets in modern manufacturing, offering a combination of cost efficiency, strength, precision, and versatility. As industries continue to seek ways to optimize production processes and uphold quality standards, the role of thread rolling machines will undoubtedly expand. Investing in such technology not only enhances operational efficiency but also positions manufacturers to meet the evolving demands of the market. By leveraging the advantages of wholesale steel thread rolling machines, companies can stay competitive and drive innovation across their sectors.