-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

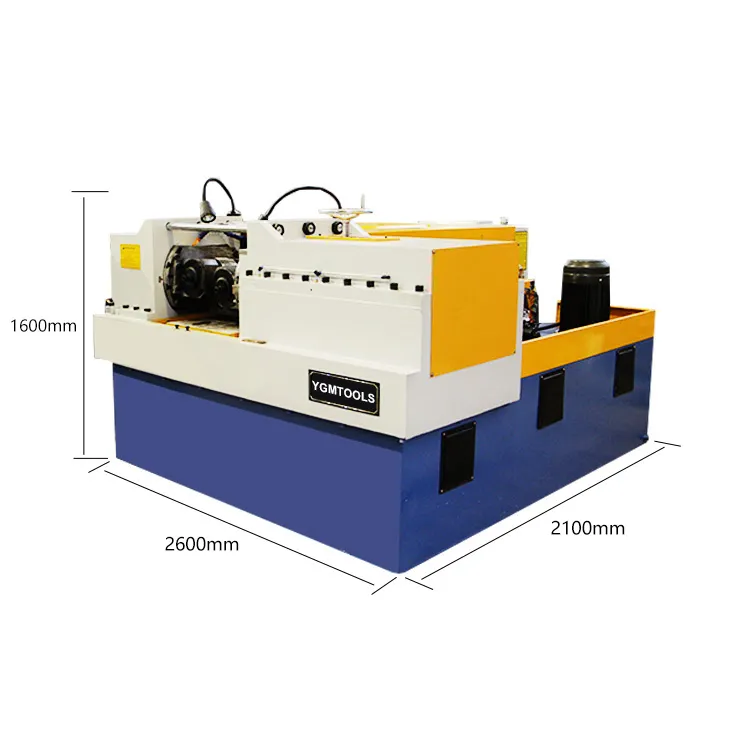

Suppliers of Wire Thread Rolling Machines for Precision Manufacturing

The Importance of Wire Thread Rolling Machines and Key Suppliers in the Industry

In the manufacturing and fabrication sectors, the demand for precision-engineered components is ever-increasing. One essential piece of equipment that has proven indispensable for producing high-quality threaded fasteners is the wire thread rolling machine. These machines are designed to create threads on wire, transforming plain metal into critical components needed in various applications, from automotive to construction.

Wire thread rolling is a cold forming process that involves the deformation of the material to create screw threads. This method not only enhances the mechanical properties of the material but also improves the overall efficiency of production. By using wire thread rolling machines, manufacturers can achieve superior precision and surface finish compared to traditional cutting methods. This results in reduced material waste and lower production costs, making it an attractive option for businesses looking to optimize their operations.

Given the technical complexity and operational efficiency required in the manufacturing process, sourcing high-quality wire thread rolling machines is vital. Numerous suppliers have emerged in the market, offering various models and features. When selecting a supplier, manufacturers should consider several factors, such as machine performance, durability, after-sales service, and technical support.

wire thread rolling machine suppliers

Several leading suppliers excel in providing wire thread rolling machines. Companies like Acme Manufacturing Company, National Machinery LLC, and TRUCUT are known for their innovative designs and robust machines. They offer models suitable for different wire sizes and threading applications, catering to diverse industrial needs. Furthermore, these suppliers often provide customization options, allowing businesses to tailor machines to their specific requirements.

Another significant benefit of working with established suppliers is access to comprehensive after-sales support. Reputable suppliers usually offer training programs, maintenance services, and spare parts availability, which are crucial for ensuring the longevity and efficiency of the machines. This level of support can significantly reduce downtime and repair costs, ultimately contributing to increased productivity.

The rise of the global market has also led to the emergence of various international suppliers. Companies from countries like Germany, Japan, and China are making their mark by providing advanced technology and competitive pricing, further widening the options available to manufacturers. However, it is essential to perform due diligence on these suppliers to ensure they meet industry standards and provide reliable products.

In conclusion, wire thread rolling machines play a pivotal role in the manufacturing industry, enabling the efficient production of high-quality threaded components. Selecting the right supplier is crucial for optimizing manufacturing processes and maintaining competitive advantage. By prioritizing factors like machine performance, support services, and supplier reliability, businesses can make informed decisions that will serve them well in an evolving industrial landscape. As technology continues to advance, investing in quality machinery and partnerships with reputable suppliers will remain essential for success in this critical sector.