-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

jun . 17, 2024 12:45

Back to list

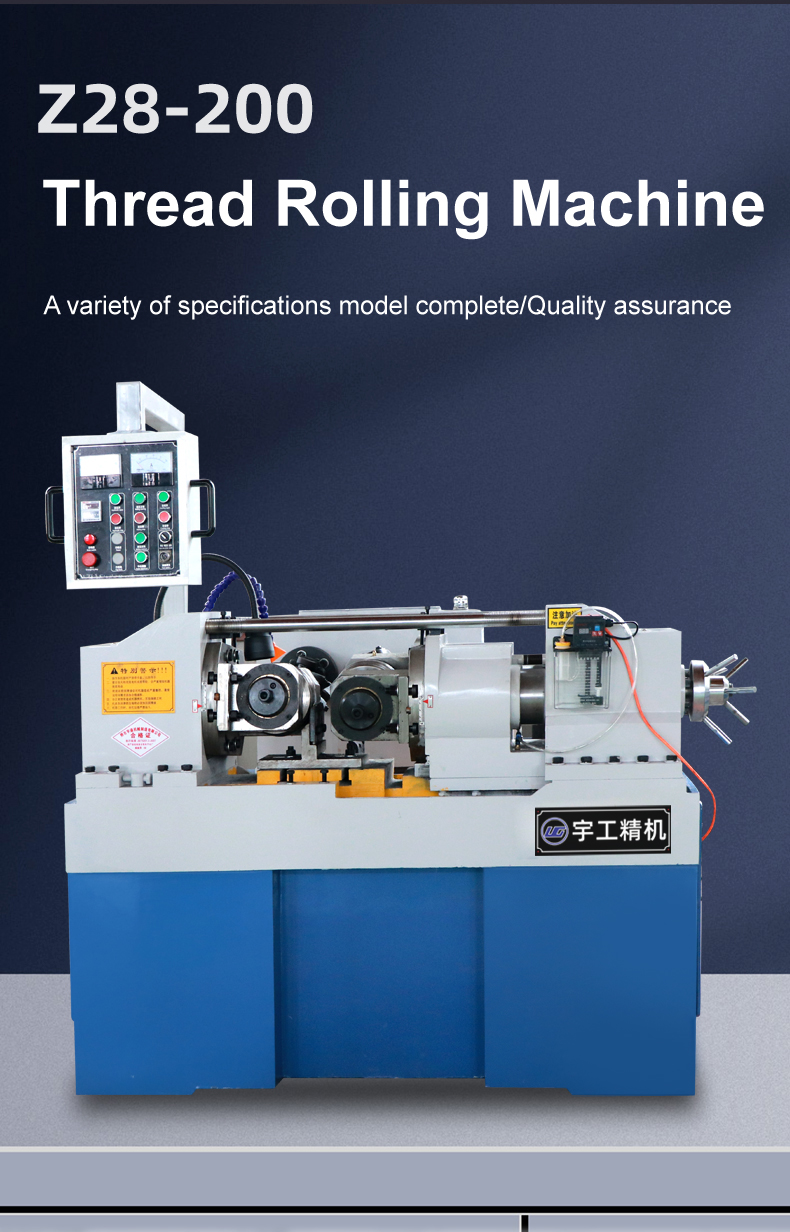

Thread rolling machine flat die price list available.

Navigating the Price List for Thread Rolling Machine Flat Dies

In the world of metal forming and manufacturing, thread rolling machines play a crucial role in producing precision threads on various materials. One of the key components of these machines is the flat die, which is responsible for shaping the threads. For businesses looking to invest in or upgrade their thread rolling equipment, understanding the price list for flat dies is essential. In this article, we will explore the factors that influence the cost of thread rolling machine flat dies and provide insights into making informed purchasing decisions.

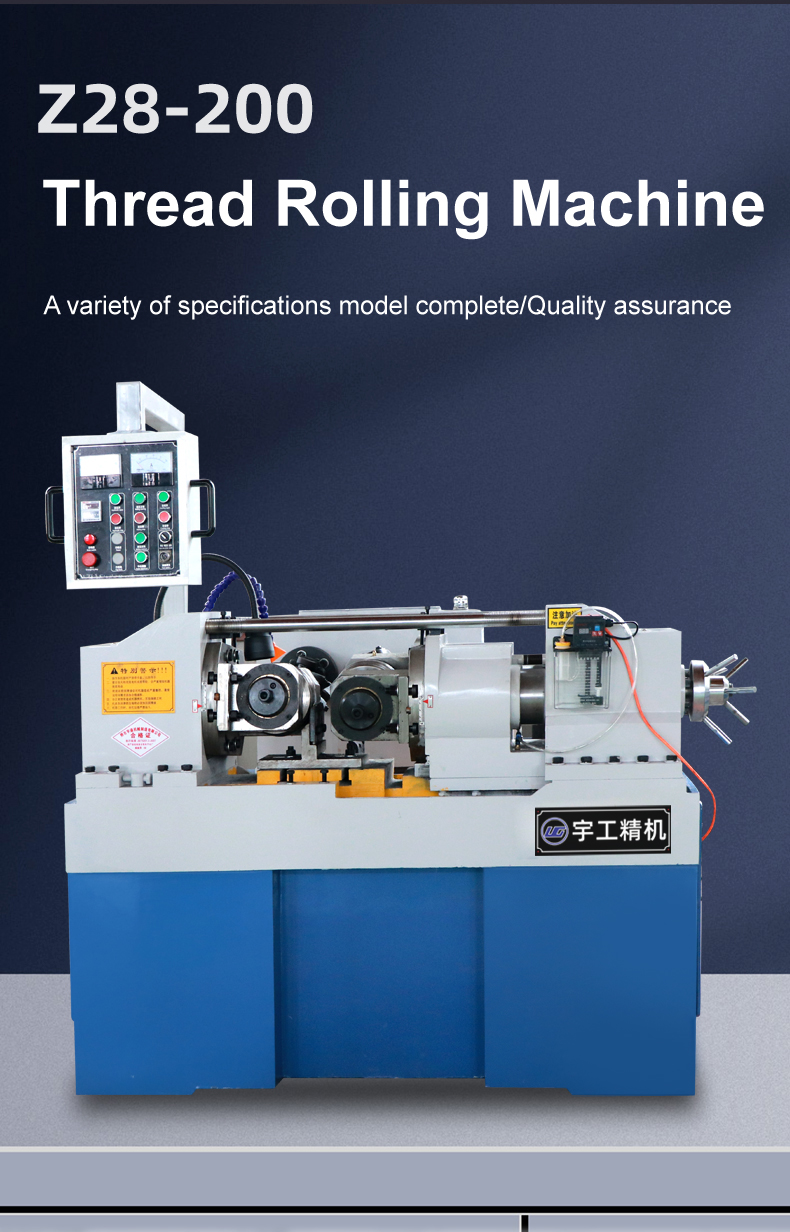

The price of thread rolling machine flat dies can vary significantly depending on several factors. Firstly, the material used in the construction of the die has a direct impact on its cost. High-quality materials such as high-speed steel (HSS) or tungsten carbide are more expensive than standard tool steel but offer superior durability and performance. As a result, businesses must weigh the initial investment against the long-term benefits of using higher-grade materials.

Secondly, the complexity of the thread profile also affects the price. Simpler thread designs require less intricate machining processes and are generally less expensive than complex profiles with multiple starts or unique shapes. Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times

Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times thread rolling machine flat die pricelist.

Another factor to consider is the size and capacity of the flat die. Larger dies capable of handling thicker materials or wider threads will naturally be more costly than their smaller counterparts. This is because they require more material and greater precision during manufacturing.

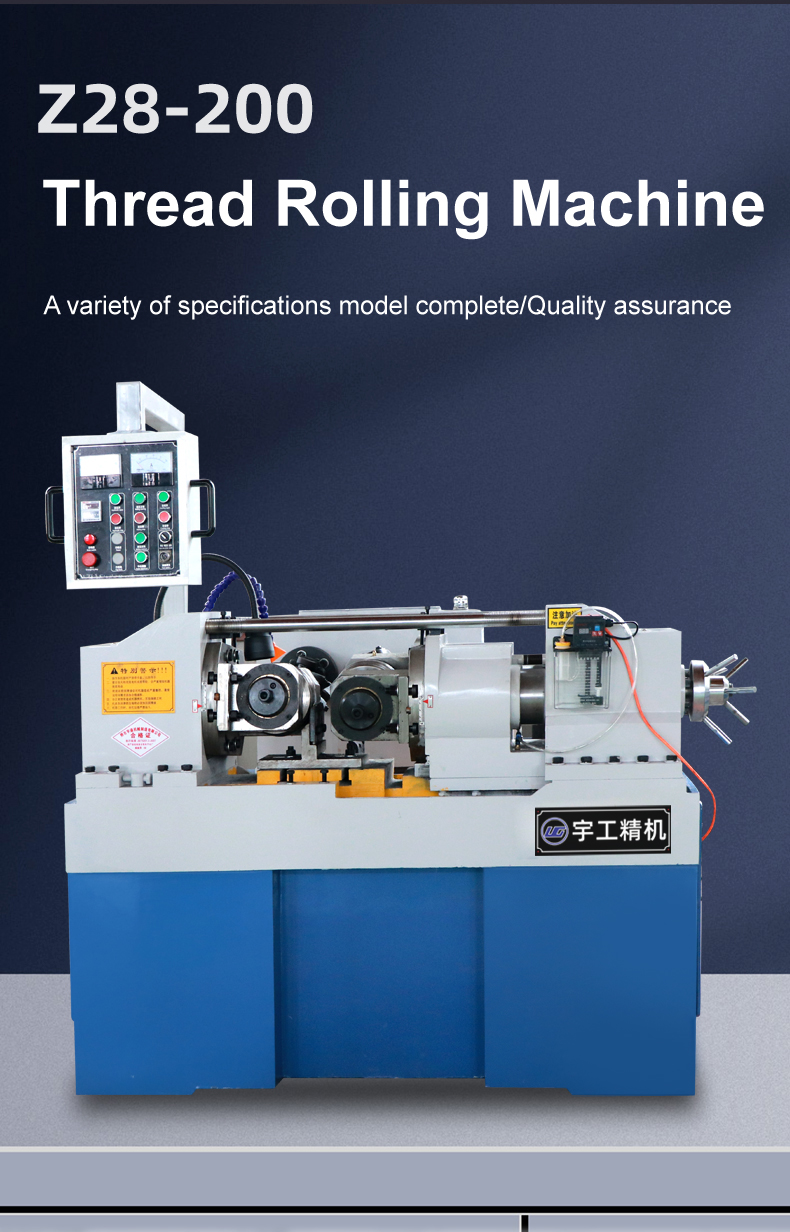

When reviewing a price list for thread rolling machine flat dies, it is important to compare not only the prices but also the specifications and capabilities of each option. Some manufacturers may offer competitive pricing but sacrifice on quality or after-sales service. It is advisable to request samples or demonstrations from reputable suppliers to ensure compatibility with existing equipment and satisfaction with the product's performance.

In conclusion, navigating the price list for thread rolling machine flat dies requires careful consideration of material quality, thread complexity, die size, and overall value for money. By taking into account these factors and engaging with reputable suppliers, businesses can make informed decisions that align with their production needs and financial constraints. Investing in the right flat die can lead to increased efficiency, improved product quality, and ultimately, a stronger bottom line for any manufacturing operation involved in thread rolling processes.

thread rolling machine flat die pricelist.

Another factor to consider is the size and capacity of the flat die. Larger dies capable of handling thicker materials or wider threads will naturally be more costly than their smaller counterparts. This is because they require more material and greater precision during manufacturing.

When reviewing a price list for thread rolling machine flat dies, it is important to compare not only the prices but also the specifications and capabilities of each option. Some manufacturers may offer competitive pricing but sacrifice on quality or after-sales service. It is advisable to request samples or demonstrations from reputable suppliers to ensure compatibility with existing equipment and satisfaction with the product's performance.

In conclusion, navigating the price list for thread rolling machine flat dies requires careful consideration of material quality, thread complexity, die size, and overall value for money. By taking into account these factors and engaging with reputable suppliers, businesses can make informed decisions that align with their production needs and financial constraints. Investing in the right flat die can lead to increased efficiency, improved product quality, and ultimately, a stronger bottom line for any manufacturing operation involved in thread rolling processes.

Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times

Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times Additionally, custom designs may incur additional costs due to the need for specialized tooling and longer production times thread rolling machine flat die pricelist.

Another factor to consider is the size and capacity of the flat die. Larger dies capable of handling thicker materials or wider threads will naturally be more costly than their smaller counterparts. This is because they require more material and greater precision during manufacturing.

When reviewing a price list for thread rolling machine flat dies, it is important to compare not only the prices but also the specifications and capabilities of each option. Some manufacturers may offer competitive pricing but sacrifice on quality or after-sales service. It is advisable to request samples or demonstrations from reputable suppliers to ensure compatibility with existing equipment and satisfaction with the product's performance.

In conclusion, navigating the price list for thread rolling machine flat dies requires careful consideration of material quality, thread complexity, die size, and overall value for money. By taking into account these factors and engaging with reputable suppliers, businesses can make informed decisions that align with their production needs and financial constraints. Investing in the right flat die can lead to increased efficiency, improved product quality, and ultimately, a stronger bottom line for any manufacturing operation involved in thread rolling processes.

thread rolling machine flat die pricelist.

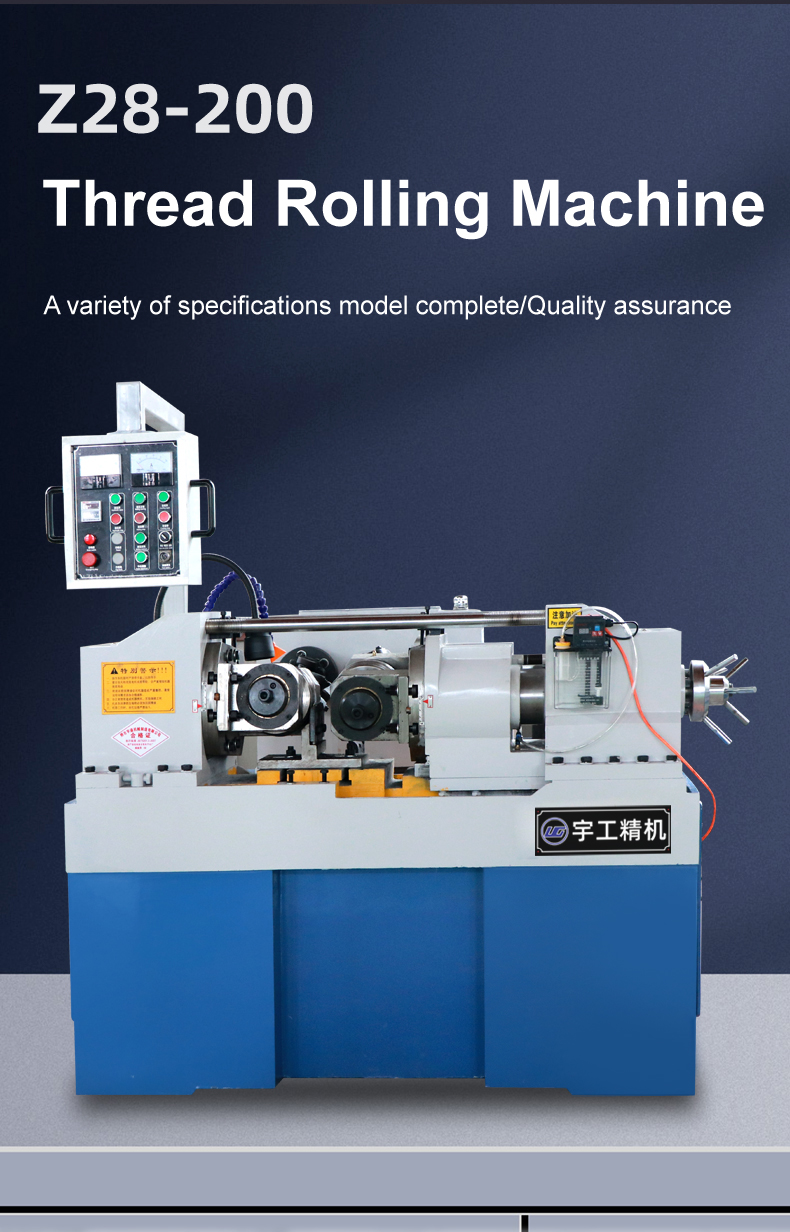

Another factor to consider is the size and capacity of the flat die. Larger dies capable of handling thicker materials or wider threads will naturally be more costly than their smaller counterparts. This is because they require more material and greater precision during manufacturing.

When reviewing a price list for thread rolling machine flat dies, it is important to compare not only the prices but also the specifications and capabilities of each option. Some manufacturers may offer competitive pricing but sacrifice on quality or after-sales service. It is advisable to request samples or demonstrations from reputable suppliers to ensure compatibility with existing equipment and satisfaction with the product's performance.

In conclusion, navigating the price list for thread rolling machine flat dies requires careful consideration of material quality, thread complexity, die size, and overall value for money. By taking into account these factors and engaging with reputable suppliers, businesses can make informed decisions that align with their production needs and financial constraints. Investing in the right flat die can lead to increased efficiency, improved product quality, and ultimately, a stronger bottom line for any manufacturing operation involved in thread rolling processes. Share:

Latest news

Applications of High-Speed Thread Rolling in Automotive

NewsMay.22,2025

Steel Bar Thread Rolling Machine Customization Options

NewsMay.22,2025

Vertical Thread Rolling Machines

NewsMay.22,2025

CNC Thread Rolling Machine Automation Advantages

NewsMay.22,2025

Market Demand Trends of Small Thread Rolling Machines

NewsMay.22,2025

Types of Thread Rolling Machines and Their Industrial Applications

NewsMay.22,2025