-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

automatic thread rolling machine suppliers

Exploring Automatic Thread Rolling Machine Suppliers A Key to Efficient Manufacturing

In the rapidly evolving world of manufacturing, efficiency, precision, and speed are paramount. Among the many processes that contribute to these goals, thread rolling has emerged as a highly efficient method for producing fasteners and various cylindrical components. The demand for high-quality automatic thread rolling machines has surged, leading manufacturers to seek reliable suppliers that can meet their production needs.

What is Thread Rolling?

Thread rolling is a cold-forming process that shapes materials into threads through the use of parallel, rotating dies. This method not only enhances the physical properties of the material, making it stronger and more durable, but it also minimizes waste compared to traditional machining methods. As industries continue to prioritize sustainability and cost-efficiency, the adoption of automatic thread rolling machines has gained traction.

The Role of Automatic Thread Rolling Machine Suppliers

Selecting the right supplier for automatic thread rolling machines is crucial for manufacturers looking to enhance their production capabilities. Top suppliers offer a range of machines suited for various applications, including different sizes, materials, and thread configurations. They can provide solutions tailored to specific manufacturing needs, ensuring that businesses can produce high-quality products efficiently.

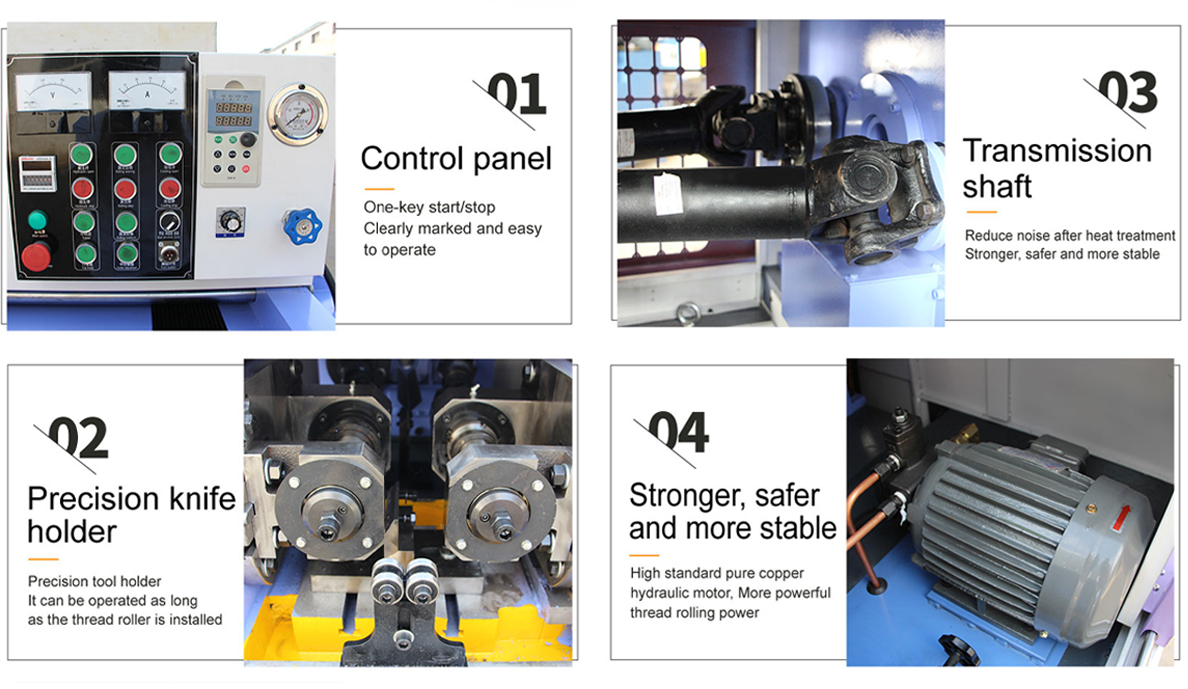

Key Features of Quality Thread Rolling Machines

1. Automation Automatic machines significantly reduce manual labor, allowing for continuous operation and increased output. Moreover, they ensure consistent quality across all produced pieces.

3. User-Friendly Interface Modern machines often come with intuitive controls and monitoring systems, making it easier for operators to set them up and maintain optimal performance.

automatic thread rolling machine suppliers

4. Durability and Maintenance Reliable suppliers will offer machines constructed from robust materials designed for long-term use under heavy production conditions. Additionally, they provide after-sales support, ensuring routine maintenance and addressing any potential issues promptly.

Finding the Right Supplier

When searching for a supplier of automatic thread rolling machines, manufacturers should consider several factors

- Reputation A supplier’s track record in delivering quality machines and customer service is crucial. Researching reviews and testimonials can provide insight into their reliability.

- Innovation Suppliers who keep abreast of technological advancements tend to offer machines that incorporate the latest features, optimizing efficiency and performance.

- Customization Options Every manufacturing process is unique. Suppliers who offer customization options can help tailor machines to specific requirements, enhancing overall productivity.

- After-Sales Support Exceptional after-sales service is vital for ensuring long-term success. A good supplier should provide training, maintenance, and quick resolution for any issues that may arise.

Conclusion

The right automatic thread rolling machine supplier can significantly impact the efficiency and quality of manufacturing processes. By investing time in selecting a reputable and capable supplier, manufacturers can enhance their production capabilities, leading to improved quality and satisfaction in the competitive marketplace. As industries evolve, the partnership with reliable suppliers will be pivotal in driving innovation and success in manufacturing.