-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

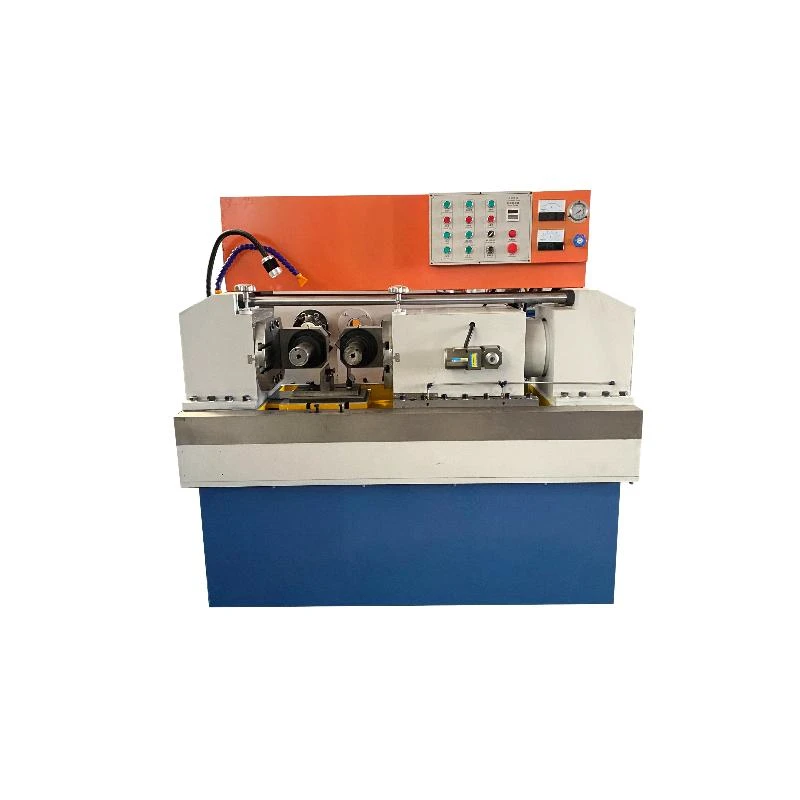

best circular thread rolling machine

Best Circular Thread Rolling Machines An Overview

In the ever-evolving manufacturing landscape, thread rolling has emerged as a vital process for producing high-quality threads on metal workpieces. Among the various types of machines available, circular thread rolling machines have gained considerable traction due to their efficiency, precision, and ability to handle a wide range of materials and sizes. This article explores the best circular thread rolling machines available in the market, emphasizing their features, benefits, and applications.

What is a Circular Thread Rolling Machine?

Circular thread rolling machines utilize a method known as thread rolling, where a workpiece is transformed into a threaded form by applying pressure through two rotating cylindrical dies. This process not only enhances the mechanical properties of the threaded portion (such as strength and fatigue resistance) but also provides excellent surface finishes. The circular design of the machine allows for multiple workpieces to be processed simultaneously, which can significantly boost productivity.

Key Features of Top Circular Thread Rolling Machines

1. High Precision The best circular thread rolling machines are engineered for precision, often featuring advanced CNC (Computer Numerical Control) systems. This level of control ensures that threads are rolled to exact specifications, reducing wastage and the need for secondary processes.

2. Versatility High-quality machines can accommodate various materials, including steel, aluminum, and brass, making them adaptable to different applications. Additionally, they can produce various thread forms, such as UN, metric, and custom threads.

3. Speed and Efficiency Modern circular thread rolling machines are designed for high-speed operation. The rolling process is faster compared to traditional cutting methods, allowing for increased throughput without compromising quality.

4. User-Friendly Interface Many contemporary models come equipped with intuitive user interfaces that simplify machine operation. This feature is essential for reducing training time and ensuring that operators can efficiently manage the machine settings.

best circular thread rolling machine

5. Durability and Low Maintenance The best machines are constructed from high-quality materials capable of withstanding the stresses of constant use. Low-maintenance designs help reduce downtime, ensuring that production schedules remain on track.

Benefits of Circular Thread Rolling Machines

- Enhanced Mechanical Properties The rolling process causes the workpiece grain structure to flow, which improves tensile strength and durability. This is particularly advantageous in applications where component reliability is critical. - Cost-Effectiveness Over time, the investment in a quality circular thread rolling machine pays off. The combination of reduced material waste and increased production speed translates into lower operational costs.

- Environmentally Friendly Circular thread rolling machines produce minimal waste compared to traditional machining techniques, making them a more sustainable option for manufacturers.

Applications of Circular Thread Rolling Machines

The versatility of circular thread rolling machines means they find applications across a wide range of industries, including

- Automotive Used for producing nuts, bolts, and various high-strength fasteners. - Aerospace Essential for creating components that require precise threads to withstand extreme conditions. - Construction Employed for manufacturing structural components that require high durability. - Electronics Used in the production of small precision screws and bolts.

Conclusion

Investing in a top-tier circular thread rolling machine can significantly enhance production capabilities for manufacturers across various sectors. With features like high precision, versatility, and efficiency, these machines are indispensable for meeting the demands of modern manufacturing. As technology continues to advance, the best circular thread rolling machines will evolve, integrating new innovations that further improve performance and sustainability in the production process. For businesses aiming to remain competitive in the industry, selecting a reliable circular thread rolling machine should be a top priority.