-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

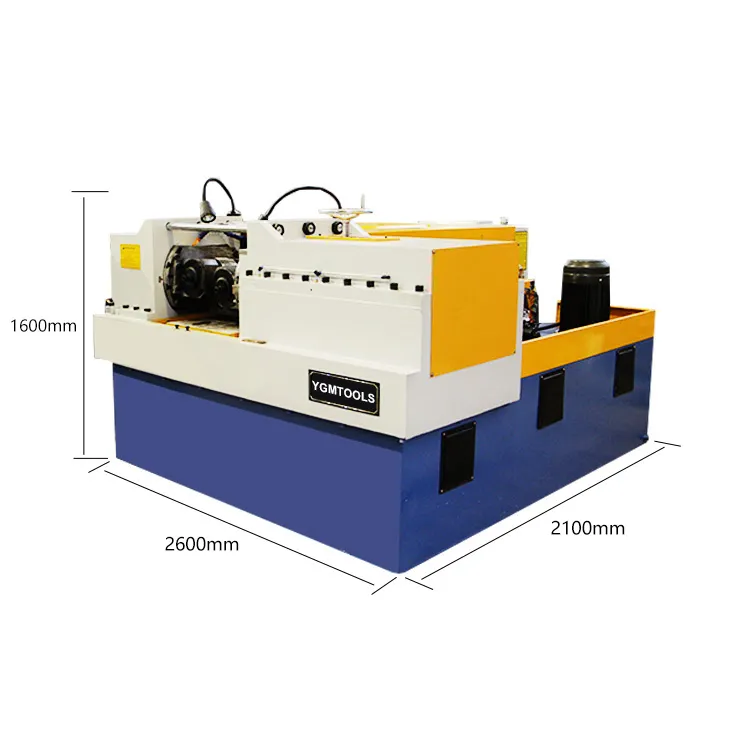

thread rolling machine company

The Evolution of Thread Rolling Machine Companies

In the ever-evolving landscape of manufacturing technologies, thread rolling machines have emerged as indispensable tools in the fastener and automotive industries. Companies specializing in thread rolling machines play a crucial role in the production of various components that require high precision and durability. This article delves into the significance, advancements, and future prospects of thread rolling machine companies.

Understanding Thread Rolling

Thread rolling is a cold forming process used to create external threads on cylindrical workpieces. Unlike traditional cutting methods, thread rolling enhances the mechanical properties of the material by aligning the grain structure, which results in parts that are both stronger and more resistant to wear. The process also generates less waste, making it an environmentally friendly option. Thread rolling machines can produce threads more quickly and with greater repeatability than conventional machining processes.

The Rise of Thread Rolling Machine Companies

The history of thread rolling machine companies dates back to the Industrial Revolution when the demand for precision-engineered components began to rise. Over the decades, manufacturers have evolved their machinery and techniques to adapt to the ever-increasing demands of industries such as automotive, aerospace, and electronics. Companies like Acme, H. B. McClure, and Tornos have established themselves as leaders in this sector, continually innovating to meet the needs of their customers.

Innovations in Technology

Modern thread rolling machines incorporate advanced technologies, such as CNC (Computer Numerical Control) and servo-driven systems. These innovations allow for greater accuracy and efficiency, reducing downtime and increasing production rates. The integration of automation and robotics has further transformed the operations of thread rolling machine companies, enabling them to streamline manufacturing processes and reduce labor costs.

Moreover, with the advent of Industry 4.0, many thread rolling machine companies are adopting smart technology to monitor and optimize production in real-time. Sensors and data analytics are increasingly being used to identify maintenance needs, predict failures, and enhance overall equipment effectiveness. This shift towards digital manufacturing not only improves operational efficiency but also empowers companies to offer better services and products to their customers.

thread rolling machine company

Meeting Industry Demands

As industries evolve, so do the requirements for fasteners and components. The automotive sector, for instance, is increasingly shifting towards electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These technologies require specialized fasteners that can withstand different loads and conditions. Thread rolling machine companies are rising to this challenge by developing machines capable of producing high-strength fasteners with complex geometries.

Furthermore, the aerospace industry demands components that meet stringent safety and performance standards. Thread rolling machines are designed to produce parts that comply with these regulations while also being lightweight and durable. As such, thread rolling machine manufacturers are continually conducting R&D to enhance their machine capabilities and ensure they can meet the industry's evolving challenges.

Future Prospects

Looking ahead, the future of thread rolling machine companies appears promising. As manufacturing becomes more globalized, the demand for high-quality, precision-engineered components will increase. This demand will drive innovation within the thread rolling sector, leading to the development of even more sophisticated machines that can cater to diverse applications.

Additionally, the push for sustainability in manufacturing will likely lead to further advancements in thread rolling technology. Companies that prioritize eco-friendly practices and develop machines that reduce waste and energy consumption will be well-positioned to succeed.

Conclusion

Thread rolling machine companies are at the forefront of manufacturing innovations, playing a critical role in various industries by producing high-quality, precision-engineered components. As technology continues to advance, these companies will adapt and evolve, meeting the ever-changing demands of the market. With a focus on efficiency, sustainability, and quality, the future of thread rolling machine companies is bright, promising improved manufacturing processes and innovative solutions for critical applications across the globe.