-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

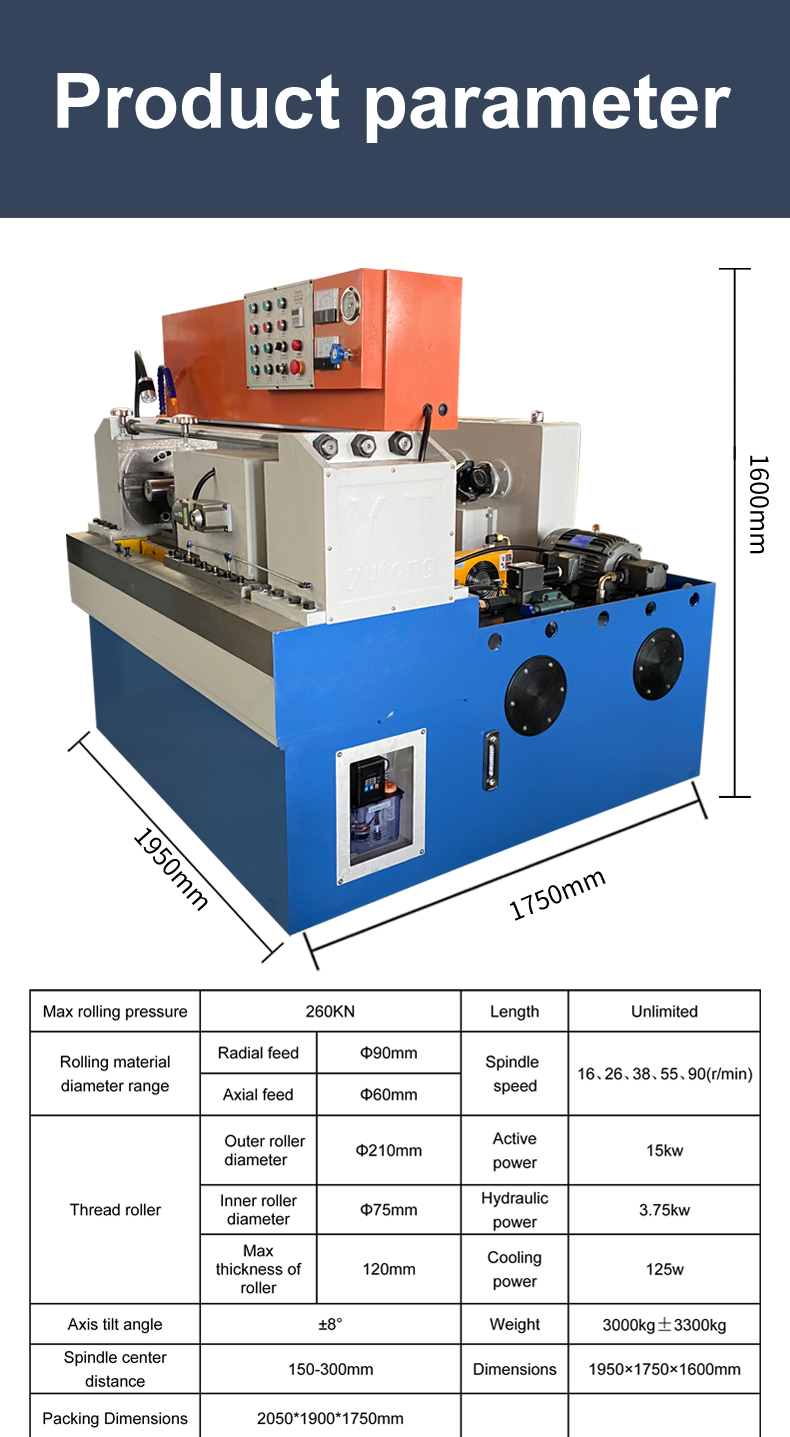

cheap bolt thread rolling machine

The Cost-Effective Solution Cheap Bolt Thread Rolling Machines

In today’s manufacturing landscape, the efficiency of production is paramount. Industries ranging from automotive to construction increasingly seek innovative solutions that can enhance productivity while reducing operational costs. One such innovation is the bolt thread rolling machine, particularly those available at a lower price point. These machines play a crucial role in the production of high-quality threaded components, essential for various applications.

Understanding Thread Rolling Technology

Thread rolling is a cold-forming process that creates threads on cylindrical parts, such as bolts and screws, through a series of rolls. This method not only enhances the strength of the threads but also improves surface finish, leading to improved performance in applications where durability and reliability are fundamental. The cold-working process minimizes waste and increases material utilization, making it an environmentally friendly option.

The Advantages of Cheap Bolt Thread Rolling Machines

Investing in affordable bolt thread rolling machines opens up several advantages for manufacturers. Firstly, these machines provide cost savings without compromising quality. By utilizing advanced manufacturing techniques, many suppliers have managed to offer reliable machines at a lower price, allowing small and medium-sized enterprises (SMEs) to access technology that was once reserved for larger corporations.

cheap bolt thread rolling machine

Additionally, cheap bolt thread rolling machines often incorporate user-friendly features, enabling quicker setup and easier operation

. This results in reduced training times for operators and allows companies to adapt to changing production demands with efficiency.Moreover, these machines typically require less maintenance than traditional threading methods. This reliability translates to lower operating costs over time, as manufacturers can allocate their resources more effectively and avoid prolonged downtimes.

Choosing the Right Machine

When selecting a cheap bolt thread rolling machine, companies should consider several factors. First, evaluate the machine’s capacity and the types of materials it can handle. Compatibility with existing production lines is also crucial to ensure seamless integration. Furthermore, researching the manufacturer's reputation and customer support services is vital, as these aspects greatly influence long-term satisfaction and machine performance.

Conclusion

In conclusion, cheap bolt thread rolling machines represent a compelling opportunity for manufacturers looking to enhance productivity while managing costs. By embracing this technology, businesses can not only improve the quality of their threaded components but also streamline operations, ultimately driving growth in an increasingly competitive market. As the industry continues to evolve, such cost-effective solutions will likely become standard practice in the manufacturing of fasteners and similar components.