-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

buy thread rolling machine working

Understanding the Working of a Thread Rolling Machine and Its Advantages in Manufacturing

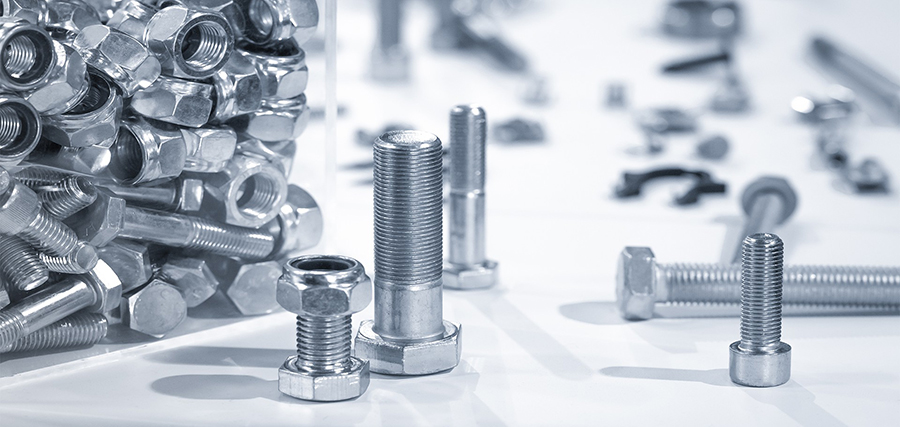

In the realm of manufacturing, the efficiency and precision of production processes play a crucial role in determining the quality and performance of the final products. One significant component in this process is the thread rolling machine, which specializes in producing threads on cylindrical parts. The technology has gained prominence due to its ability to create high-quality threads while enhancing production speed and reducing material waste. This article delves into the working principles of thread rolling machines, their advantages, and applications across various industries.

What is a Thread Rolling Machine?

A thread rolling machine is a specialized equipment used to create threads on metal workpieces. Unlike traditional machining methods that cut material to form threads, thread rolling employs a cold-forming process. This process involves the displacement of material rather than its removal, which leads to a denser and stronger thread. Thread rolling machines come in various types, including flat, cylindrical, and planetary machines, depending on the specific threading requirements.

Working Principles of Thread Rolling Machines

The operation of a thread rolling machine is centered around a few critical elements the workpiece, the dies, and the rolling mechanism. Here’s how it generally works

1. Setup and Alignment The first step involves securely clamping the metal workpiece, which is usually cylindrical, into the machine. Accurate alignment is essential to ensure that the threads produced are uniform and meet the specified dimensions.

2. Die Selection The machine uses two or more dies, which have the desired thread profile. These dies are designed to compress the workpiece as it is rolled between them. Depending on the machine type, the dies can either move toward each other or the workpiece can rotate against them.

3. Rolling Process When the machine is activated, the workpiece is rotated while the dies apply pressure on its surface. The material is deformed under this pressure, flowing into the shape of the dies. This cold-forming process not only creates threads but also enhances the physical properties of the material, such as tensile strength and fatigue resistance.

4. Finishing After the rolling process is complete, the workpiece may undergo additional finishing processes, such as cleaning or coating, to ensure optimal performance and corrosion resistance.

buy thread rolling machine working

Advantages of Using Thread Rolling Machines

The use of thread rolling machines presents numerous benefits in manufacturing

1. Increased Strength With cold-forming, the threads produced have better mechanical properties compared to cut threads. The compressive stress and flow of material create a denser structure, enhancing the overall strength and performance of the fasteners.

2. Cost Efficiency The thread rolling process results in minimal material waste, as it does not involve cutting away material. This efficiency translates to lower production costs and less scrap, benefiting manufacturers economically.

3. Higher Production Rates Thread rolling machines are capable of producing threads at a much faster rate than traditional cutting methods. This increased productivity is especially beneficial for high-volume manufacturing cases.

4. Improved Accuracy and Consistency The automated nature of thread rolling machines leads to higher precision and consistency in thread profiles. This uniformity reduces the risk of product failure and increases the reliability of the final products.

5. Versatility Thread rolling machines can be used on various materials, including steel, aluminum, and alloys. They can also produce multiple thread sizes and profiles, making them versatile for different applications.

Applications of Thread Rolling Machines

Thread rolling machines are employed across various industries, including automotive, aerospace, electronics, and construction. They are crucial for manufacturing screws, bolts, nuts, and other threaded components essential for assembling products reliably.

In conclusion, thread rolling machines are indispensable in modern manufacturing, providing a fast, cost-effective, and efficient solution for threading needs. By understanding their working principles and advantages, manufacturers can better leverage this technology to improve their production processes and product quality. As industries continue to evolve, the role of thread rolling machines is likely to expand, further solidifying their position in the manufacturing landscape.