-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

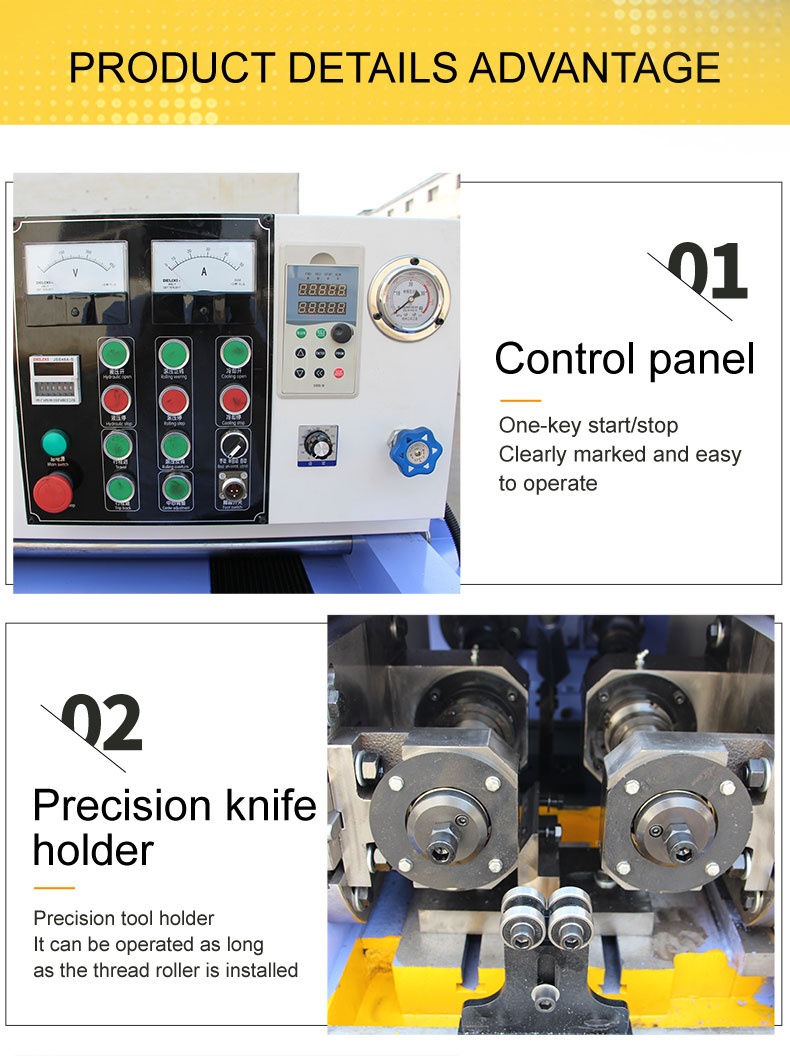

odm thread rolling tool

The Evolution and Benefits of ODM Thread Rolling Tools

In the manufacturing industry, precision and efficiency are paramount. One of the tools that have significantly improved these factors is the ODM thread rolling tool. Designed for high-speed production, these tools utilize a unique process to create threads that exceed traditional cutting methods in durability and accuracy. This article explores the evolution, mechanisms, and advantages of ODM thread rolling tools, highlighting their importance in modern manufacturing.

Historically, the process of thread formation involved cutting or machining, which often led to material wastage and required significant time investment. As technology advanced, the need for more efficient methods became evident. This led to the development of rolling techniques, where metal is deformed rather than cut to create threads. ODM (Original Design Manufacturing) thread rolling tools represent a significant advancement in this area, emphasizing quality and speed.

The Evolution and Benefits of ODM Thread Rolling Tools

One of the primary advantages of ODM thread rolling tools is their efficiency in production. The rolling process can produce threads significantly faster than conventional cutting methods. This increase in speed allows manufacturers to meet higher demands without compromising quality. Moreover, because less material is wasted during the rolling process, manufacturers can enjoy lower material costs and a reduced environmental footprint.

odm thread rolling tool

In addition to efficiency, ODM thread rolling tools offer superior dimensional accuracy. The nature of the rolling process ensures that threads are uniformly formed, which is critical for applications requiring precise tolerances. This accuracy reduces the need for secondary processes to correct imperfections, further saving time and reducing production costs.

Another benefit is the flexibility these tools offer. ODM thread rolling tools can be engineered for a variety of thread profiles and sizes, making them suitable for diverse applications across industries such as automotive, aerospace, and electronics. This adaptability allows manufacturers to streamline their operations by using a single tool for multiple products.

Furthermore, the durability of rolled threads cannot be overstated. Since rolling compacts the material and eliminates weak points associated with cutting, the threads produced tend to have higher tensile strength and resistance to wear. This characteristic makes them ideal for high-stress applications, prolonging the lifespan of the components thus manufactured.

In conclusion, ODM thread rolling tools have revolutionized the way industries approach thread manufacturing. Their superior efficiency, accuracy, and durability set them apart from traditional methods, addressing the evolving needs of modern engineering. As manufacturers continue to seek ways to enhance productivity and minimize costs, ODM thread rolling tools are likely to remain at the forefront of thread production technology. Embracing this advanced method can not only improve the quality of products but also contribute to the overall sustainability of manufacturing practices.