-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

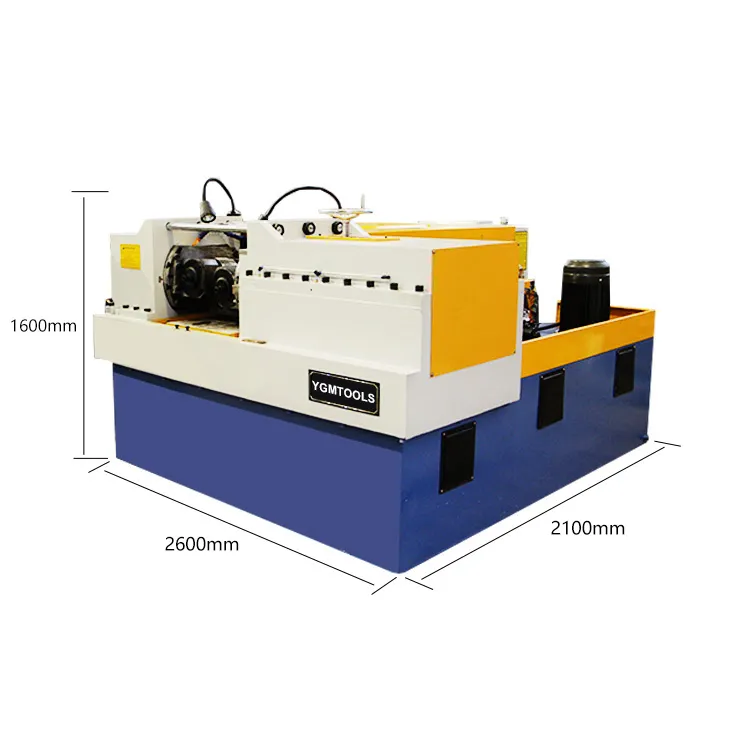

Factory for Automated Thread Rolling Machines and Equipment Production

The Rise of Automatic Thread Rolling Machines Innovations in Manufacturing

In the rapidly evolving landscape of manufacturing, the demand for efficiency and precision has led to significant advancements in machinery. One of the pivotal innovations in this sector is the automatic thread rolling machine. This technology has transformed how manufacturers create threaded products, enhancing productivity and ensuring the consistent quality of output. This article delves into the workings, benefits, and future of automatic thread rolling machines, spotlighting their role in modern factories.

Understanding Thread Rolling Machines

Thread rolling machines are specialized pieces of equipment used to create threads on metal rods or bars. The process, known as thread rolling, involves deforming the material to create threads instead of cutting them, which minimizes waste and improves the strength of the finished product. Historically, thread rolling was a manual, labor-intensive operation, limiting production speed and efficiency. However, automatic thread rolling machines have revolutionized this field by integrating advanced technology and automation.

These machines utilize rollers to apply pressure to a pre-formed blank, deforming the material to create the desired thread profile. The automatic nature of modern machines allows for continuous operations, reducing the time and labor required to produce high volumes of threaded products. With advanced controls, these machines can handle various materials and thread designs, making them versatile tools in any manufacturing setup.

Benefits of Automatic Thread Rolling Machines

1. Increased Productivity Automatic thread rolling machines operate at high speeds, significantly reducing the time required to produce threaded components. With the ability to run continuously and automatically adjust to different specifications, these machines can drastically increase output rates.

2. Consistent Quality The automation of the thread-rolling process minimizes human error, leading to greater consistency in product quality. Each threaded component produced is uniform in size and specifications, meeting stringent quality control standards.

3. Cost Efficiency Although the initial investment in an automatic thread rolling machine may be substantial, the long-term savings are significant. The reduction in labor costs, coupled with lower material waste and fewer rejected products, results in a higher return on investment.

automatic thread rolling machine factory

4. Flexibility and Adaptability Modern automatic thread rolling machines are designed to handle various sizes and types of materials. This adaptability makes them suitable for various industries, from automotive to aerospace, where specific threading requirements must be met.

5. Enhanced Safety Automation reduces the need for manual labor, which can often expose workers to risks associated with traditional manufacturing processes. By minimizing human intervention, the likelihood of workplace accidents decreases, promoting a safer working environment.

Applications in Various Industries

The versatility of automatic thread rolling machines allows their application across multiple sectors. In the automotive industry, they are used to produce bolts, connectors, and other vital components that require precise threading. In the aerospace sector, where safety and reliability are paramount, these machines ensure the high quality and durability of fasteners. Additionally, industries such as construction and electronics also rely heavily on thread rolling technology to produce a wide range of threaded parts.

The Future of Thread Rolling Technology

As technology continues to advance, the future of automatic thread rolling machines looks promising. The integration of smart manufacturing solutions, such as IoT and AI, is set to enhance machine capabilities even further. Predictive maintenance algorithms could minimize downtime, while real-time data analytics could optimize production processes.

Moreover, as industries move towards sustainability, automatic thread rolling machines will likely evolve to reduce energy consumption and material waste. Innovations in machine design and materials will ensure that these machines remain at the forefront of efficient manufacturing practices.

Conclusion

Automatic thread rolling machines represent a significant leap forward in the manufacturing sector, offering unparalleled efficiency and quality. As industries continue to embrace automation, these machines will play a crucial role in meeting the ever-increasing demands for precision and productivity. With ongoing innovations and improvements, the future of thread rolling technology is bright, promising to drive the manufacturing industry into a new era of excellence.