-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

best rebar thread rolling machine

Best Rebar Thread Rolling Machine A Comprehensive Guide

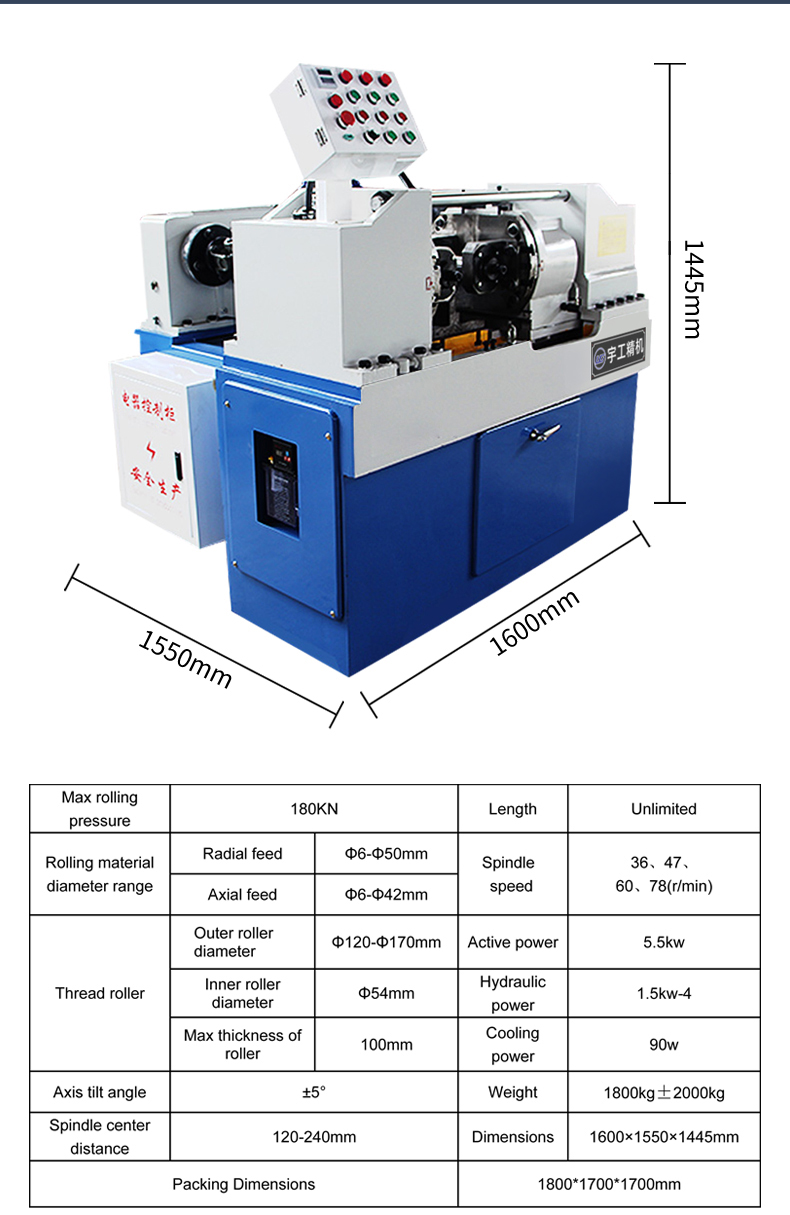

In the construction industry, the need for durability and strength in building materials is paramount. One essential material that plays a crucial role in reinforcing concrete structures is rebar (reinforcing bar). Given the growing demand for efficient and high-quality rebar processing, the use of advanced machinery is becoming increasingly important. Among the various tools available, the rebar thread rolling machine stands out as one of the most vital pieces of equipment for ensuring optimal performance and longevity in construction projects.

A rebar thread rolling machine is designed to create threads on rebar, allowing for a secure connection between rebar segments. This is particularly important in the construction of large structures, such as bridges, skyscrapers, and commercial buildings. By ensuring a tight connection, these machines significantly enhance the overall structural integrity of the project.

When selecting the best rebar thread rolling machine, several factors come into play. Firstly, the machine's capacity is crucial. Depending on the scale of the construction project, one must choose a machine that can handle the specific sizes and volumes of rebar required. Industrial-grade machines are capable of processing larger diameters and higher volumes, making them ideal for significant construction undertakings.

Secondly, the technology employed in the machinery is vital. Modern rebar thread rolling machines utilize advanced CNC (Computer Numerical Control) technology, which enhances precision and reduces human error. These machines can create consistent thread specifications, ensuring that each connection between rebar segments meets engineering standards. Additionally, automation of processes not only boosts productivity but also minimizes labor costs.

best rebar thread rolling machine

Safety features should not be overlooked when considering a rebar thread rolling machine. Operators must ensure the machinery includes protective guards and emergency stop functions to prevent accidents. Investing in a machine that adheres to safety regulations is not only essential for compliance but also helps protect the workforce.

Moreover, durability and maintenance are key considerations. A robust machine constructed from high-quality materials will withstand the rigors of a construction site, providing a long lifespan and better return on investment. Regular maintenance and support from the manufacturer can further enhance the machine's performance, ensuring it remains operational despite continuous use.

Another point to consider is the availability of spare parts and support services. A reputable manufacturer should provide readily available spare parts and efficient customer service. This is crucial to minimize downtime in case of repairs or maintenance, thus ensuring that construction schedules are adhered to.

In conclusion, selecting the best rebar thread rolling machine is a critical decision for construction professionals. By focusing on capacity, technology, safety, durability, and support, one can ensure that they invest in a reliable machine that meets the demands of modern construction. With the right equipment, construction companies can significantly enhance their productivity and the longevity of their projects.