-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

iul. . 11, 2024 07:55

Back to list

Service for 3% die thread rolling machine available now. Fast and reliable options.

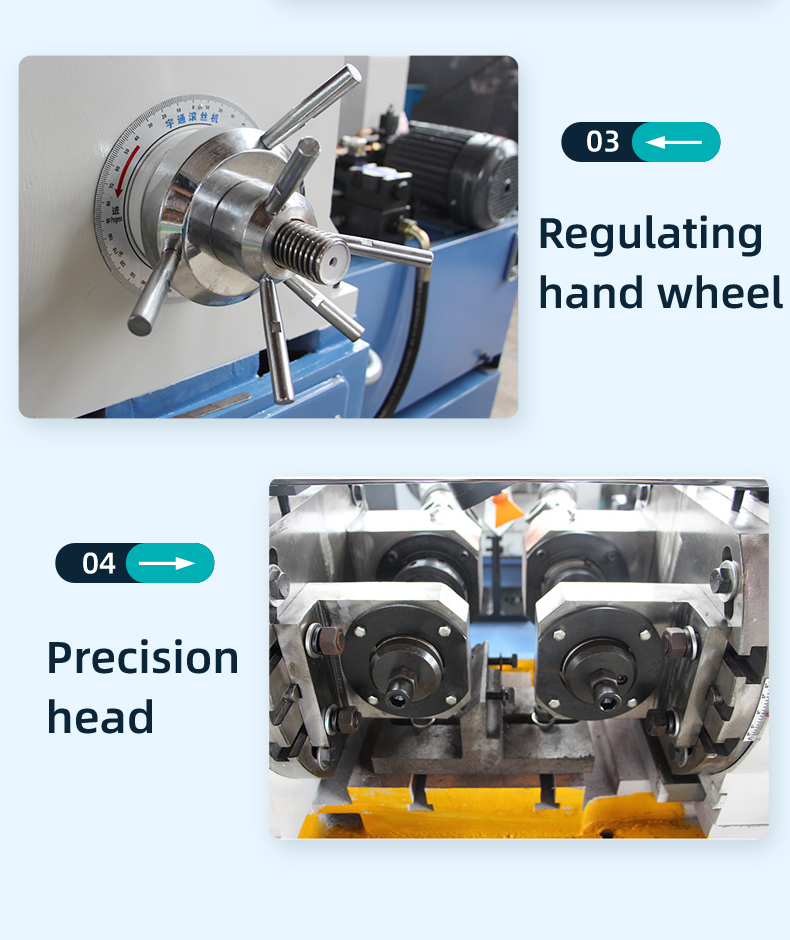

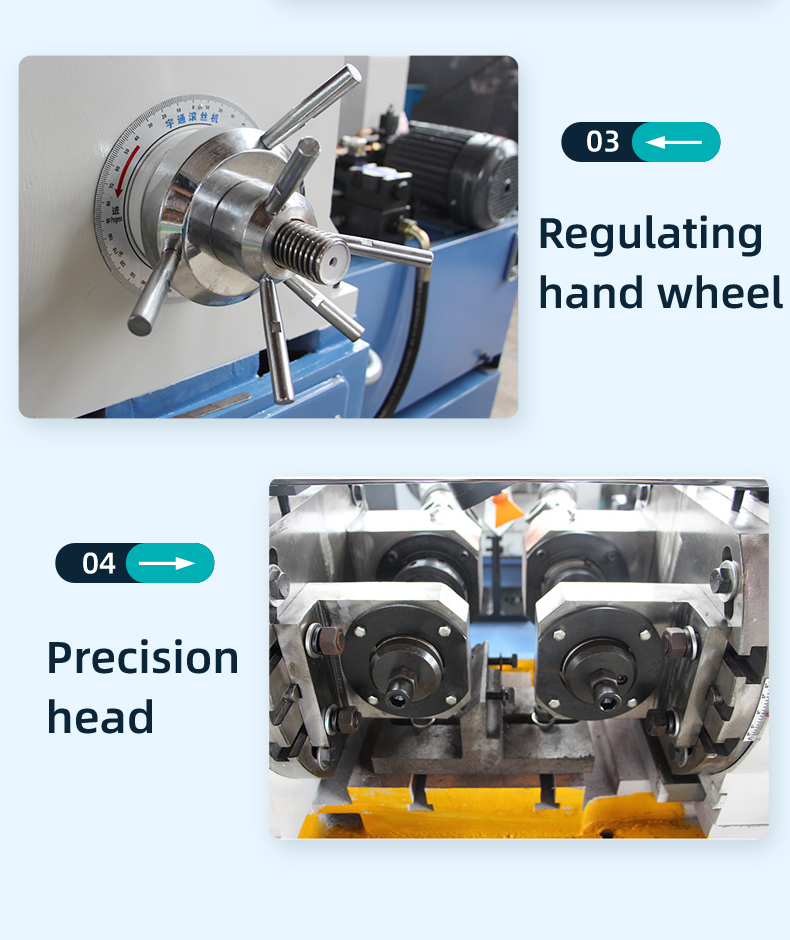

Thread rolling is a popular method used in the manufacturing industry to produce threads on various components. This process involves using a die or set of dies to deform a workpiece, typically made of metal, and create the desired thread profile. One of the key components in thread rolling is the thread rolling machine, specifically the die thread rolling machine.

A die thread rolling machine is designed to efficiently and accurately roll threads on different types of materials. These machines come in various sizes and configurations, depending on the specific application and requirements. One common type of die thread rolling machine is the 3% die thread rolling machine.

The 3% die thread rolling machine is known for its high precision and accuracy in producing threads with a 3% pitch diameter variation. This means that the threads created by this machine have consistent dimensions and are within the specified tolerances. This level of precision is crucial in industries where tight tolerances are required, such as automotive, aerospace, and construction.

One of the key advantages of using a 3% die thread rolling machine is the ability to produce threads quickly and efficiently. These machines are capable of rolling threads at a much faster rate than traditional methods like cutting or grinding

3 die thread rolling machine service. This not only saves time but also reduces production costs and improves overall productivity. Additionally, the threads produced by a 3% die thread rolling machine are typically stronger and more durable compared to threads created using other methods. This is because the rolling process cold-forms the material, resulting in a work-hardened surface that is resistant to wear and fatigue. This makes thread rolling an ideal choice for applications that require high-strength and reliable threads. In addition to strength and durability, threads produced by a 3% die thread rolling machine also have a smoother surface finish. This is due to the material being displaced rather than removed during the rolling process, resulting in clean and precise threads without any burrs or imperfections. This is especially important in applications where smooth mating surfaces are required, such as in hydraulic systems or precision machinery. Overall, the use of a 3% die thread rolling machine offers numerous advantages in terms of precision, speed, strength, and surface finish. This makes it an essential tool for manufacturers looking to produce high-quality threads efficiently and cost-effectively. Whether it's for automotive components, industrial machinery, or construction materials, the 3% die thread rolling machine is a reliable and versatile solution for all threading needs.

3 die thread rolling machine service. This not only saves time but also reduces production costs and improves overall productivity. Additionally, the threads produced by a 3% die thread rolling machine are typically stronger and more durable compared to threads created using other methods. This is because the rolling process cold-forms the material, resulting in a work-hardened surface that is resistant to wear and fatigue. This makes thread rolling an ideal choice for applications that require high-strength and reliable threads. In addition to strength and durability, threads produced by a 3% die thread rolling machine also have a smoother surface finish. This is due to the material being displaced rather than removed during the rolling process, resulting in clean and precise threads without any burrs or imperfections. This is especially important in applications where smooth mating surfaces are required, such as in hydraulic systems or precision machinery. Overall, the use of a 3% die thread rolling machine offers numerous advantages in terms of precision, speed, strength, and surface finish. This makes it an essential tool for manufacturers looking to produce high-quality threads efficiently and cost-effectively. Whether it's for automotive components, industrial machinery, or construction materials, the 3% die thread rolling machine is a reliable and versatile solution for all threading needs.

Share:

Latest news

Thread Rolling Manufacturer Cost Analysis

NewsAug.11,2025

Thread Rolling Equipment: Maintenance and Servicing Tips

NewsAug.11,2025

How to Maintain Thread Rolling Machines

NewsAug.11,2025

Bolt Rolling Machine Operation Manual

NewsAug.11,2025

Best Steel Bar Thread Rolling Machine Models

NewsAug.11,2025

Benefits of Reed Thread Rolling Machines

NewsAug.11,2025