-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

best roll thread machine

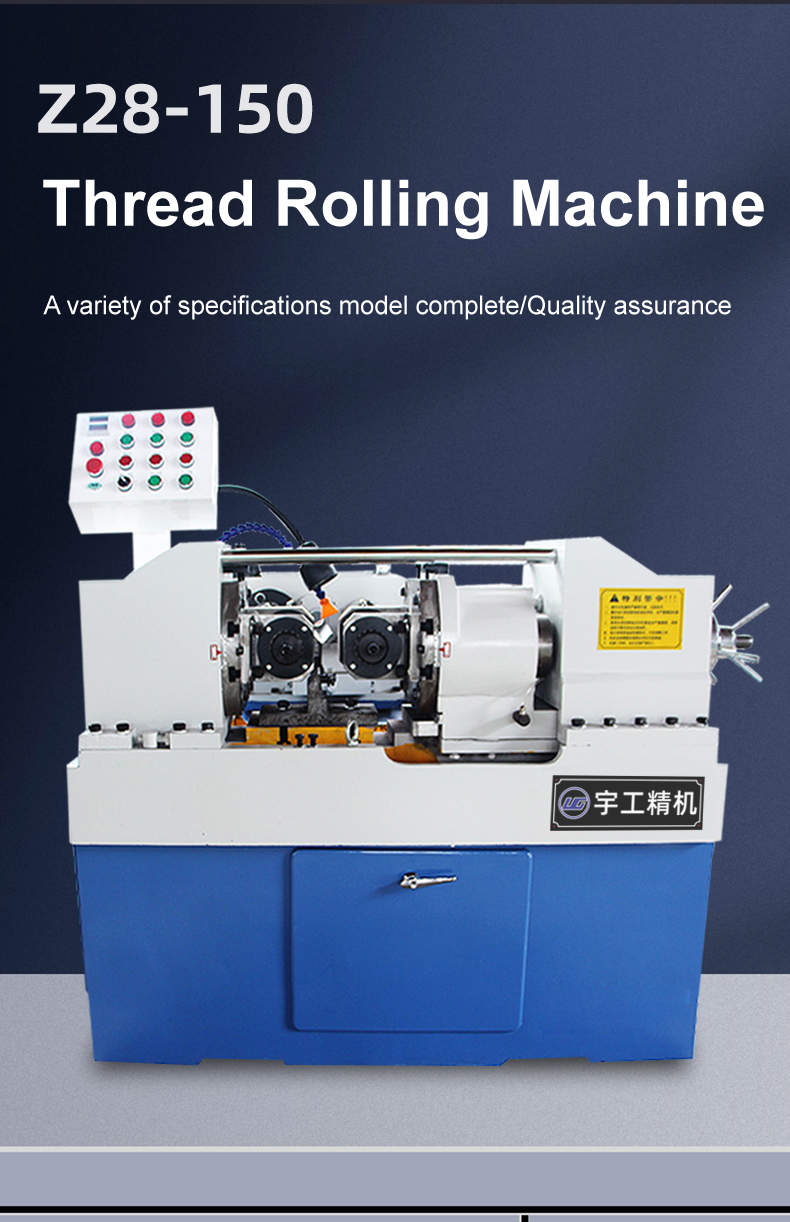

The Best Roll Thread Machine An Overview

In the fast-paced world of manufacturing, efficiency, precision, and versatility are paramount. Companies across various industries seek solutions that can enhance their production processes while maintaining high-quality standards. Among the many tools available, the roll thread machine stands out as a critical piece of equipment for producing high-strength threads on various materials. In this article, we’ll explore the features that make the best roll thread machines essential in modern production environments.

What is a Roll Thread Machine?

A roll thread machine is a specialized device used to create threads on metal, plastic, and other materials through a process known as thread rolling. This process displaces material rather than cutting it, allowing for greater strength and finer tolerances. The machine utilizes a rolling method, where two or more rollers are pressed against the workpiece to shape it into the desired thread form. The result is a robust thread that can withstand high stress and strain, making it ideal for applications in the automotive, aerospace, and construction industries.

Key Features of the Best Roll Thread Machines

1. Precision Engineering The best roll thread machines are designed with high precision in mind. Advanced CNC (Computer Numerical Control) technology ensures that each thread produced is consistent in diameter, pitch, and depth. This precision reduces waste and increases the operational efficiency of manufacturing processes.

2. Versatility Modern roll thread machines can handle various materials and thread sizes. This versatility allows manufacturers to switch between different production runs quickly and efficiently, adapting to market demands without significant downtime.

best roll thread machine

3. High Production Rates Time is money in the manufacturing sector. The best machines are engineered for high-speed operation, enabling them to produce a significant number of threaded parts in a short period. This capability is crucial for meeting tight deadlines and maintaining competitive advantage.

4. Robust Construction Durable construction is vital for any machine, especially in high-volume production environments. The best roll thread machines are built to withstand heavy use and adverse conditions, ensuring longevity and reliability.

5. User-Friendly Interface With the integration of digital technologies, modern roll thread machines feature intuitive user interfaces that simplify operation. Operators can easily program settings, monitor production, and perform maintenance tasks, contributing to efficient workflow and reduced error rates.

6. Cost-Effectiveness Although the initial investment for high-quality roll thread machines can be significant, they often lead to cost savings in the long run. The combination of reduced material waste, decreased labor costs, and increased production rates contributes to a lower overall cost of ownership.

Conclusion

In summary, the best roll thread machines are indispensable in today’s manufacturing landscape. Their ability to produce high-strength, precise threads quickly and efficiently makes them crucial for various industries. As technology continues to advance, these machines are expected to evolve further, incorporating smarter features that enhance automation and connectivity. Investing in a top-of-the-line roll thread machine can provide manufacturers with the edge they need to succeed in an increasingly competitive market. Embracing these innovations will undoubtedly lead to improved productivity and quality in manufacturing processes, setting the stage for future growth and success.