-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

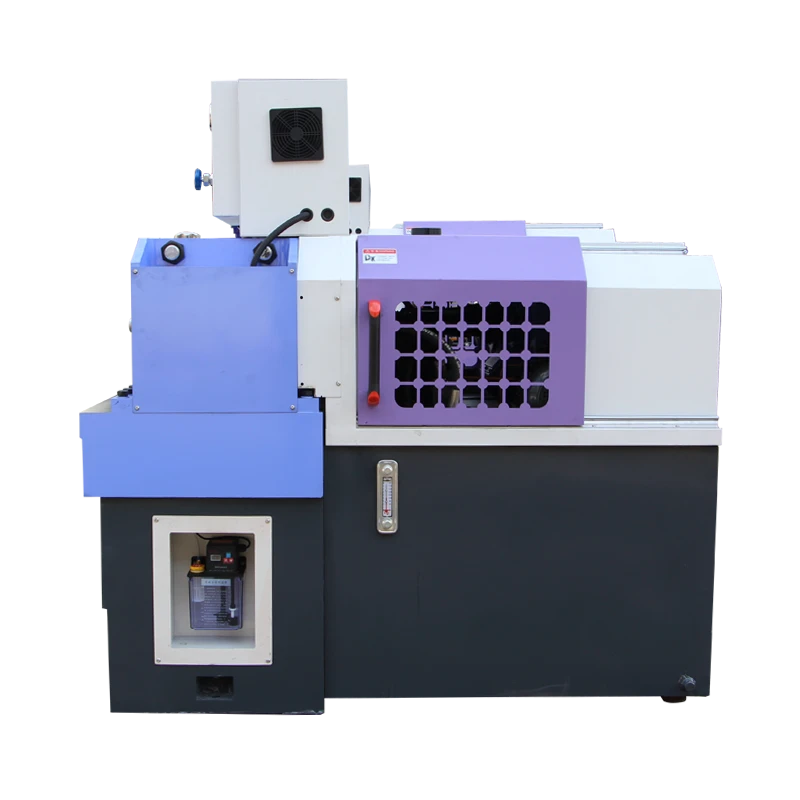

Different Types of Thread Rolling Machines and Their Exporters in the Industry

Types of Thread Rolling Machine Exporters

Thread rolling machines are essential in the manufacturing sector, particularly for producing threaded fasteners like bolts, screws, and nuts. These machines shape material into threads through a process called rolling, which is more efficient than cutting threads. As the demand for these threaded products increases globally, various exporters have emerged in the market, providing diverse types of thread rolling machines. This article will discuss the main types of thread rolling machine exporters and the machines they offer.

1. Manufacturers of Conventional Thread Rolling Machines

Conventional thread rolling machines are well-established in the market. These machines typically operate under the principle of flat or cylindrical rolling. Manufacturers specializing in these machines often focus on traditional techniques and have built a reputation for reliability and efficiency.

Exporters of conventional thread rolling machines usually offer various models that cater to different production needs. They often provide machines that can handle a range of materials, including steel, aluminum, and other alloys. These machines are suitable for small to medium production runs and are appreciated for their ease of operation and maintenance.

2. Exporters of CNC Thread Rolling Machines

With the advancement of technology, CNC (Computer Numerical Control) thread rolling machines have gained popularity. These machines offer higher precision and are capable of producing complex thread forms that are increasingly required in modern applications, including aerospace and automotive industries. Exporters of CNC thread rolling machines often highlight the benefits of automation, such as reduced labor costs and increased production speed.

These manufacturers usually provide training and technical support for their clients, ensuring that operators can fully utilize the sophisticated features of CNC machines. They often cater to both large-scale manufacturers and smaller firms looking to enhance their production capabilities.

3. Exporters of Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines use hydraulic pressure to shape materials into threads, resulting in higher force and smoother finishes. Exporters of hydraulic machines often target industries that require high-volume production due to the efficiency these machines provide.

types of thread rolling machine exporters

These exporters usually have a range of options, from small machines suitable for limited space to large-scale machines designed for massive productions. The versatility of hydraulic machines makes them suitable for various applications, and many exporters also offer customization options to meet specific customer requirements.

4. Specialty Thread Rolling Machine Exporters

Some exporters focus on specialty thread rolling machines designed for specific applications. This includes machines for rolling threads on unique shapes, such as bolts with custom head designs or screws designed for specialized industries. These exporters tend to have niche markets and excel in providing bespoke solutions.

Customers in specialized sectors often require more than just standard machines; they seek expertise and support in designing manufacturing processes that incorporate these custom machines. As a result, these exporters often work closely with clients to develop tailored solutions that meet their exact specifications.

5. Eco-Friendly Thread Rolling Machine Exporters

As the global industry pushes towards sustainability, some exporters are developing eco-friendly thread rolling machines. These machines minimize waste and energy consumption while maintaining productivity and quality. Manufacturers engaged in producing sustainable machines often emphasize their commitment to environmental responsibility, which is appealing to many businesses looking to enhance their green credentials.

Eco-friendly exporters typically invest in research and development to innovate new technologies that reduce their environmental impact. They often support their clients in achieving more sustainable production practices, thereby contributing to the overall effort to make manufacturing greener.

Conclusion

The landscape of thread rolling machine exporters is diverse, offering a wide range of products to meet the growing global demand for threaded components. From conventional and CNC machines to hydraulic options and specialty designs, businesses can find suitable solutions tailored to their needs. Additionally, the emergence of eco-friendly machines reflects the industry's commitment to sustainability, ensuring that as manufacturers evolve, they also consider their environmental footprint. As manufacturers explore these various types of exporters, they can enhance their productivity, efficiency, and sustainability in the ever-evolving marketplace of threaded products.