-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 31, 2025 01:36

Back to list

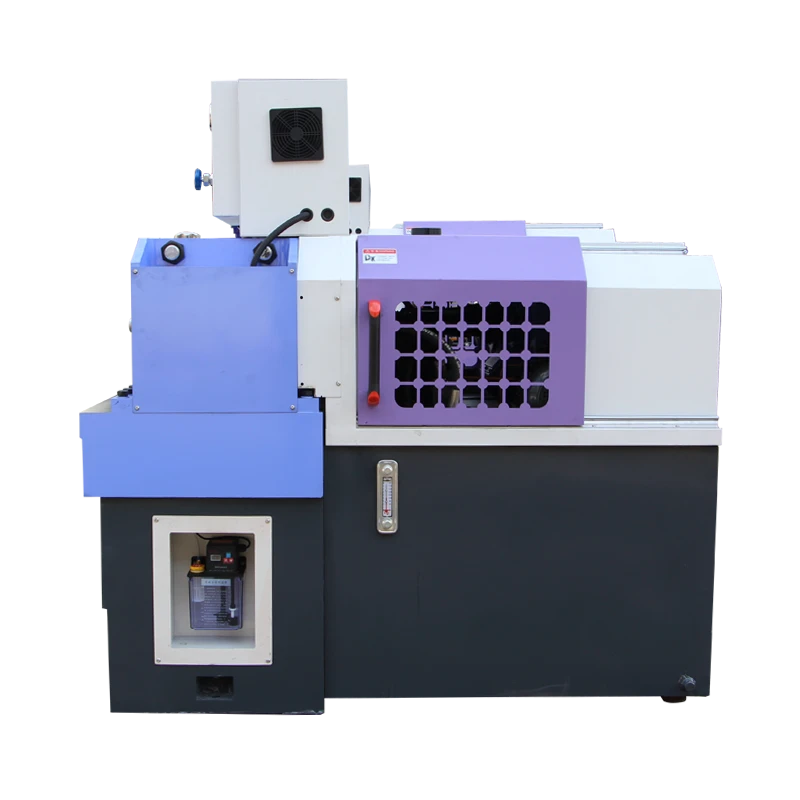

buy thread rolling machines for sale

In the rapidly evolving industrial landscape, manufacturing companies are constantly in search of efficient machinery that can enhance productivity and ensure consistent quality. Thread rolling machines are among the most sought-after equipment due to their ability to produce high-quality threads quickly and cost-effectively. For companies looking to invest in thread rolling machines for sale, understanding the nuances of these machines is crucial to making a well-informed purchasing decision.

Another consideration is the manufacturer's reputation and the after-sales service they provide. A reputable manufacturer typically offers comprehensive support, including installation, training, and maintenance services. This support can be invaluable, particularly for companies new to thread rolling, as it ensures that the machine operates efficiently from the outset. Additionally, manufacturers that offer extended warranties and readily available spare parts score higher on trustworthiness, as they demonstrate a commitment to their customers' long-term success. The cost-effectiveness of the machine is also a crucial consideration. While initial cost is an important factor, buyers should also consider the total cost of ownership. Machines that boast energy-efficient operations or require minimal consumables could contribute to long-term cost savings. An analysis of potential ROI can provide buyers with a clearer picture of the financial benefits and time frame for recouping their investment. To further enhance decision-making, it's advisable to seek insights from existing users of the machinery. User reviews and testimonials can provide invaluable first-hand accounts of the machine's performance in real-world scenarios. Networking with other industry professionals can also yield recommendations and cautionary tales that may not be apparent in product specifications or sales pitches. In conclusion, investing in the right thread rolling machine requires a careful evaluation of several factors, including material compatibility, technological features, build quality, manufacturer reputation, and cost-effectiveness. By prioritizing these critical aspects, buyers can make informed decisions that align with their operational demands and long-term business objectives. A well-chosen thread rolling machine can dramatically enhance production capabilities, ensuring consistently high-quality outputs and positioning companies for success in the competitive manufacturing landscape.

Another consideration is the manufacturer's reputation and the after-sales service they provide. A reputable manufacturer typically offers comprehensive support, including installation, training, and maintenance services. This support can be invaluable, particularly for companies new to thread rolling, as it ensures that the machine operates efficiently from the outset. Additionally, manufacturers that offer extended warranties and readily available spare parts score higher on trustworthiness, as they demonstrate a commitment to their customers' long-term success. The cost-effectiveness of the machine is also a crucial consideration. While initial cost is an important factor, buyers should also consider the total cost of ownership. Machines that boast energy-efficient operations or require minimal consumables could contribute to long-term cost savings. An analysis of potential ROI can provide buyers with a clearer picture of the financial benefits and time frame for recouping their investment. To further enhance decision-making, it's advisable to seek insights from existing users of the machinery. User reviews and testimonials can provide invaluable first-hand accounts of the machine's performance in real-world scenarios. Networking with other industry professionals can also yield recommendations and cautionary tales that may not be apparent in product specifications or sales pitches. In conclusion, investing in the right thread rolling machine requires a careful evaluation of several factors, including material compatibility, technological features, build quality, manufacturer reputation, and cost-effectiveness. By prioritizing these critical aspects, buyers can make informed decisions that align with their operational demands and long-term business objectives. A well-chosen thread rolling machine can dramatically enhance production capabilities, ensuring consistently high-quality outputs and positioning companies for success in the competitive manufacturing landscape.

Share:

Next:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025