-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

roll thread machine price suppliers

Understanding the Pricing of Roll Thread Machines Insights for Buyers

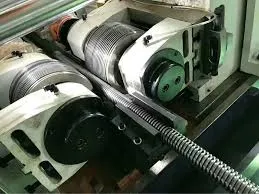

Roll thread machines are essential tools in the manufacturing of threaded fasteners and components, playing a vital role in various industries, including automotive, aerospace, and construction. As demand for precision-engineered parts continues to rise, understanding the pricing and suppliers of roll thread machines becomes increasingly important for manufacturers looking to optimize their production processes.

Market Overview

The market for roll thread machines is influenced by several factors, including the technology used, the complexity of the machine, and the level of automation. Prices can vary significantly depending on the manufacturer and the specific features of the machine. Basic models intended for small-scale operations may start at relatively low prices, while advanced machines with CNC capabilities and higher production efficiencies can reach rates exceeding hundreds of thousands of dollars.

Key Factors Affecting Pricing

1. Technology and Features The integration of advanced technology, such as CNC (Computer Numerical Control) systems, can lead to higher pricing due to increased flexibility, precision, and automation. Machines equipped with features like automatic feeders, enhanced safety protocols, and real-time monitoring systems will also tend to cost more.

2. Supplier Reputation The brand and reputation of the manufacturer play a crucial role in pricing. Established suppliers with a track record of reliability and customer support often charge a premium for their machines. Conversely, smaller or newer suppliers might offer competitive prices to attract customers.

roll thread machine price suppliers

3. Customization Custom-built machines tailored to meet specific needs will require a greater investment compared to standard models. Manufacturers looking for machines that can accommodate unique threading profiles or larger batch sizes should expect to pay a higher price for customized solutions.

4. Maintenance and Support Potential buyers should consider not just the initial purchase price but also the long-term costs associated with maintenance and support. Reliable after-sales service, availability of spare parts, and routine maintenance can significantly affect overall costs and should be included in the budgeting process.

Finding Reliable Suppliers

When searching for roll thread machine suppliers, it’s essential to conduct thorough research. Online marketplaces and trade shows provide valuable opportunities to explore various models and negotiate prices. Additionally, industry forums and manufacturer directories can offer insights into reputable suppliers.

Furthermore, companies should consider engaging with suppliers that offer comprehensive support packages. This can include training for operators, installation services, and ongoing technical support, which can enhance the return on investment by maximizing machine uptime and productivity.

Conclusion

In conclusion, the investment in roll thread machines requires careful consideration and analysis of various factors influencing pricing. By understanding the market dynamics, features, and supplier reputations, manufacturers can make informed decisions that align with their production needs and budget constraints. As the industry continues to evolve, staying updated on technological advancements will also be beneficial for manufacturers aiming to enhance their operational efficiency and product quality. Whether one is a small startup or a large production facility, strategic investments in reliable roll thread machines can pave the way for improved competitiveness in the marketplace.