-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

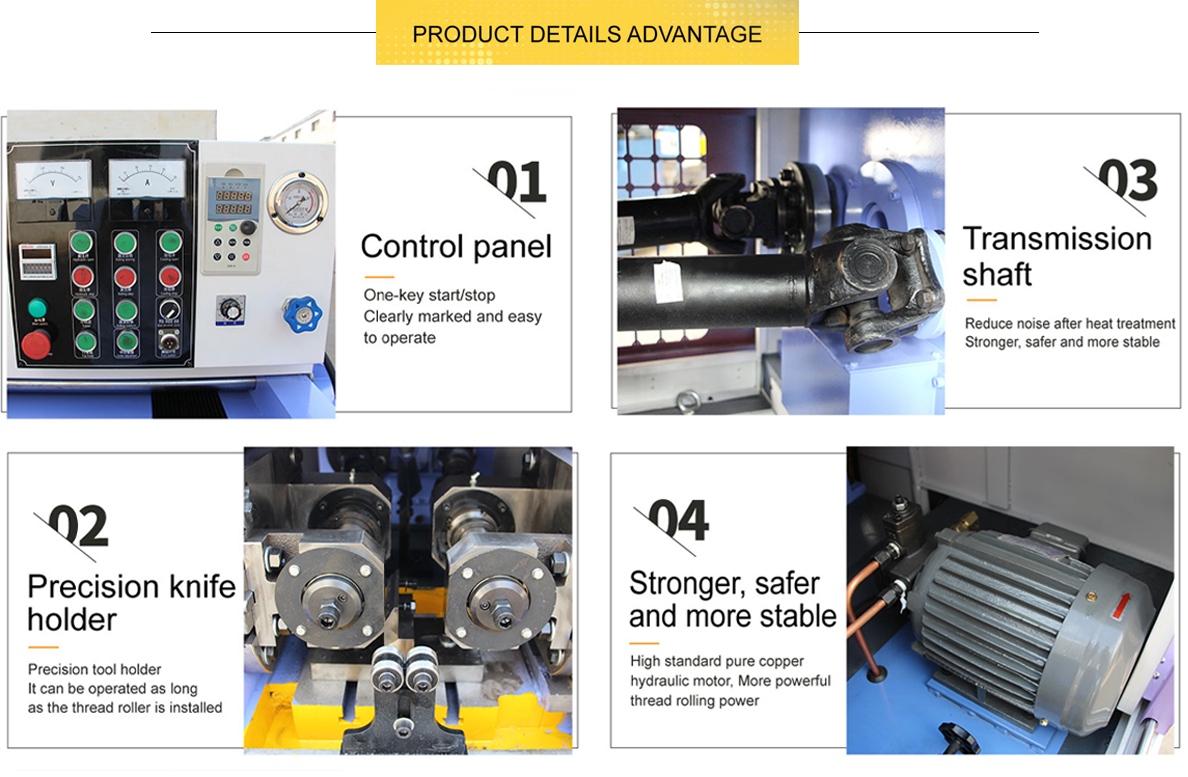

Wholesale Circular Thread Rolling Equipment for Efficient Production and High-Quality Results

The Evolution of Wholesale Circular Thread Rolling Machines

In the world of manufacturing, efficiency and precision are critical elements that dictate the success of a business. Among various machines that facilitate this, the wholesale circular thread rolling machine stands out as a significant innovation tailored for producing threaded fasteners with exceptional accuracy. This article explores the function, benefits, and advancements of circular thread rolling machines in the wholesale sector.

What is a Circular Thread Rolling Machine?

A circular thread rolling machine is a specialized piece of equipment used to create threads on cylindrical materials. Unlike traditional machining methods, such as cutting or grinding, thread rolling utilizes a cold-forming process. The material is pressed between two or more rotating dies, which impart the desired thread shape and dimensions. This method enhances the mechanical properties of the material while producing threads that are more uniform and precise.

Applications in Wholesale

In wholesale operations, especially those focusing on fasteners like screws, bolts, and nuts, the circular thread rolling machine plays an indispensable role. The machine can handle various materials, including steel, aluminum, and specialized alloys, making it versatile for numerous wholesale applications. By producing high volumes of threaded components quickly and efficiently, manufacturers can meet the demands of various industries, ranging from automotive to construction.

Key Advantages

1. Cost-Effectiveness One of the primary motivations for investing in circular thread rolling machines is the cost efficiency they offer. By using a cold-forming process, businesses can reduce material wastage significantly. Also, the production speed of rolling machines is often faster than traditional machining, translating into lower labor and operational costs.

2. Enhanced Quality and Durability The mechanical properties of rolled threads are superior to those created by cutting methods. Cold working increases the strength of the material, resulting in threaded components that can better withstand tension and shear forces. This enhanced durability is essential for applications where fasteners are subjected to dynamic loads.

wholesale circular thread rolling machine

3. Precision and Consistency Circular thread rolling machines are engineered for precision. They can achieve tolerances as low as a few microns, ensuring that every threaded piece meets specific standards. This level of consistency is crucial for wholesale operations that require large quantities of identical components.

4. Flexibility in Design These machines can be adjusted to produce various thread profiles and sizes, allowing manufacturers to cater to diverse client specifications. Whether it's standard threads or custom designs, wholesale circular thread rolling machines provide the flexibility needed to fulfill specific orders.

Technological Advancements

The evolution of circular thread rolling technology has led to significant improvements in performance and usability. Modern machines are equipped with advanced features like computer numerical control (CNC), allowing for automated adjustments and precise programming. This not only enhances the efficiency of the production process but also minimizes human error.

Additionally, advancements in materials and die technology have led to longer-lasting and more efficient machines. Manufacturers are now able to produce complex thread patterns more quickly than ever, eliminating the bottleneck often faced in traditional cutting processes.

Conclusion

In conclusion, the wholesale circular thread rolling machine is an essential tool in today’s manufacturing landscape. Its ability to produce high-quality, precise, and durable threaded components at a lower cost makes it a preferred choice for many businesses. With continuous technological advancements and a growing need for efficient manufacturing processes, the importance of circular thread rolling machines in the wholesale market is set to increase.

As industries continue to evolve and the demand for threaded fasteners rises, investing in advanced thread rolling technology becomes not just beneficial but essential for staying competitive. Whether you are a manufacturer or supplier, understanding and leveraging the capabilities of circular thread rolling machines will undoubtedly enhance your operations and drive your business forward.