-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

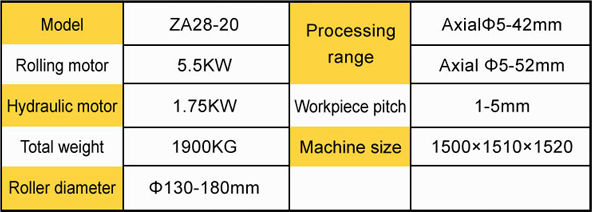

Compact Thread Rolling Machines for Precision Manufacturing Applications

The Evolution and Advantages of Mini Thread Rolling Machines

In the modern manufacturing landscape, efficiency and precision are paramount. One of the crucial elements that enhance production capability in the threading domain is the mini thread rolling machine. These compact machines revolutionize the threading process in various industries, from automotive to aerospace, ensuring that manufacturers maintain high standards of quality while optimizing their production lines.

What is a Mini Thread Rolling Machine?

A mini thread rolling machine is a specialized piece of equipment designed to create threads on cylindrical objects, typically fasteners like screws, bolts, and nuts. Unlike traditional machining methods that cut threads into a material, thread rolling utilizes a cold forming process. This technique involves pressing a workpiece between two specially designed dies which form the desired thread profile. The benefits of this method include improved material integrity, increased strength, and superior surface finish, all essential attributes for components subjected to high stress and wear.

The Advantages of Mini Thread Rolling Machines

1. Compact Size and Flexibility One of the most significant advantages of mini thread rolling machines is their compact size. This allows them to fit into smaller production spaces, making them ideal for small to medium-sized manufacturing operations. Despite their size, these machines do not compromise on performance, providing a balance between efficiency and footprint.

2. Increased Production Speed Mini thread rolling machines are designed for high-speed operations. They can produce a large volume of threaded components in a short amount of time, significantly improving productivity. This feature is especially beneficial for manufacturers who require a rapid turnaround for bulk orders.

mini thread rolling machine products

3. Cost Efficiency These machines typically consume less energy compared to larger, more complex systems. Additionally, the cold forming process of thread rolling minimizes material waste, as the metal is not removed but rather reformed. This can lead to significant cost savings over time, making mini thread rolling machines a smart investment for manufacturers.

4. Enhanced Thread Quality and Strength The cold forming process not only creates threads but also enhances the material properties. Components produced through thread rolling exhibit better tensile strength and fatigue resistance, which is crucial in industries where safety and reliability are paramount. The smooth surface finish achieved through this process can also reduce friction and wear, extending the life of the fasteners.

5. Versatility Mini thread rolling machines are versatile and can be used for creating various types of threads, including standard, metric, and custom profiles. This adaptability makes them suitable for a wide range of applications across different industries.

6. User-Friendly Operation Many modern mini thread rolling machines come equipped with advanced technology that simplifies their operation. User-friendly interfaces, automated controls, and programmable settings allow operators to quickly adjust parameters according to specific production needs, thus minimizing downtime and errors.

Conclusion

Mini thread rolling machines represent a significant advancement in the field of manufacturing. Their ability to produce high-quality threaded components efficiently and cost-effectively makes them an indispensable tool for many industries. As the demand for precision-engineered components continues to grow, investing in mini thread rolling machines could very well be the key to staying competitive in an increasingly demanding market. With ongoing technological advancements and innovations, the future of mini thread rolling machines looks promising, poised to further enhance manufacturing capabilities across the globe.