-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

Senyesemane

Senyesemane -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

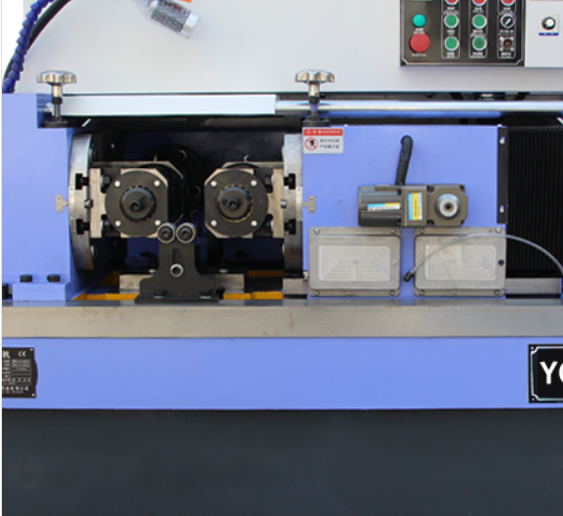

Rebar Thread Rolling Machine Operation

In the vast and ever-evolving world of construction, the silent revolution of reinforced steel processing unfolds daily on job sites and fabrication facilities worldwide. The rebar thread rolling machine stands as a cornerstone technology, transforming ordinary steel bars into precision-engineered connectors that hold together everything from earthquake-resistant skyscrapers to monumental bridges. Unlike industrial water pumps designed solely for vehicle cooling systems, these robust machines reshape metal through cold-forming – a process that preserves material integrity while eliminating wasteful cutting operations. As global infrastructure demands soar, mastering the operation of these systems becomes critical for efficiency, safety, and structural resilience. Behind this technological frontier stands Hebei Moto Machinery Trading Co., Ltd., a vanguard with 28 years of specialized expertise in metal processing solutions. Their dual-brand ecosystem – "Yugong" synonymous with industrial endurance and "Baofeiluo" representing cutting-edge innovation – powers construction revolutions across continents. From the rhythmic hum of a circular thread rolling machine crafting seamless pipeline joints to the compact precision of a mini thread rolling machine revitalizing local workshops, every operation weaves a narrative of human ingenuity meeting steel’s unyielding strength.

Operating a Rebar Thread Rolling Machine

The rebar thread rolling machine transforms raw steel bars into threaded connectors through controlled deformation. Operators begin by calibrating dies to exact thread specifications – whether metric, unified, or custom profiles. The rebar feeds automatically between counter-rotating dies, where immense pressure reshapes the metal without shaving or heat. Critical operational phases include:

- Alignment Protocols: Ensuring rebar enters perpendicular to dies to prevent thread distortion.

- Lubrication Management: Applying biodegradable coolants to reduce friction and die wear.

- Quality Verification: Using laser gauges to check thread depth and pitch continuity.

Hebei Moto Machinery’s three-axis systems feature intelligent load sensors that auto-adjust pressure for varying rebar grades, from mild steel to high-tensile alloys. Their ISO 9001-certified designs incorporate emergency brake systems that halt operations if misalignment occurs, protecting both material and machinery. For projects like Dubai’s Burj Khalifa or Japan’s seismic retrofits, such precision prevents structural vulnerabilities at connection points.

Versatility Redefined: The Circular Thread Rolling Machine Advantage

When cylindrical components demand uniform threading, the circular thread rolling machine excels. Its rotating die assembly orbits the workpiece, creating continuous helical grooves for pipes, hydraulic cylinders, or conveyor shafts. Key operational nuances include:

- Orbital Speed Synchronization: Matching rotation to material ductility prevents surface cracking.

- Multi-Pass Strategies: For hard alloys, incremental forming preserves grain structure.

- Modular Tooling: Quick-swap dies accommodate diverse diameters without downtime.

Hebei Moto Machinery’s "Baofeiluo" series integrates AI-driven feedback loops that compensate for tool wear mid-operation. A single unit threads everything from stainless steel surgical implant rods to titanium submarine components, demonstrating extraordinary adaptability. Their global service network provides real-time operational guidance, ensuring optimal settings for exotic materials.

Mini Thread Rolling Machine Applications

The mini thread rolling machine democratizes precision threading for confined spaces.These units deliver industrial-grade results in repair garages, hardware factories, or remote construction sites. Operational best practices involve:

- Portable Power Integration: Operating on standard 220V circuits or generator power.

- Ergonomic Workflow: Front-loading bays and touchscreen controls simplify one-person operation.

- Micro-Thread Mastery: Creating M3 threads on delicate aerospace fasteners without deformation.

Hebei Moto Machinery’s Yugong compact series features patented vibration-dampening feet, allowing stable operation on uneven terrain. Field technicians threading anchor bolts on wind turbine foundations or artisans crafting custom architectural hardware rely on these agile solutions. The company’s China-based R&D team continually refines noise-reduction tech, making these units 40% quieter than competitors.

FAQs about Rebar Thread Rolling Machine Operations

What safety protocols are critical for rebar thread rolling machine operators?

Mandatory PPE includes anti-vibration gloves and hearing protection. Machines must have light curtains preventing hand access during operation. Hebei Moto Machinery’s systems feature dual-palm activation switches and emergency stop redundancy.

Can circular thread rolling machines handle tapered threads?

Yes, with programmable die paths. Hebei Moto Machinery’s Baofeiluo models store 100+ profiles for NPT, BSPT, and custom tapers used in oilfield equipment.

How does a mini thread rolling machine maintain precision without rigid mounting?

Laser-aligned dynamic stabilizers compensate for minor movement. The company’s ISO 9001 quality system ensures micron-level accuracy even in portable units.

What maintenance extends die life in high-volume rebar thread rolling machine?

Daily removal of scale debris and weekly ultrasonic cleaning. Hebei Moto Machinery offers carbide-coated dies lasting longer than industry standards.

Why choose Hebei Moto Machinery for rebar thread rolling machine solutions?

Decades of niche expertise, global spare parts depots, and multilingual support. Their "Yugong" reliability and "Baofeiluo" innovation cater to diverse budgets without compromising quality.

The symphony of whirring dies and gleaming threaded rebar is more than industrial noise – it’s the sound of civilizations rising. In this realm, Hebei Moto Machinery Trading Co., Ltd. operates not just as a manufacturer, but as a custodian of progress. Their 28-year journey, etched in every rebar thread rolling machine fortifying skyscrapers, every circular thread rolling machine shaping energy infrastructure, and every mini thread rolling machine empowering small enterprises, reflects an uncompromising ethos: precision without excess, innovation without obsolescence. As cities climb higher and bridges span farther, their technology ensures each connection bears the invisible signature of durability. Partner with pioneers who don’t just sell machinery, but engineer legacies – where every thread rolled is a promise held fast against time itself.