-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Machines for Efficient Rebar Thread Rolling Processes in Construction Industry

The Importance of Rebar Thread Rolling Machines in Construction

In the ever-evolving world of construction, efficiency and precision play pivotal roles in project success. One of the crucial components that contribute to these factors is the rebar thread rolling machine. This machinery has revolutionized the way reinforcement bars (rebars) are prepared for various structural applications. In this article, we will explore the significance, functionality, and advantages of rebar thread rolling machines in the construction industry.

What is Rebar Thread Rolling?

Rebar, or reinforcement bar, is a crucial element used to enhance the tensile strength of concrete structures. Traditionally, the ends of rebars were welded or hooked together to ensure stability and strength. However, these methods could be time-consuming and less efficient. Enter the rebar thread rolling machine, designed specifically to create threaded ends on rebars. This innovation allows for a more secure and adaptable connection between rebars, fostering a more robust composite structure.

The thread rolling process involves cold working the rebar ends, creating durable threads that can easily be integrated with couplers. This method stands in stark contrast to welding, which can often weaken the rebar due to the intense heat used in the process.

How Does a Rebar Thread Rolling Machine Work?

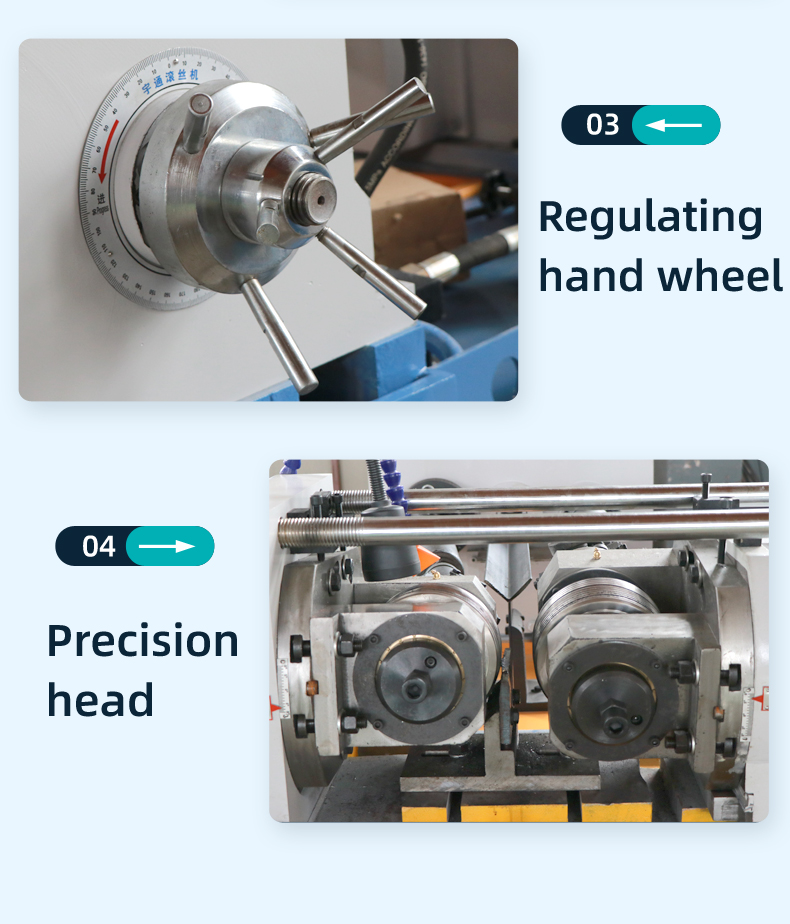

The rebar thread rolling machine operates using a straightforward but efficient mechanism. The machine typically consists of a set of rollers and a feeding mechanism. The rebar is fed into the machine, aligning it with the rollers that perform the threading operation.

As the rebar passes through the rollers, the machine applies pressure, creating external threads without removing any material from the bar. This cold deformation method not only preserves the rebar's integrity but also enhances its overall strength. The precision of the machine ensures that the threads are uniform and adhere to the specified dimensions, making it easier to connect the bars securely.

rebar thread rolling machine product

Advantages of Using Rebar Thread Rolling Machines

1. Efficiency One of the standout benefits of using a rebar thread rolling machine is the significant reduction in labor time. Manual methods can take a considerable amount of time, whereas a thread rolling machine can produce hundreds of threaded rebars in a fraction of that time. This efficiency translates to reduced costs and faster project timelines.

2. Quality and Consistency The use of a machine ensures a consistent quality of threads across all rebars. This uniformity is critical for maintaining structural integrity, as variations in thread size could lead to connection failures.

3. Enhanced Strength The cold working process not only preserves the rebar’s original properties but can also increase its yield strength, making it more suitable for demanding construction applications.

4. Versatility Rebar thread rolling machines are capable of handling various sizes and types of rebars, allowing construction businesses to adapt to different project requirements without needing multiple machines.

5. Reduced Waste Unlike traditional methods that may involve cutting or welding, the rolling process produces minimal waste. This efficiency is not only environmentally friendly but also cost-effective, as less material needs to be purchased.

Conclusion

In conclusion, rebar thread rolling machines are indispensable tools in modern construction. Their ability to enhance efficiency, maintain quality, and provide strength makes them a preferred choice for reinforcing concrete structures. As construction demands continue to grow, the importance of innovative machinery like rebar thread rolling machines will undoubtedly expand, shaping the future of building processes and ensuring that structures are safer and more reliable. Embracing such technology is essential for any construction business aiming to remain competitive in today’s fast-paced industry.