-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Mechanisms Behind Roll Thread Machinery and Its Applications

Understanding Roll Thread Machines A Comprehensive Overview

Roll thread machines are specialized pieces of equipment utilized in the manufacturing and metalworking industries for creating threads on cylindrical parts. These machines have gained popularity due to their efficiency, precision, and cost-effectiveness compared to traditional cutting methods. This article delves into the mechanics of roll thread machines, their applications, benefits, and considerations for manufacturers.

What is a Roll Thread Machine?

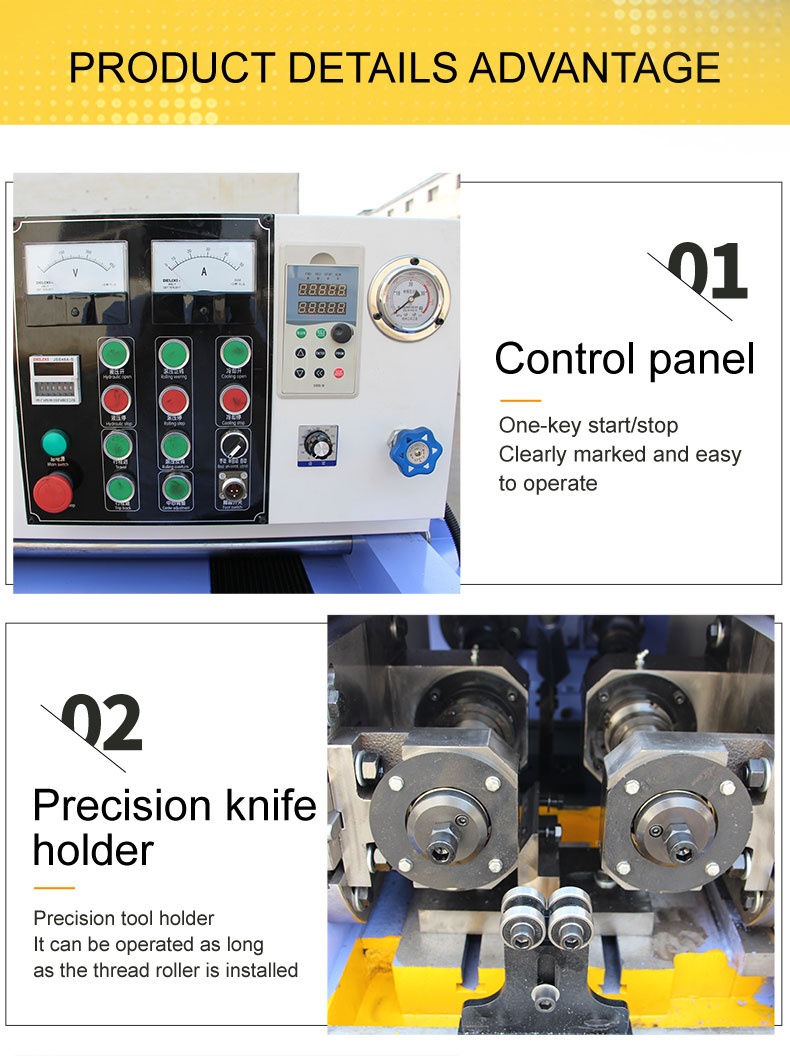

A roll thread machine is designed to form threads on metal rods, tubes, or other cylindrical components using a process called thread rolling. Unlike conventional methods that cut threads into the material, thread rolling displaces the metal to create a smooth and precise thread profile. This process typically uses two or three hardened rollers that exert pressure on the workpiece, forming threads without removing any material.

The thread rolling process generally involves three stages forming, rolling, and finishing. In the forming stage, the rollers begin to shape the material; during the rolling stage, the workpiece is turned to ensure uniform threads, and in the finishing stage, any extraneous materials or defects are removed to meet quality standards.

Applications of Roll Thread Machines

Roll thread machines are versatile and find applications across various industries. They are widely used in aerospace, automotive, manufacturing, and construction, where strong and reliable threaded parts are crucial. Common applications include

1. Fasteners Producing bolts, screws, and nuts that require precise threading for secure assembly. 2. Hydraulic Components Forming threads on hydraulic fittings and connectors essential in fluid systems. 3. Electronics Creating threaded components in electronic devices that ensure stability and connectivity. 4. Construction Manufacturing rebar and other structural components that require threading for robust construction.

roll thread machine

Benefits of Roll Thread Machines

The adoption of roll thread machines offers numerous benefits that appeal to manufacturers

1. Increased Strength of Threads The rolling process improves the grain structure of the metal, resulting in threads that are often stronger than those created through cutting. 2. Higher Production Rates Roll thread machines can produce threads much faster than traditional cutting methods, which leads to higher throughput and improved efficiency. 3. Reduced Material Waste Since the rolling process does not remove material, it generates minimal scrap, helping to conserve resources and reduce disposal costs. 4. Enhanced Surface Finish The formation of threads through rolling creates a smoother finish, reducing the need for additional machining or polishing processes.

Considerations for Manufacturers

While roll thread machines provide significant advantages, manufacturers must consider a few factors before implementation

1. Material Compatibility Not all materials are suitable for thread rolling. Manufacturers must ensure that the workpiece material can withstand the deformation process without fracturing. 2. Machine Setup Proper training and machine setup are essential to ensure accuracy in thread dimensions and profiles. This may require significant initial effort but pays off in consistent quality. 3. Maintenance Regular maintenance of the machines and rollers is crucial for prolonging their lifespan and ensuring optimal performance.

Conclusion

In summary, roll thread machines represent a modern evolution in manufacturing technology, providing efficient, cost-effective, and high-quality solutions for producing threaded components. As industries continue to evolve, the role of these machines in meeting the demands for precision and strength will only become more critical. Manufacturers looking to enhance their productivity and product quality would do well to consider incorporating roll thread machines into their operations.