-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

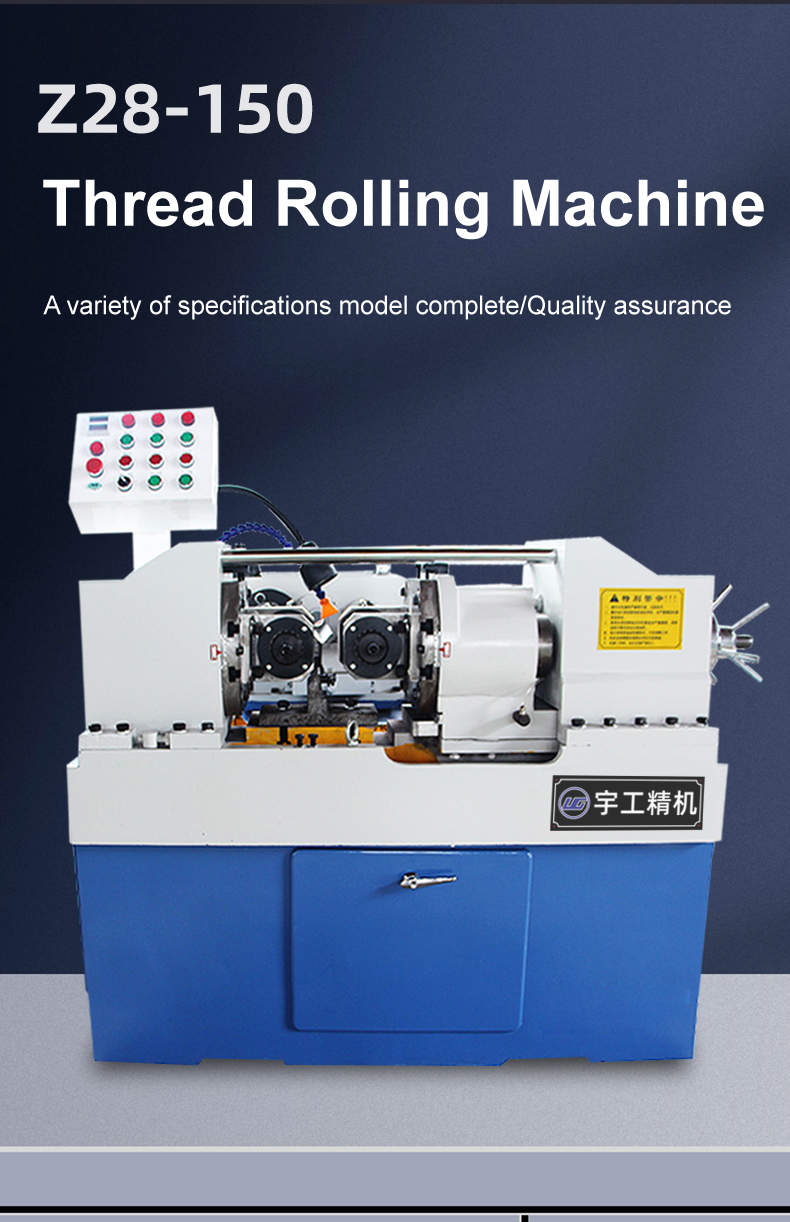

odm screw rolling machine

The Evolution of ODM Screw Rolling Machines

In the fast-paced world of manufacturing, the demand for precision and efficiency has led to the development of advanced machinery designed to meet rigorous industry standards. One significant innovation in this realm is the ODM screw rolling machine. These machines have revolutionized the production of screws, bolts, and other threaded fasteners, ensuring high-output manufacturing with enhanced quality and reduced production costs.

The Evolution of ODM Screw Rolling Machines

One of the standout features of ODM screw rolling machines is their ability to handle various types of materials, including carbon steel, alloy steel, and stainless steel. This versatility makes them suitable for a wide array of industries, from automotive to aerospace and construction. Furthermore, ODM machines can produce different types of fasteners, including hexagonal screws, lag bolts, and specialty screws tailored to specific applications.

odm screw rolling machine

Efficiency is a hallmark of ODM screw rolling machines. They can operate at high speeds, making them suitable for high-volume production runs. Automating the rolling process reduces labor costs and minimizes human error, leading to a higher output of consistent quality products. Additionally, many ODM machines are equipped with advanced control systems that allow for precise adjustment of the rolling parameters, ensuring that the final product meets exact specifications.

Another notable advantage of ODM screw rolling machines is their compact design. Unlike traditional machining processes, which often require significant floor space and complex setups, screw rolling machines are generally smaller and easier to configure. This space-saving design enables manufacturers to optimize their production lines, allowing for increased flexibility and adaptability to changing production demands.

Sustainability is another consideration driving the adoption of ODM screw rolling machines. The cold forming process generates less waste compared to machining methods, as it utilizes nearly the entire volume of raw material. This is particularly significant in today’s manufacturing landscape, where environmental responsibility is a growing concern. By minimizing waste and energy consumption, manufacturers can enhance their sustainability profiles and appeal to environmentally conscious consumers.

In conclusion, ODM screw rolling machines represent a significant advancement in the manufacturing of screws and other fasteners. With their efficiency, versatility, and eco-friendliness, they are poised to play a crucial role in the future of manufacturing. As industries continue to seek innovative solutions to meet the demands of modern production, ODM screw rolling machines will undoubtedly remain at the forefront of this evolution.