-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

ఆంగ్ల

ఆంగ్ల -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Rebar Thread Rolling Machine for Construction Sites

Hydraulic Thread Rolling Machine for Construction Applications

- Hydraulic thread rolling machineprovides superior power for processing construction-grade rebar

• The hydraulic system in hydraulic thread rolling machine ensures consistent pressure for quality threads

• Hydraulic thread rolling machine models feature adjustable pressure settings for different rebar diameters

• Oil-cooled systems in hydraulic thread rolling machine prevent overheating during continuous operation

• Portable hydraulic thread rolling machine versions are available for on-site construction use

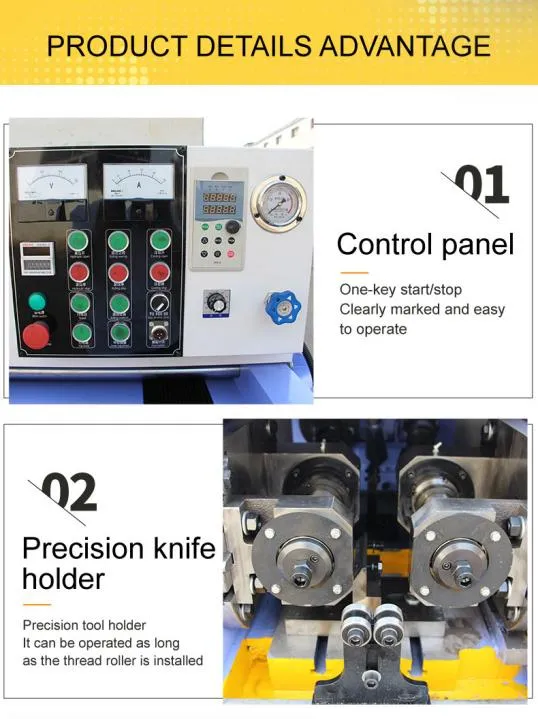

Rebar Thread Rolling Machine Key Features

- Rebar thread rolling machinespecializes in processing high-tensile construction steel bars

• Heavy-duty construction of rebar thread rolling machine handles diameters from 12mm to 40mm

• Rebar thread rolling machine produces threads that meet international construction standards

• Automatic feeding systems available for high-volume rebar thread rolling machine operations

• Reinforced frames on rebar thread rolling machine withstand rigorous construction site conditions

High Speed Thread Rolling Machine Productivity Benefits

- High speed thread rolling machinedramatically reduces threading time per rebar piece

• Advanced motor systems in high speed thread rolling machine maintain precision at rapid rates

• High speed thread rolling machine can process 30-50 rebars per minute in optimal conditions

• Energy-efficient design of high speed thread rolling machine lowers operational costs

• Vibration-dampening technology in high speed thread rolling machine ensures smooth operation

Product Specification

- 20-type series machines with variable frequency speed regulation

• Premium Schneider/Siemens electrical components

• P-class high-precision bearings for durability

• Ductile iron construction enhances machine lifespan

• Capable of processing various rebar grades and sizes

Packaging Details

- Heavy-duty plywood cases with reinforced corners

• Weather-resistant plastic film wrapping

• Fumigation-free materials for international shipping

• Custom crating available for large machines

• Clear handling instructions on all packages

Shipping Options

- LCL shipments via certified logistics partners

• FCL container loading by experienced technicians

• Door-to-door delivery services available

• Professional customs clearance assistance

• Real-time shipment tracking provided

Construction Site Advantages

- Rebar thread rolling machineenables on-site threading for just-in-time construction

• Hydraulic thread rolling machine models operate without external power sources

• High speed thread rolling machine reduces project timelines significantly

• All-weather operation capability for rebar thread rolling machine

• Minimal training required for construction crews

Hydraulic Thread Rolling Machine FAQS

Q: What are the key advantages of a hydraulic thread rolling machine?

A: A hydraulic thread rolling machine offers superior precision and consistency in thread formation due to its hydraulic system’s ability to deliver uniform pressure during the rolling process. This makes it ideal for high - strength applications such as automotive bolts or industrial fasteners where thread integrity is critical. Hydraulic systems also handle large - diameter workpieces better by generating higher force than mechanical or pneumatic alternatives. Additionally these machines feature adjustable pressure settings allowing operators to fine - tune the process for different materials from steel to aluminum without compromising thread quality. Their durability and low maintenance requirements contribute to long - term cost efficiency making them a staple in heavy - duty manufacturing environments.

Q: How does a rebar thread rolling machine enhance construction projects?

A: A rebar thread rolling machine revolutionizes construction by enabling reliable splicing of reinforcing bars essential for seismic - resistant structures. By cold - forming threads on rebar ends the machine creates joints that match or exceed the bar’s tensile strength eliminating the need for traditional lap joints that waste material and reduce structural integrity. This method is valuable for tall buildings bridges and infrastructure projects where rebar length must be extended without weakening the load path. The machine’s portability allows on - site threading minimizing transportation costs and delays. With precise thread pitch control it ensures compatibility with couplers meeting international standards for safety and durability in concrete construction.

Q: What factors determine the efficiency of a high speed thread rolling machine?

A: The efficiency of a high speed thread rolling machine depends on its rotational speed material hardness and die design. Higher RPMs reduce cycle times but must be balanced with the material’s ability to withstand friction and heat during rolling. Stainless steel may require lower speeds to prevent work - hardening while carbon steel can tolerate faster operations. Advanced machines integrate servo motors and digital controls to adjust speed in real - time optimizing productivity and thread quality. Automated feeding systems and quick - change die setups minimize downtime making high - speed machines perfect for mass production of screws bolts and other threaded components.

Q: Can a hydraulic thread rolling machine be used for non - metal materials?

A: While hydraulic thread rolling machines are designed for metals they can be adapted for certain non - metal materials with modifications. Dense plastics like nylon or acetal may accept rolled threads if hydraulic pressure is reduced to prevent deformation. Non - metals lack the ductility of metals so thread depth and pitch must be carefully calibrated to avoid cracking. Rubber or composite materials are generally unsuitable for traditional thread rolling due to their lack of structural integrity. Consult the machine manufacturer or perform material testing before attempting to roll threads on non - metal workpieces to ensure compatibility and safety.

Q: How does maintenance affect the performance of rebar thread rolling machines?

A: Regular maintenance is vital for rebar thread rolling machines to maintain precision and extend lifespan. Key tasks include cleaning die components to remove metal shavings inspecting hydraulic fluid levels for contamination and lubricating moving parts to prevent wear. Dull or damaged dies cause thread inconsistencies so replacing them early is essential. Calibrating the machine’s alignment ensures uniform thread formation especially when processing varying rebar diameters. Neglecting maintenance reduces thread quality increases energy consumption and causes costly breakdowns particularly in high - volume construction sites where downtime means significant delays. Following the manufacturer’s maintenance schedule preserves reliability and ensures safety compliance.

Hebei Moto Machinery provides professional-grade rebar thread rolling machine solutions for construction projects worldwide. Our hydraulic thread rolling machine models deliver reliable performance in tough job site conditions, while our high speed thread rolling machine options maximize productivity. Contact our technical team today to discuss your specific project requirements and discover how our threading solutions can streamline your construction operations. Visit our www.motetools.com for complete specifications and to request a personalized quote.