-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

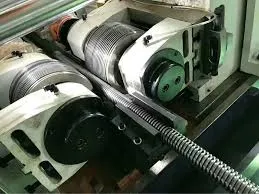

Varieties of Thread Rolling Machines and Their Applications in Manufacturing

Types of Thread Rolling Machines

Thread rolling is a cold forming process that produces threads on cylindrical workpieces. Unlike traditional cutting methods, this technique enhances the strength of the component while providing high precision and consistency. Thread rolling machines have gained popularity in various industries, such as automotive, aerospace, and manufacturing, due to their efficiency and ability to produce high-quality threads. In this article, we'll explore the different types of thread rolling machines, their mechanisms, and their applications.

1. Axial Thread Rolling Machines

Axial thread rolling machines are one of the most common types used in the industry. They operate by feeding cylindrical workpieces between two flat dies that have the reverse profile of the desired thread shape. As the dies rotate, they move axially along the length of the workpiece, gradually forming the thread. This type of machine is ideal for producing long threaded sections and is commonly used for bolts, screws, and other fasteners. Axial thread rolling is characterized by its ability to create intricate thread profiles with high dimensional accuracy.

2. Radial Thread Rolling Machines

Radial thread rolling machines, on the other hand, utilize a different approach. In this method, the workpiece is rotated while two or more rollers apply radial pressure to the surface. The rollers, which have a specific thread profile, move in a circular motion around the workpiece, causing the material to flow and form threads. This technique is often used for shorter lengths of material and produces threads with a larger diameter. Radial rolling is particularly effective for applications where greater strength is required, as it induces compressive stresses in the thread.

3. Multi-Die Thread Rolling Machines

types of thread rolling machine

Multi-die thread rolling machines incorporate multiple dies and rollers in the process, allowing for the simultaneous formation of multiple threads. This setup can significantly increase production rates and is especially beneficial for high-volume manufacturing operations. By utilizing multiple dies, manufacturers can produce various thread sizes and profiles in one cycle, making this type of machine highly versatile. Multi-die machines are commonly used in industries where large quantities of threaded components are needed, such as automotive and electronics.

4. CNC Thread Rolling Machines

With the advent of technology, CNC (Computer Numerical Control) thread rolling machines have transformed the thread rolling process. These machines utilize computer programming to manage the rolling operation, allowing for precise control over the speed, pressure, and movement of the dies and rollers. CNC technology enhances the accuracy of thread production, reduces setup time, and allows for easy adjustments to accommodate different thread specifications. This adaptability makes CNC thread rolling machines an excellent choice for industries needing quick changes in production runs.

5. Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines use hydraulic cylinders to apply force to the rollers, enhancing the efficiency of the process. The hydraulic system allows for easy adjustment of pressure, making it suitable for various materials and thread profiles. These machines are often more compact and require less maintenance than traditional mechanical systems, making them an attractive choice for small to medium-sized production facilities.

Conclusion

Thread rolling machines are vital tools in modern manufacturing, offering a range of capabilities to produce high-quality threaded components. Understanding the different types of thread rolling machines—axial, radial, multi-die, CNC, and hydraulic—enables manufacturers to select the right equipment for their specific needs. As technology continues to advance, we can expect further improvements in the precision, efficiency, and versatility of thread rolling machines, making them indispensable in the quest for high-performance threaded products in various industries.