-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

wholesale hydraulic thread rolling machine

Understanding Wholesale Hydraulic Thread Rolling Machines

In the world of manufacturing and industrial processes, efficiency and precision are key elements that can dictate the success of a business. Among the various machinery designed to support these manufacturing needs, hydraulic thread rolling machines play a significant role, especially in producing threaded products, such as bolts, screws, and other fasteners. This article explores the wholesale market for hydraulic thread rolling machines, their functionality, advantages, and key considerations for businesses interested in procurement.

What is a Hydraulic Thread Rolling Machine?

A hydraulic thread rolling machine is a specialized piece of equipment used to create threads on metal parts. Unlike traditional cutting methods, which remove material to form threads, rolling machines deform the material under high pressure to produce threads. This not only helps maintain the integrity of the material but also enhances the strength of the finished product.

Hydraulic machines use fluid power to generate force, making them highly efficient for mass production of threaded parts. They are designed to accommodate different materials and shapes, offering versatility in manufacturing processes.

Advantages of Using Hydraulic Thread Rolling Machines

1. Higher Strength The rolling process enhances the physical properties of the material, resulting in stronger threads. This is primarily due to the cold working effect, which aligns the grain structure of the material.

2. Cost-Efficiency Hydraulic thread rolling machines can produce threads faster than traditional cutting methods, significantly reducing labor costs and production time. Moreover, less material waste is generated, contributing to lower overall production costs.

3. Consistency and Precision These machines excel in creating uniform threads across large production runs. This consistency is crucial, particularly in industries where safety and reliability are paramount, such as automotive and aerospace.

4. Diverse Applications Hydraulic thread rolling machines can be used for a variety of materials, including steel, aluminum, and brass. Their adaptability makes them suitable for a wide range of applications, from small machine parts to large structural components.

wholesale hydraulic thread rolling machine

The Wholesale Market for Hydraulic Thread Rolling Machines

The wholesale market for hydraulic thread rolling machines is growing, driven by increasing demand for threaded components in various industries. A surge in manufacturing activities in sectors such as automotive, construction, and electronics has further propelled the need for efficient thread-forming technologies.

When considering a wholesale purchase of hydraulic thread rolling machines, buyers should evaluate several factors

1. Supplier Reputation Partnering with a reputable supplier is essential. A well-established supplier typically offers high-quality machines, reliable customer service, and comprehensive warranties.

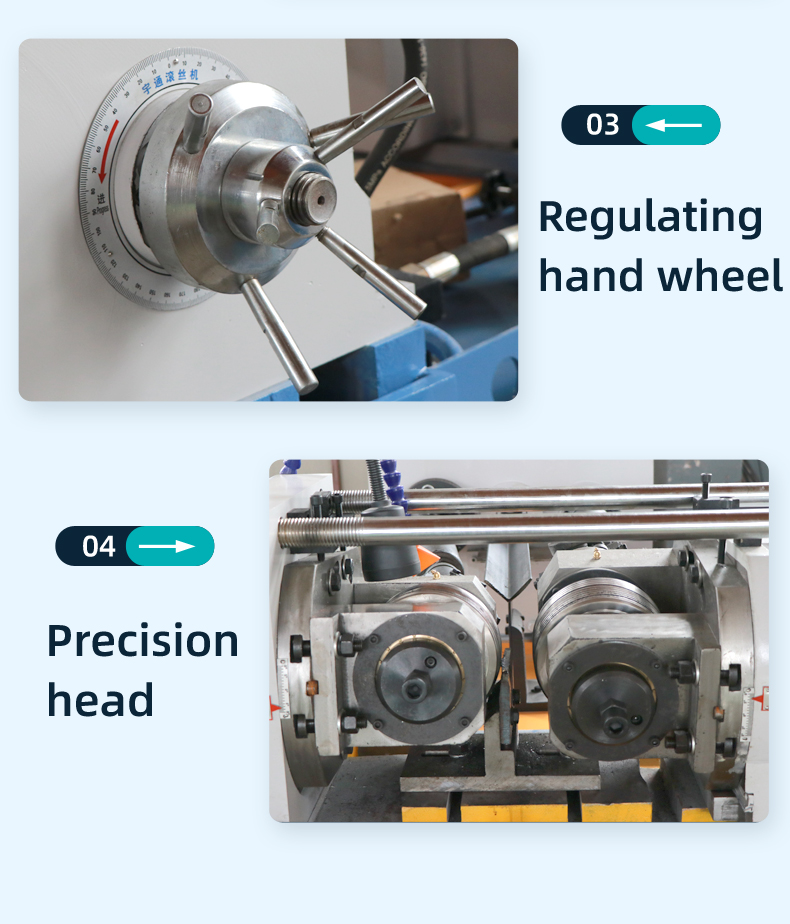

2. Specifications and Features Different machines come with varying specifications, including size, capacity, and technology features. It is crucial to select a machine that aligns with your production needs.

3. Customization Some manufacturers offer customization options to adapt machines for specific production requirements. Custom features might include adjustable speeds, additional tooling options, or modifications that enhance operation efficiency.

4. Maintenance and Support Regular maintenance is vital for the longevity of hydraulic machines. Buyers should inquire about the availability of technical support and spare parts to ensure that their machines can be serviced quickly and efficiently.

5. Cost Considerations While wholesale prices can offer discounts compared to retail, it’s important to balance cost with quality and functionality. A lower initial investment might lead to higher costs in the long run if the machine lacks efficiency or incurs higher maintenance costs.

Conclusion

As the demand for high-quality threaded products continues to rise, the wholesale market for hydraulic thread rolling machines becomes increasingly significant. These machines offer advantages in terms of strength, precision, and cost-effectiveness, making them an essential tool in modern manufacturing. For businesses looking to invest in hydraulic thread rolling machines, attention to supplier reputation, machine specifications, and support services can aid in making informed purchasing decisions. By understanding the benefits and considerations related to these machines, companies can enhance their manufacturing capabilities and maintain a competitive edge in their respective markets.