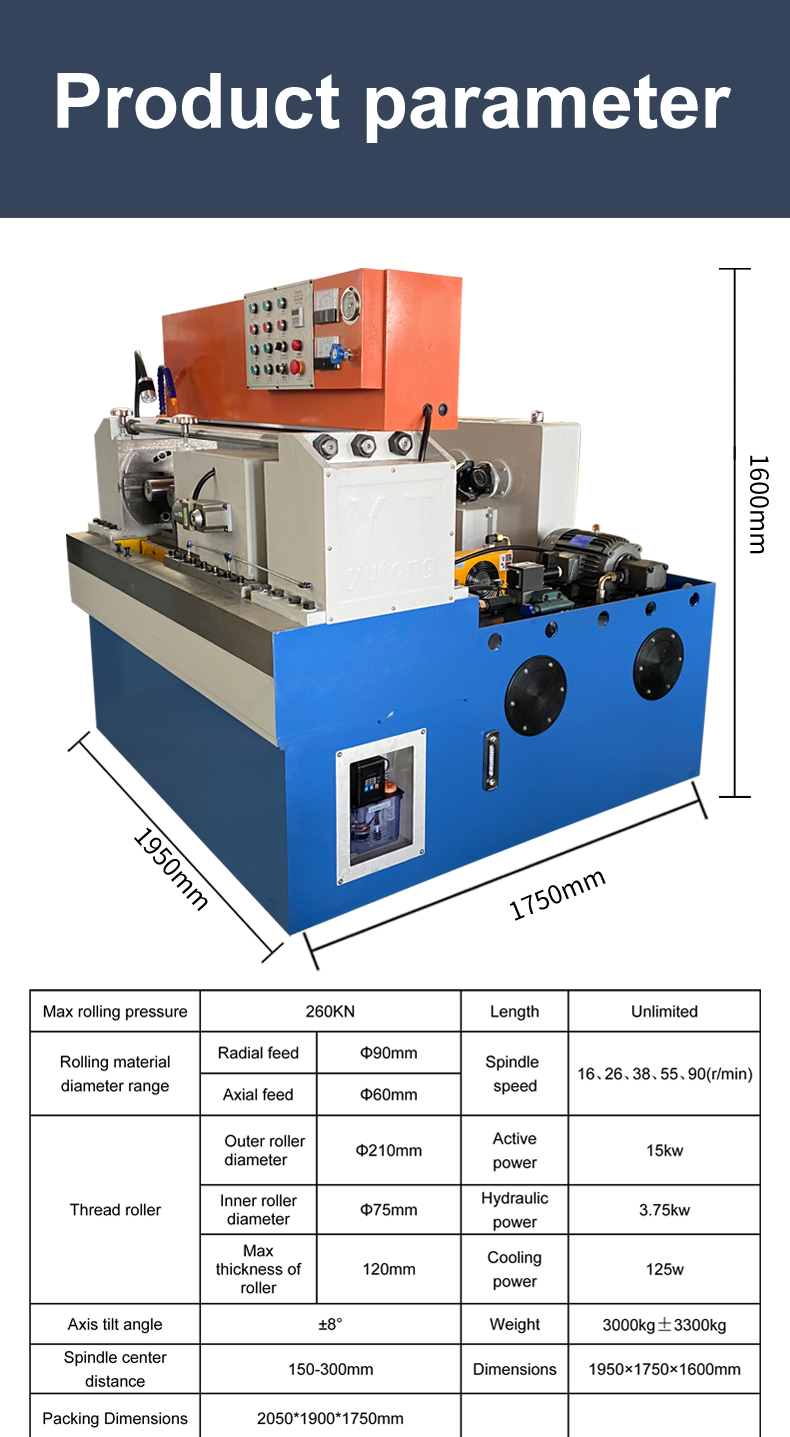

odm automatic thread rolling machine

The Evolution and Benefits of ODM Automatic Thread Rolling Machines

In the fast-paced world of manufacturing, efficiency and precision are paramount. Among the cutting-edge technologies that have revolutionized the production process is the ODM (Original Design Manufacturer) automatic thread rolling machine. This innovative equipment has transformed how threaded components are produced, offering significant advantages over traditional methods.

Understanding Thread Rolling

Thread rolling is a cold forming process used to create threads on various materials, primarily metallic components. Unlike traditional machining, which removes material to create threads, thread rolling displaces the material to form the desired shape. This process not only improves the mechanical properties of the threads but also enhances their surface finish. The result is stronger and more durable threads that can withstand higher levels of stress and wear.

The Role of ODM in the Industry

ODM manufacturers design and produce machinery tailored to the specific needs of their clients. An ODM automatic thread rolling machine is engineered to meet high standards of performance, efficiency, and customization. These machines integrate advanced technology and innovative designs to streamline the production process. By automating thread rolling, ODM machines minimize human intervention, reduce errors, and ensure consistency in the production of threaded components.

Benefits of Using ODM Automatic Thread Rolling Machines

odm automatic thread rolling machine

1. Increased Efficiency One of the most significant advantages of using ODM automatic thread rolling machines is their ability to operate at higher speeds. Automation allows for continuous production with minimal downtime, resulting in increased output and reduced lead times.

2. Precision Engineering ODM machines are designed with advanced CNC (Computer Numerical Control) technology, ensuring high precision in the rolling process. This level of accuracy guarantees that the threads produced meet the exact specifications required by clients, which is crucial in industries such as automotive and aerospace.

3. Cost-Effectiveness While the initial investment in an ODM automatic thread rolling machine may be higher than traditional methods, the long-term savings are substantial. Reduced material waste, increased production rates, and lower labor costs contribute to significant savings, making it a cost-effective solution for manufacturers.

4. Enhanced Durability The cold forming process of thread rolling produces threads with improved density and strength. As a result, the finished products exhibit superior resistance to fatigue and wear, extending their lifespan and reducing the need for replacements.

5. Flexibility and Customization ODM manufacturers often offer customizable machines that can be tailored to specific production needs. This flexibility allows businesses to adapt quickly to market demands and changes, making it easier to produce various threaded components.

Conclusion

As industries continue to evolve and the demand for high-quality, precision-engineered products grows, ODM automatic thread rolling machines stand out as a cornerstone of modern manufacturing. The benefits of increased efficiency, precision, cost-effectiveness, durability, and customization are driving their adoption across various sectors. By embracing this advanced technology, manufacturers can enhance their productivity and maintain a competitive edge in an increasingly global marketplace. In an era where every advantage matters, the ODM automatic thread rolling machine is a critical investment for those looking to thrive in the dynamic world of manufacturing.