-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine price list supplier

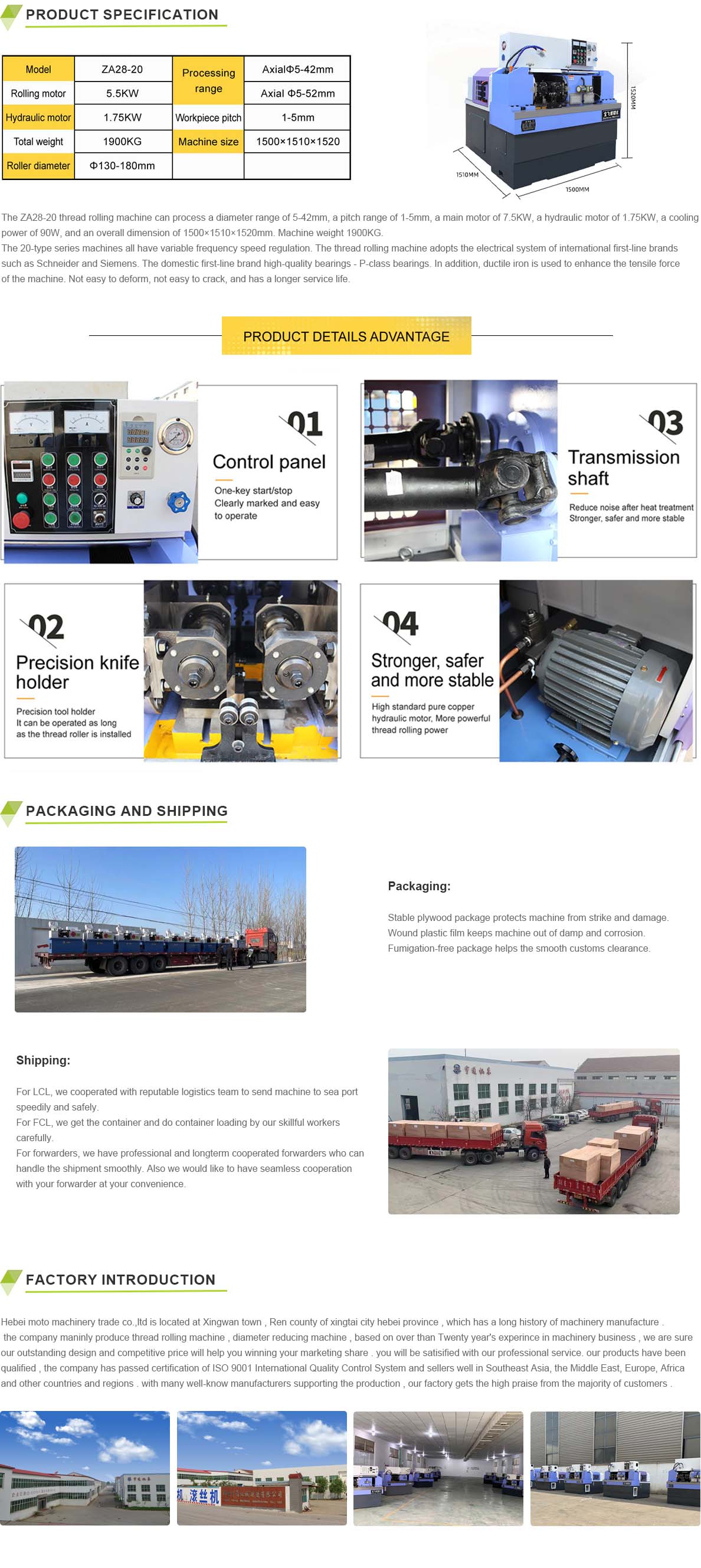

Understanding the Pricing of Thread Rolling Machines A Guide for Buyers

In the competitive landscape of manufacturing, thread rolling machines are essential for producing high-quality threaded fasteners. These machines enhance production efficiency and ensure precision in the threading process. However, the price of thread rolling machines can vary significantly based on several factors. For prospective buyers, understanding the pricing structure and what to consider when analyzing a supplier's price list is crucial.

Factors Influencing the Price of Thread Rolling Machines

1. Type of Machine The type of thread rolling machine plays a significant role in pricing. There are various types, including flat, cylindrical, and planetary rolling machines. Each type serves different applications and comes with unique features that affect cost. For example, a planetary thread rolling machine, which provides superior threading capabilities, typically costs more than a basic flat rolling machine.

2. Capacity and Specifications The production capacity and specific features of a machine also influence its price. Machines designed for high-volume production or equipped with advanced technology, such as CNC (Computer Numerical Control) systems, tend to be more expensive. Buyers should assess their production needs to determine the appropriate specifications that match their budget.

3. Brand Reputation Established brands often come with a higher price tag due to their reputation for reliability and quality. However, investing in a reputable brand can lead to better long-term performance and less downtime, potentially offsetting the initial cost.

4. Material and Build Quality The materials used in constructing the machine can significantly impact durability and performance. Machines built with high-quality materials may have higher upfront costs but can provide better longevity and reduced maintenance expenses.

thread rolling machine price list supplier

5. Supplier Location and Import Duties The geographic location of the supplier can also affect pricing. Local suppliers may offer lower costs due to reduced shipping and handling fees. On the other hand, importing machines from international suppliers can incur additional costs due to tariffs and duties.

6. After-Sales Support and Warranty When comparing prices, it's essential to consider after-sales support and warranty offerings. A machine might appear cheaper initially, but if it lacks proper support or has a short warranty period, it could lead to higher long-term costs.

Creating a Supplier Price List

When evaluating suppliers, a well-structured price list should include several key elements

- Base Price The cost of the machine itself, before any additional features or options. - Customizations Costs associated with any custom features or accessories that enhance the machine's functionality. - Shipping Costs Clear information regarding shipping fees and delivery times. - Warranty and Service Details about warranty coverage and available maintenance services. - Optional Training Costs for operator training or installation assistance, if available.

Conclusion

Investing in a thread rolling machine is a significant decision for manufacturers, impacting productivity and operational efficiency. By understanding the factors that influence pricing and carefully analyzing supplier price lists, buyers can make informed decisions that align with their business goals. Ultimately, choosing the right thread rolling machine involves balancing cost with quality and performance, ensuring that the investment yields sustainable returns in the long run.