-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

فېۋرال . 11, 2025 16:57

Back to list

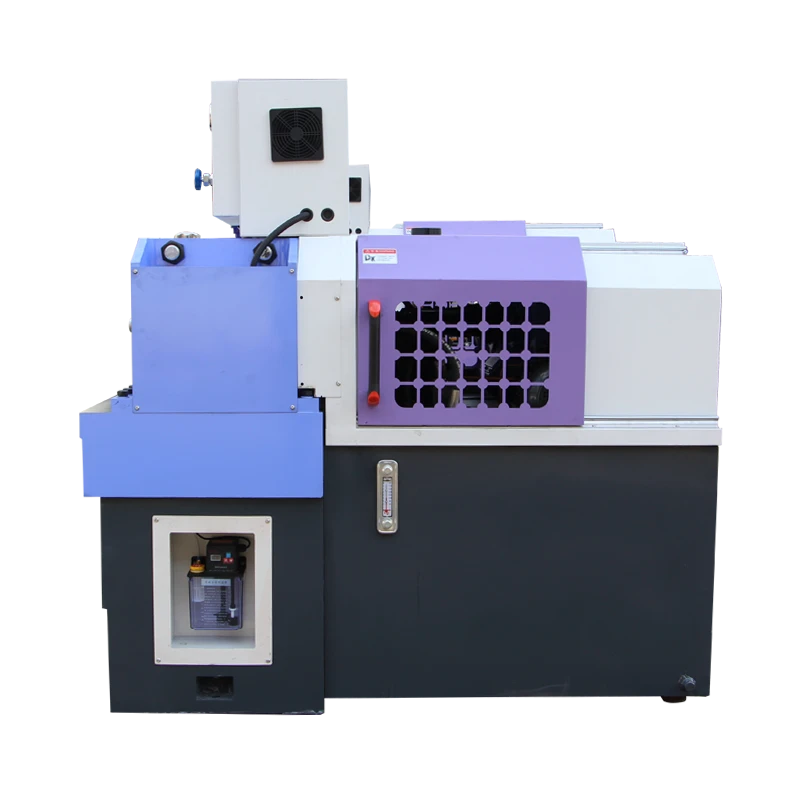

thread rolling machine flat die pricelist

When considering the competitive landscape of metal processing, the efficiency and precision of thread rolling machines play a pivotal role. This specialized equipment, especially those utilizing flat dies, offer unparalleled advantages in manufacturing high-volume threaded components. However, the cost factor remains a critical consideration for businesses seeking to optimize production while maintaining quality. This article delves into the practical experiences, professional insights, authoritative evaluations, and trustworthy recommendations concerning thread rolling machines, focusing on pricing dynamics.

Market demand further affects pricing. In periods of high demand, prices tend to surge due to increased competition for materials and components critical for machine assembly. Conversely, during market slowdowns, manufacturers may offer competitive pricing or financing options to stimulate purchases. Industry experts highlight the importance of total cost of ownership (TCO) rather than just the initial price tag. TCO encompasses all expenses, including maintenance, repairs, energy consumption, and lifespan of the machine. Opting for a slightly more expensive machine with lower TCO can prove beneficial in the long run, ensuring consistent operation without unforeseen expenditures. Authoritative assessments often recommend engaging with manufacturers or local distributors to explore pricing packages that might include training, installation, or extended support contracts. These added benefits enhance the value proposition, offering peace of mind alongside the equipment purchase. Finally, trustworthiness in selecting the right machine for your business involves not only evaluating the machine's specifications and price but also examining user reviews and case studies. Real-world testimonials provide reliable insights into performance, durability, and customer support experiences, which are invaluable for making a well-rounded decision. In conclusion, acquiring a thread rolling machine with flat dies involves a meticulous evaluation of various factors that affect pricing. A balanced approach that considers not just the upfront cost but also the long-term benefits and potential savings can significantly impact a business's manufacturing efficiency and product quality. Engage with knowledgeable industry professionals, rigorously assess your specific operational requirements, and make a purchase decision that aligns with your strategic goals.

Market demand further affects pricing. In periods of high demand, prices tend to surge due to increased competition for materials and components critical for machine assembly. Conversely, during market slowdowns, manufacturers may offer competitive pricing or financing options to stimulate purchases. Industry experts highlight the importance of total cost of ownership (TCO) rather than just the initial price tag. TCO encompasses all expenses, including maintenance, repairs, energy consumption, and lifespan of the machine. Opting for a slightly more expensive machine with lower TCO can prove beneficial in the long run, ensuring consistent operation without unforeseen expenditures. Authoritative assessments often recommend engaging with manufacturers or local distributors to explore pricing packages that might include training, installation, or extended support contracts. These added benefits enhance the value proposition, offering peace of mind alongside the equipment purchase. Finally, trustworthiness in selecting the right machine for your business involves not only evaluating the machine's specifications and price but also examining user reviews and case studies. Real-world testimonials provide reliable insights into performance, durability, and customer support experiences, which are invaluable for making a well-rounded decision. In conclusion, acquiring a thread rolling machine with flat dies involves a meticulous evaluation of various factors that affect pricing. A balanced approach that considers not just the upfront cost but also the long-term benefits and potential savings can significantly impact a business's manufacturing efficiency and product quality. Engage with knowledgeable industry professionals, rigorously assess your specific operational requirements, and make a purchase decision that aligns with your strategic goals.

Share:

Latest news

Applications of High-Speed Thread Rolling in Automotive

NewsMay.22,2025

Steel Bar Thread Rolling Machine Customization Options

NewsMay.22,2025

Vertical Thread Rolling Machines

NewsMay.22,2025

CNC Thread Rolling Machine Automation Advantages

NewsMay.22,2025

Market Demand Trends of Small Thread Rolling Machines

NewsMay.22,2025

Types of Thread Rolling Machines and Their Industrial Applications

NewsMay.22,2025