-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Th6 . 14, 2024 00:00

Back to list

Automatic thread rolling machine manufacturer

The Pivotal Role of Automatic Thread Rolling Machines in Modern Factory Operations

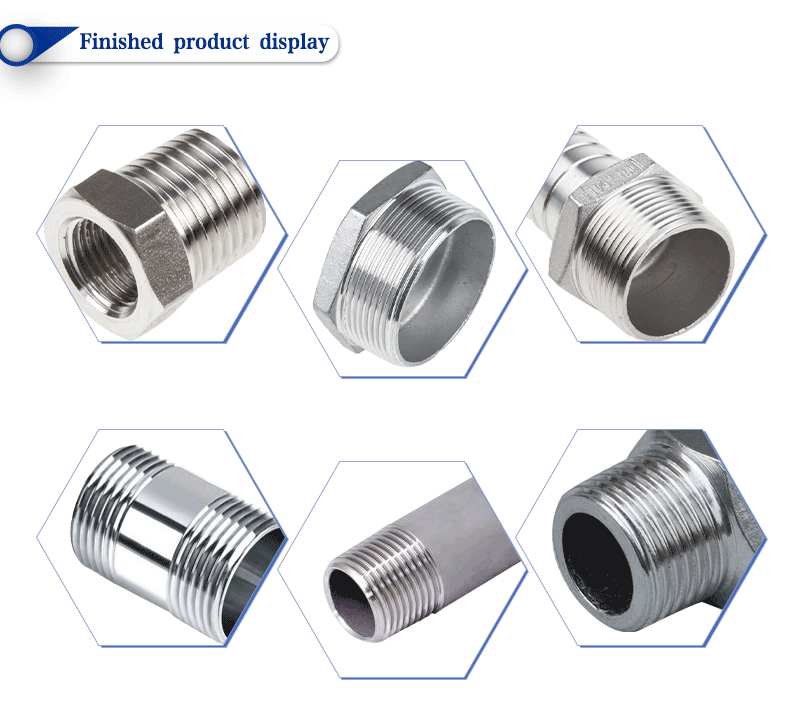

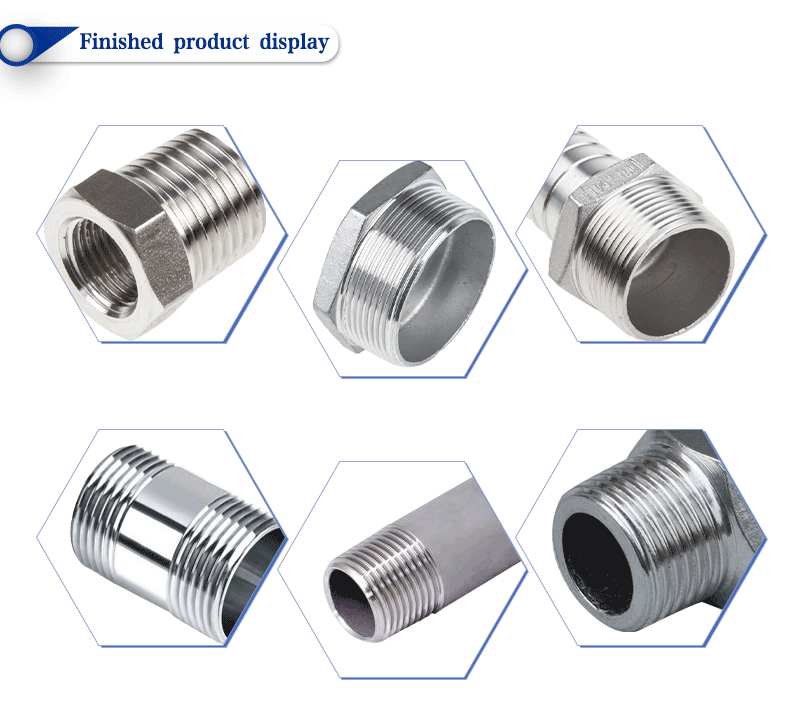

In the realm of industrial manufacturing, the Automatic Thread Rolling Machine Factory stands as a beacon of precision and efficiency. This specialized facility is dedicated to the production of high-quality thread rolling machines that revolutionize the way threads are formed on various materials, predominantly metals.

Thread rolling is an essential process in engineering, particularly in the production of screws, bolts, and other fasteners. It involves shaping a thread by pressing a pre-formed die against the material's surface, creating a stronger, more precise thread than conventional cutting methods. The automatic thread rolling machine takes this process to new heights with its advanced technology and automation capabilities.

At the heart of these factories lies a commitment to innovation and technological advancement. The machines they produce are designed to perform complex threading operations with exceptional speed and accuracy. With computerized controls and sophisticated software, these machines can handle a wide range of diameters and thread pitches, making them versatile tools for diverse industries.

The automatic nature of these machines significantly reduces human intervention, minimizing errors and enhancing productivity. They are equipped with features like automatic feed systems, self-detecting fault mechanisms, and real-time monitoring, ensuring consistent quality and minimal downtime. Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks

Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks automatic thread rolling machine factory.

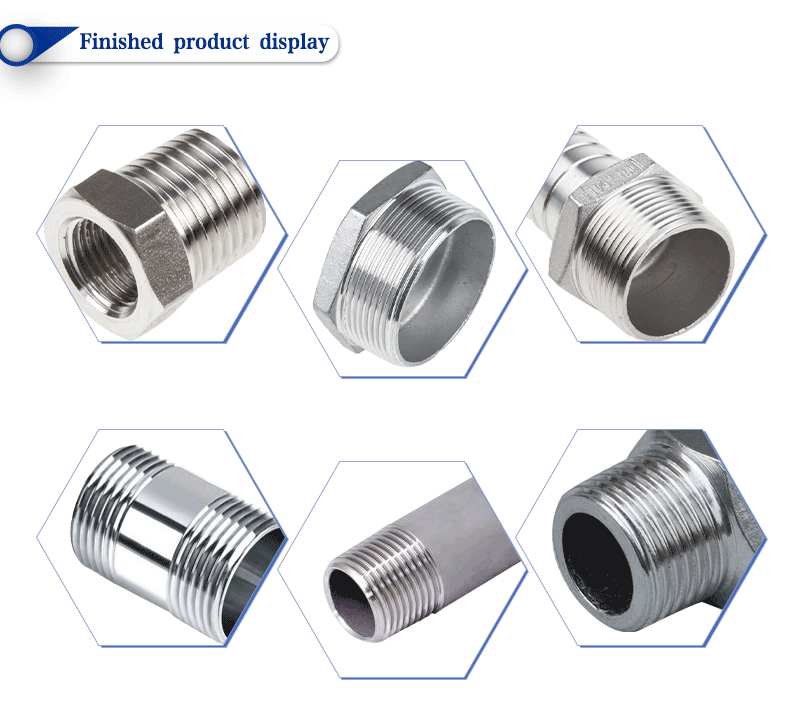

Beyond the factory floor, the impact of automatic thread rolling machines extends to the overall manufacturing landscape. By streamlining production processes and improving product consistency, they contribute to increased efficiency and cost savings for businesses. Furthermore, the durability and resilience of threads produced by these machines result in longer-lasting components, benefiting end-users and fostering a culture of sustainability.

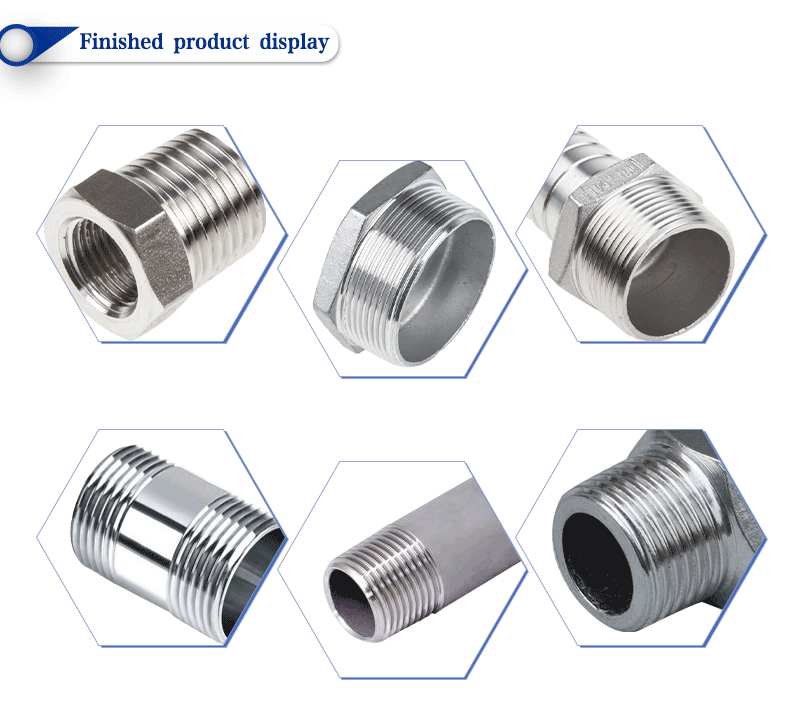

In today's global market, where competition is fierce and customer demands are ever-evolving, the Automatic Thread Rolling Machine Factory plays a crucial role. They not only manufacture cutting-edge machinery but also provide technical support and customization services, catering to the unique requirements of each client.

In conclusion, the Automatic Thread Rolling Machine Factory is a testament to the power of engineering and automation in modern manufacturing. By continuously pushing the boundaries of technology, these facilities are reshaping the way we approach threading processes, ultimately driving progress in the industrial world. Their contribution to increased productivity, improved product quality, and workplace safety cannot be overstated, making them an indispensable part of the global manufacturing ecosystem.

automatic thread rolling machine factory.

Beyond the factory floor, the impact of automatic thread rolling machines extends to the overall manufacturing landscape. By streamlining production processes and improving product consistency, they contribute to increased efficiency and cost savings for businesses. Furthermore, the durability and resilience of threads produced by these machines result in longer-lasting components, benefiting end-users and fostering a culture of sustainability.

In today's global market, where competition is fierce and customer demands are ever-evolving, the Automatic Thread Rolling Machine Factory plays a crucial role. They not only manufacture cutting-edge machinery but also provide technical support and customization services, catering to the unique requirements of each client.

In conclusion, the Automatic Thread Rolling Machine Factory is a testament to the power of engineering and automation in modern manufacturing. By continuously pushing the boundaries of technology, these facilities are reshaping the way we approach threading processes, ultimately driving progress in the industrial world. Their contribution to increased productivity, improved product quality, and workplace safety cannot be overstated, making them an indispensable part of the global manufacturing ecosystem.

Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks

Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks Moreover, the reduced need for manual labor contributes to a safer work environment, as operators are shielded from repetitive strain injuries and hazardous tasks automatic thread rolling machine factory.

Beyond the factory floor, the impact of automatic thread rolling machines extends to the overall manufacturing landscape. By streamlining production processes and improving product consistency, they contribute to increased efficiency and cost savings for businesses. Furthermore, the durability and resilience of threads produced by these machines result in longer-lasting components, benefiting end-users and fostering a culture of sustainability.

In today's global market, where competition is fierce and customer demands are ever-evolving, the Automatic Thread Rolling Machine Factory plays a crucial role. They not only manufacture cutting-edge machinery but also provide technical support and customization services, catering to the unique requirements of each client.

In conclusion, the Automatic Thread Rolling Machine Factory is a testament to the power of engineering and automation in modern manufacturing. By continuously pushing the boundaries of technology, these facilities are reshaping the way we approach threading processes, ultimately driving progress in the industrial world. Their contribution to increased productivity, improved product quality, and workplace safety cannot be overstated, making them an indispensable part of the global manufacturing ecosystem.

automatic thread rolling machine factory.

Beyond the factory floor, the impact of automatic thread rolling machines extends to the overall manufacturing landscape. By streamlining production processes and improving product consistency, they contribute to increased efficiency and cost savings for businesses. Furthermore, the durability and resilience of threads produced by these machines result in longer-lasting components, benefiting end-users and fostering a culture of sustainability.

In today's global market, where competition is fierce and customer demands are ever-evolving, the Automatic Thread Rolling Machine Factory plays a crucial role. They not only manufacture cutting-edge machinery but also provide technical support and customization services, catering to the unique requirements of each client.

In conclusion, the Automatic Thread Rolling Machine Factory is a testament to the power of engineering and automation in modern manufacturing. By continuously pushing the boundaries of technology, these facilities are reshaping the way we approach threading processes, ultimately driving progress in the industrial world. Their contribution to increased productivity, improved product quality, and workplace safety cannot be overstated, making them an indispensable part of the global manufacturing ecosystem. Share:

Latest news

Thread Rolling Tool Selection Guide

NewsJul.29,2025

Thread Rolling Machine Working Principle and Applications

NewsJul.29,2025

Rebar Thread Rolling Machine for Construction Sites

NewsJul.29,2025

Precision Control in Bolt Thread Rolling Machines

NewsJul.29,2025

Nail Thread Rolling Machine Safety Features

NewsJul.29,2025

Flat Thread Rolling Machine Thread Profile

NewsJul.29,2025