-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

IsiNgisi

IsiNgisi -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

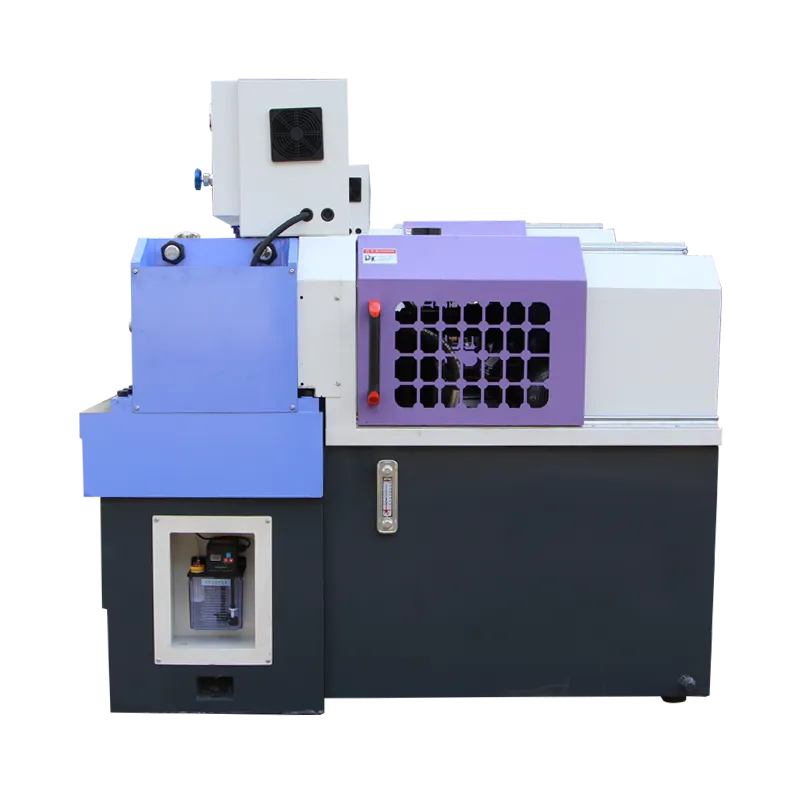

Hydraulic Thread Rolling Machine Manufacturers

In today’s fast-paced manufacturing industry, hydraulic thread rolling machine manufacturers play a pivotal role in shaping how precision threading is done across sectors. These manufacturers offer powerful solutions tailored to produce high-strength threads through the cold-forming process, which maintains the structural integrity of components and enhances their durability.

Leading hydraulic thread rolling machine manufacturers provide models equipped with user-friendly controls, automated feeding systems, hydraulic clamping mechanisms, and adjustable speed settings. The machines operate quietly and require less maintenance compared to mechanical alternatives, making them a preferred choice for medium to large production batches.

Whether it’s automotive fasteners, aerospace components, or industrial bolts, these manufacturers understand the need for reliable threading machines that can consistently perform. They also offer after-sales service, spare parts support, and customized machine builds based on specific threading applications.

Understanding Thread Rolling Machine Price in the Modern Market

The thread rolling machine price varies greatly depending on machine size, features, automation level, brand, and intended industrial use. Entry-level manual models may cost as low as a few thousand dollars, while high-capacity, fully automated hydraulic or CNC-controlled systems can range into tens of thousands.

When evaluating thread rolling machine price, buyers must also consider the value-added features such as die compatibility, production speed, control interface, and build quality. A slightly higher investment in a premium machine can result in better long-term ROI due to reduced downtime, longer tool life, and higher production accuracy.

Professional hydraulic thread rolling machine manufacturers often provide flexible pricing plans for businesses needing to scale operations. Some even offer leasing or financing programs to make it easier for manufacturers to access high-performance equipment without upfront capital strain.

Ultimately, pricing reflects not just machine functionality, but also the manufacturer’s service reputation, availability of replacement parts, and overall durability of the product.

Exploring the Various Types of Thread Rolling Techniques

The types of thread rolling used across industries are diverse, each serving specific production needs and material characteristics. Understanding these types is crucial for selecting the right machine and process.

Flat die thread rolling is the most common method for producing fasteners like screws, bolts, and studs. It uses two flat dies—one stationary and one moving—to press threads onto the workpiece in a quick, linear motion. This is best for high-speed production of small components.

Radial thread rolling, often performed using hydraulic thread rolling machines, uses two or three round dies that rotate and squeeze the workpiece. It’s ideal for forming long or thick threads and works exceptionally well with tough metals.

Planetary thread rolling is another type, used for producing threaded sections on long bars. It involves a rotating die head with multiple dies that orbit around the stationary workpiece. This method is efficient for large production volumes where precision and speed are both required.

Understanding the types of thread rolling helps manufacturers optimize production and material usage while improving the quality of the final product.

How Hydraulic Thread Rolling Machine Manufacturers Ensure High Production Standards

One of the biggest advantages offered by hydraulic thread rolling machine manufacturers is their ability to maintain consistency in high-volume threading applications. Their machines are designed to deliver repeatable results, with each pass producing precise threads that meet strict dimensional and structural standards.

Most manufacturers implement advanced quality assurance protocols during production, including precision machining, rigorous calibration, and factory-level testing. They also use robust materials such as forged steel frames and hardened components to extend machine lifespan under continuous use.

Additionally, top hydraulic thread rolling machine manufacturers invest heavily in R&D to keep up with industry demands. Many integrate smart technologies such as PLC-based automation, touch-screen interfaces, real-time diagnostics, and self-lubrication systems. These features not only improve efficiency but also reduce the need for manual adjustments, allowing operators to focus on overall productivity.

Some manufacturers also collaborate with industry partners and academic institutions to develop specialized thread rolling solutions for niche sectors such as medical devices, defense, and aerospace engineering.

Key Considerations Before Choosing a Thread Rolling Machine

When selecting a machine from one of the top hydraulic thread rolling machine manufacturers, it’s important to analyze your production needs. Start by identifying the types of materials you will be working with, the required thread specifications, and the volume of production.

A good understanding of types of thread rolling will help match your application with the appropriate machine. For example, radial thread rolling is perfect for short to medium-length components, while flat die rolling is better for standard fasteners.

Price is also a critical factor. Comparing thread rolling machine price across different brands and capabilities will help you find a solution that fits your budget without compromising on quality. Consider the machine’s energy efficiency, ease of operation, support services, and available upgrades.

It’s also advisable to request machine demonstrations or sample runs before committing. Many reputable manufacturers offer this service to showcase the real-world performance of their equipment. After-sales support, including operator training, spare parts supply, and maintenance plans, should also be part of the decision-making process.

By considering these elements, manufacturers can invest in machines that not only meet current production needs but also scale with future business growth.

Types of thread rolling FAQs

What are the benefits of buying from hydraulic thread rolling machine manufacturers?

Purchasing from reputable hydraulic thread rolling machine manufacturers ensures that you receive a well-built, durable machine designed for high-precision threading. These manufacturers offer advanced features like automatic feeding, programmable control systems, and long-term maintenance support, helping you streamline operations and reduce error rates.

How does thread rolling compare to thread cutting in terms of price and performance?

Though the thread rolling machine price might be higher upfront than a thread-cutting machine, the performance benefits are substantial. Thread rolling strengthens the material, produces no chip waste, and significantly extends tool life. Over time, lower operational costs and higher production efficiency justify the initial investment.

Which types of thread rolling are best for industrial bolts and screws?

For industrial bolts and screws, flat die thread rolling is the most efficient due to its high speed and consistent output. Radial thread rolling is also used when dealing with larger diameters or special materials. Understanding types of thread rolling ensures that manufacturers choose the best method for their application.

Can a hydraulic thread rolling machine handle various thread sizes and materials?

Yes, most machines offered by hydraulic thread rolling machine manufacturers can handle a wide range of thread sizes, pitches, and materials. By switching dies and adjusting settings, the same machine can produce threads on steel, aluminum, titanium, and other alloys without compromising thread quality.

What should I check before buying a thread rolling machine?

Before purchasing, compare thread rolling machine price, production speed, machine size, and compatibility with your existing processes. Request a demo or test run if possible. Also, assess the manufacturer’s reputation, warranty terms, and support services to ensure long-term value and performance.

Hydraulic Thread Rolling Machine Manufacturers | Superior Quality & Precision

Hydraulic Thread Rolling Machine Manufacturers A Comprehensive Overview

In the modern industrial landscape, hydraulic thread rolling machines have become essential tools for manufacturers engaged in producing high-quality threaded components. These machines utilize hydraulic pressure to create threads on various metal substrates, ensuring precision, consistency, and efficiency in production. As the demand for threaded parts grows across different industries, the role of hydraulic thread rolling machine manufacturers has become increasingly significant.

What is a Hydraulic Thread Rolling Machine?

Hydraulic thread rolling machines operate on a principle that transforms flat metal into cylindrical shapes with threads. The process is achieved through the application of intense pressure, which not only molds the material but also improves its grain structure, resulting in enhanced tensile strength. This method is often preferred over traditional cutting techniques because it produces less waste and allows for rapid production rates.

Key Features and Benefits

Manufacturers of hydraulic thread rolling machines focus on incorporating advanced features to meet the diverse needs of their clientele. Key characteristics include

1. Hydraulic Power These machines utilize hydraulic systems that provide consistent pressure and can accommodate various types of materials, including steel, aluminum, and alloys. 2. Versatility Hydraulic thread rolling machines can be designed to produce different types of threads, whether fine or coarse, right or left-handed, making them suitable for a broad range of applications.

3. Efficiency The process is known for reducing cycle times significantly compared to traditional machining methods. Manufacturers benefit from lower operational costs and higher throughput.

4. Precision With the ability to maintain tight tolerances, these machines produce high-quality threads that reduce the risk of failure in the end application.

hydraulic thread rolling machine manufacturers

Choosing a Manufacturer

When selecting a hydraulic thread rolling machine manufacturer, several factors should be considered

- Experience and Reputation Established manufacturers with a track record of quality and reliability are often preferable. Researching customer reviews and case studies can provide valuable insights.

- Customization Options Since different industries may require specific thread profiles or machine configurations, a manufacturer that offers customization can better meet unique production needs.

- Post-Sale Support Reliable customer service, including maintenance and spare parts availability, is crucial for ongoing operations and minimizing downtime.

- Technology and Innovation Manufacturers that invest in advanced technologies and continuous improvement can provide more efficient and capable machines.

Conclusion

Hydraulic thread rolling machines are indispensable in manufacturing threaded components for various applications. The role of manufacturers in producing these machines cannot be understated, as they ensure the availability of reliable, efficient, and versatile solutions for the industry's needs. By considering key features and making informed decisions when selecting a manufacturer, companies can enhance their production processes and contribute to their overall success.