-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

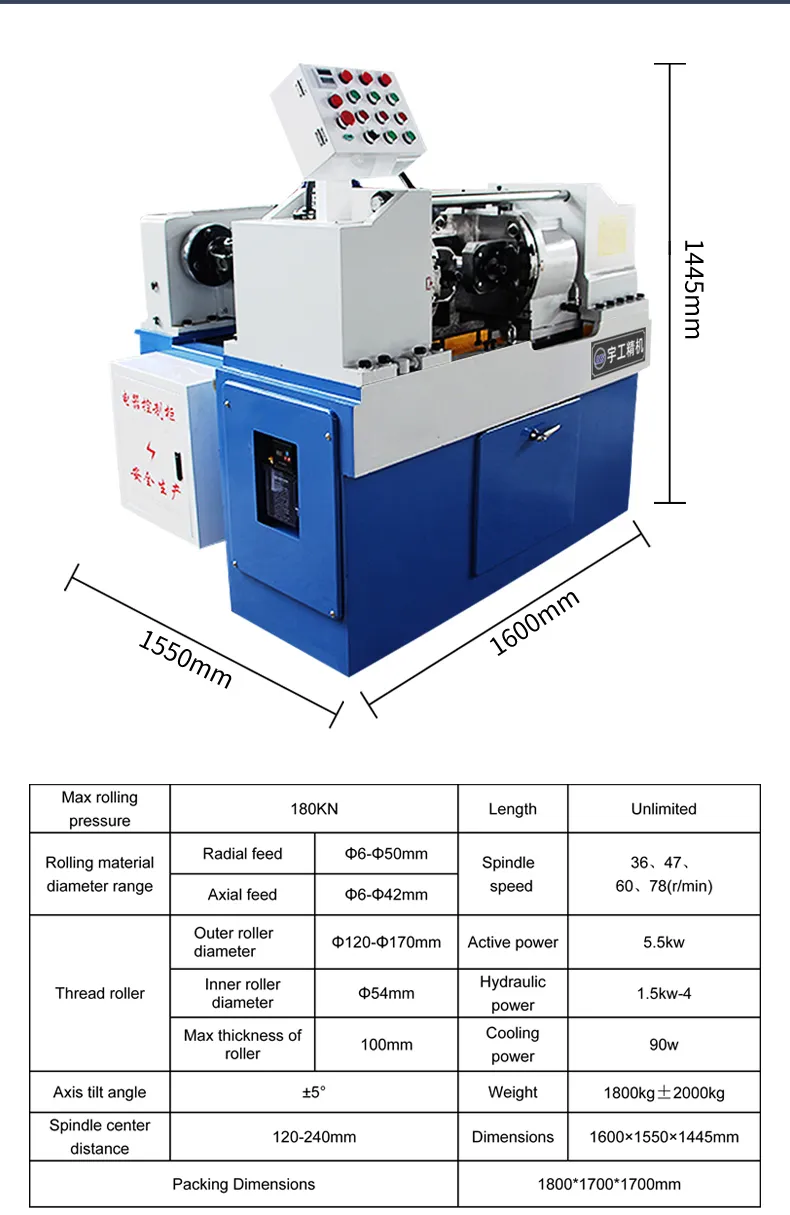

Bolt Rolling Machine Operation Manual

Operating a bolt rolling machine with precision and efficiency is crucial for the production of high-quality threaded fasteners. Bolt thread rolling machines and steel thread rolling machines are essential tools in the manufacturing industry, providing a reliable and consistent method for creating threads. This operation manual will guide you through the process of using these machines, ensuring optimal performance and longevity of the equipment. Hebei Moto Machinery Trade Co., Ltd., with its extensive experience in machinery manufacturing, offers top-tier machines that are recognized for their outstanding design and competitive pricing.

-

Overview of Bolt Rolling Machines

- Bolt rolling machines are designed to roll a workpiece through a series of rollers to form threads without cutting.

- These machines are vital in industries where threaded fasteners are a critical component.

-

Components of a Steel Thread Rolling Machine

- Steel thread rolling machinesconsist of main and cross rollers, feed mechanisms, and control systems for speed regulation.

- The rollers are precisely shaped to match the thread profile they are intended to produce.

-

Operation Steps for Bolt Thread Rolling Machine

- Ensure the machine is properly set up with all safety guards in place. • Load the workpiece into the machine, aligning it with the rollers.

- Start the machine and adjust the rollers to the desired thread specifications.

- Maintenance and Safety

- Regular maintenance, including lubrication and inspection of rollers, is essential for the longevity of the machine.

- Always follow safety protocols, including wearing protective gear and ensuring the machine is turned off before making adjustments.

Bolt Rolling Machine FAQS

Q: How does a bolt rolling machine enhance bolt strength compared to cutting methods?

A: A bolt rolling machine forms threads via cold working, which compresses the metal rather than removing it. This process aligns the material’s grain structure, increasing tensile strength and fatigue resistance by up to 30% compared to cut threads. The absence of cutting-induced micro-cracks also makes rolled bolts more durable in high-vibration applications, such as automotive engines or heavy machinery. Additionally, the smooth surface finish of rolled threads reduces stress concentrations, further enhancing the bolt’s lifespan.

Q: What materials are best suited for a bolt thread rolling machine?

A: A bolt thread rolling machine performs optimally with ductile materials that can deform without cracking. Carbon steel (e.g., SAE 1018) and alloy steel (e.g., 4140) are common choices for industrial bolts, while stainless steel (e.g., 304, 316) is preferred for corrosion resistance. Non-ferrous metals like brass or aluminum are suitable for decorative or lightweight bolts, though lower rolling pressures are needed to prevent material distortion. Hardened steels (over HRC 40) may require pre-heat treatment to maintain die longevity.

Q: How does a steel thread rolling machine handle large-diameter bolts?

A: A steel thread rolling machine designed for large diameters typically uses hydraulic or servo-driven systems to generate higher rolling forces. These machines feature robust dies and reinforced frames to withstand the stress of deforming thick steel. For bolts exceeding M30, multi-stage rolling processes may be employed to gradually shape the thread, preventing material failure. Some models also include pre-rolling alignment systems to ensure concentricity, the key to producing high-precision threads on large components for construction or infrastructure projects.

Q: Can a bolt rolling machine be integrated into an automated production line?

A: Yes, modern bolt rolling machines often feature PLC controls and robotic interfaces for seamless automation. Automated feeding systems can sort and position bolts before rolling, while post-rolling inspection stations check thread dimensions using laser scanners. Integration with ERP systems allows real-time production data tracking, reducing manual intervention and improving throughput. This setup is ideal for mass-producing bolts for automotive OEMs or fastener distributors requiring consistent, high-volume output.

Q: What maintenance practices prolong the life of a steel thread rolling machine?

A: To maintain a steel thread rolling machine, regularly inspect dies for wear (replace at the first sign of chipping), clean metal debris from the rolling area, and lubricate moving parts with heat-resistant grease. Hydraulic systems should have fluid tested annually for contamination, while electrical components need checks for loose connections. Calibrating the machine’s pressure and speed sensors quarterly ensures thread consistency. Following these steps can extend die life by 50% and reduce unexpected downtime in high-volume manufacturing environments.

Welcome to Hebei Moto Machinery – Where Precision Meets Performance!

Nestled in Xingwan Town, Ren County of Xingtai City, Hebei Province – a cradle of China’s machinery manufacturing heritage – Hebei Moto Machinery Trade Co., Ltd. stands as a testament to two decades of engineering excellence. Specializing in thread rolling machines and diameter reducing machines, we blend time-honored craftsmanship with cutting-edge innovation to deliver solutions that redefine industry standards.

Our ISO 9001-certified production ensures every machine meets global quality benchmarks, from the robust design of our thread rollers – ideal for automotive fasteners and construction rebar – to the precision-engineered diameter reducers that transform metal with minimal waste. What sets us apart? A commitment to competitive pricing without compromising on durability, supported by a team of seasoned engineers who tailor solutions to your unique needs.

Trusted by clients across Southeast Asia, the Middle East, Europe, and Africa, our machines power everything from high-volume manufacturing lines to specialized projects. Whether you seek efficiency gains, cost savings, or technical superiority, our professional service team guides you from selection to after-sales support.

Discover how Hebei Moto Machinery can elevate your operations. Visit www.motetools.com today and join thousands of satisfied customers who trust us to roll out success, one precision component at a time.