-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

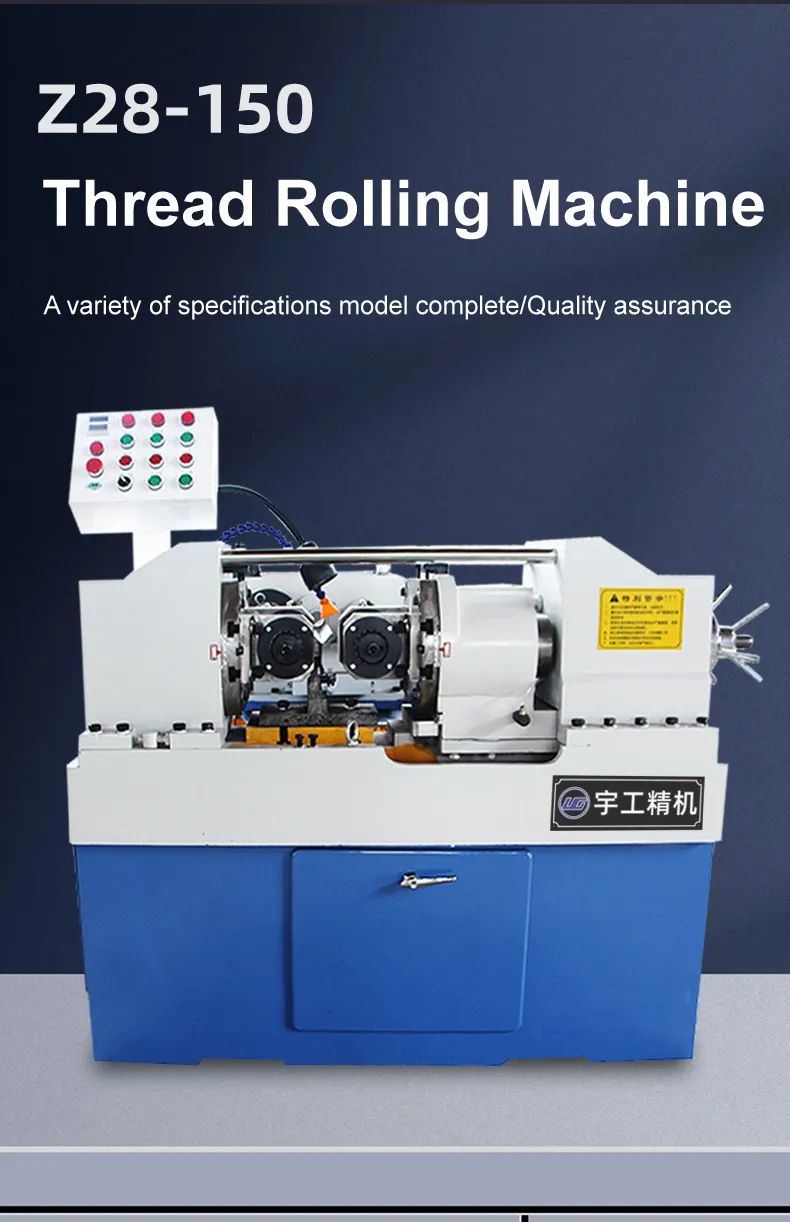

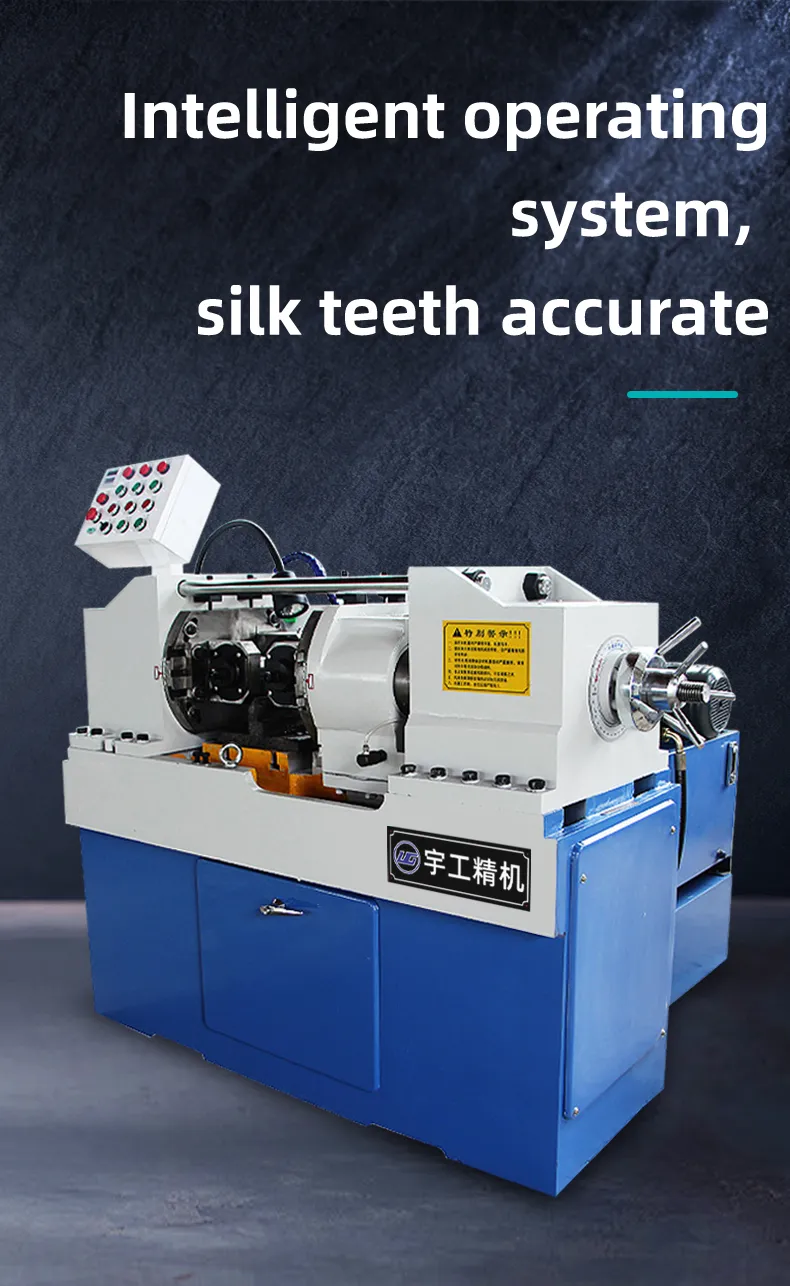

Thread Rolling Equipment: Maintenance and Servicing Tips

The efficiency and longevity of thread rolling equipment, including thread rolling machine flat die and vertical thread rolling machine, are heavily dependent on regular maintenance and servicing. Proper care and attention to these machines can significantly extend their operational life and ensure consistent performance. Hebei Moto Machinery Trade Co., Ltd., with its extensive experience in machinery manufacturing, offers a range of high-quality thread rolling equipment that meets international standards.

-

Importance of Regular Maintenance for Thread Rolling Equipment

- Regular maintenance is crucial for the optimal performance of thread rolling equipment.

- It helps prevent costly breakdowns and ensures the production process remains uninterrupted.

-

Servicing Tips for Thread Rolling Machine Flat Die

- Conduct routine checks of the flat die for any signs of wear or damage.

- Lubricate moving parts to reduce friction and extend the life of the machine.

-

Vertical Thread Rolling Machine Servicing

- Ensure the vertical machine is cleaned after each use to prevent debris buildup.

- Regularly inspect the threading accuracy and make adjustments as needed.

- Benefits of Proper Servicing

- Proper servicing can enhance the threading quality and consistency.

- It can also improve the safety of the operation by identifying potential hazards.

Thread Rolling Equipment FAQs

Q: What are the key differences between thread rolling equipment and traditional threading methods?

A: Thread rolling equipment forms threads through a cold working process by pressing dies against the workpiece, deforming the material to create the thread profile, rather than removing material like traditional cutting methods such as tapping or threading with a lathe. This results in threads with improved strength and fatigue resistance, as the grain flow of the metal is not disrupted. Additionally, thread rolling is generally faster, produces less waste, and can achieve higher precision and better surface finish compared to many traditional threading techniques.

Q: How does a thread rolling machine flat die affect the quality of the rolled threads?

A: The thread rolling machine flat die plays a crucial role in thread quality. The precision of the die's thread profile directly determines the accuracy of the rolled threads. High - quality flat dies with sharp, well - defined threads ensure consistent thread pitch, diameter, and flank angle. The material and hardness of the die also matter; harder materials resist wear, maintaining thread quality over a larger number of production cycles. Moreover, proper alignment and adjustment of the flat die on the machine are essential to avoid defects like thread distortion or uneven thread formation.

Q: In which industries are vertical thread rolling machines most commonly used?

A: Vertical thread rolling machines are widely utilized in multiple industries. In the automotive sector, they are used to produce bolts, studs, and axles with high - strength threads required for vehicle assembly. The aerospace industry relies on these machines for manufacturing critical components, where the fatigue resistance and precision of rolled threads are vital for safety. In the electronics industry, vertical thread rolling machines create small, precise threaded parts for connectors and fasteners. Additionally, they are common in the medical device industry for producing implants and surgical instruments that demand high - quality, biocompatible threaded components.

Q: What maintenance procedures should be followed for thread rolling equipment to ensure its longevity?

A: Regular maintenance of thread rolling equipment is essential. First, keep the machine clean, removing metal chips, debris, and lubricant residues that can interfere with operation or cause wear. Lubricate all moving parts, such as guides, slides, and bearings, according to the manufacturer's recommendations to reduce friction and prevent premature wear. Inspect the thread rolling machine flat die regularly for signs of wear, damage, or deformation; replace dies promptly to maintain thread quality. Also, check and calibrate the machine's alignment and settings periodically, and ensure that the control systems and safety features are functioning properly.

Q: Can vertical thread rolling machines be customized for specific threading requirements?

A: Yes, vertical thread rolling machines can be customized. Manufacturers can adjust the machine's capacity, such as the maximum diameter and length of the workpieces it can handle. The threading speed, force, and number of rolling cycles can also be tailored to meet specific material and thread specifications. Additionally, custom thread rolling machine flat dies can be designed to produce unique thread profiles, pitches, or special features. Automation and control systems can be customized to integrate with existing production lines, add advanced monitoring capabilities, or enable remote operation, making the vertical thread rolling machine suitable for a wide range of specialized threading needs.

|

Technical Specifications of Z28-150 Thread Rolling Machine |

|

|

Diameter Processing Range |

6-42 mm |

|

Pitch Range |

1-5 mm |

|

Main Motor Power |

5.5 KW |

|

Hydraulic Motor Power |

1.5 KW |

|

Cooling Power |

90 W |

|

Overall Dimensions (L×W×H) |

1600×1550×1445 mm |

|

Machine Weight |

1800 KG |

Welcome to Hebei Moto Machinery Trade Co., Ltd. www.motetools.com

Established in Xingwan Town, Ren County of Xingtai City, Hebei Province—a cradle of China’s machinery manufacturing heritage—Hebei Moto Machinery Trade Co., Ltd. has been shaping industrial solutions for over two decades. Specializing in thread rolling machines and diameter reducing machines, our expertise is rooted in years of innovation, allowing us to craft equipment that marries precision design with competitive pricing.

Our commitment to excellence is underscored by ISO 9001 International Quality Control System certification, ensuring every product meets global standards. From Southeast Asia to the Middle East, Europe, and Africa, our machinery powers industries worldwide, winning trust through reliability and performance. Backed by collaborations with renowned manufacturers, we deliver not just equipment, but comprehensive solutions—from technical support to after-sales service—that empower clients to thrive in their markets.

Whether you seek to optimize production efficiency or expand your product line, our team of professionals is dedicated to understanding your needs. Join countless satisfied customers who have chosen us as their trusted partner. Let’s transform your industrial aspirations into reality—together.