-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

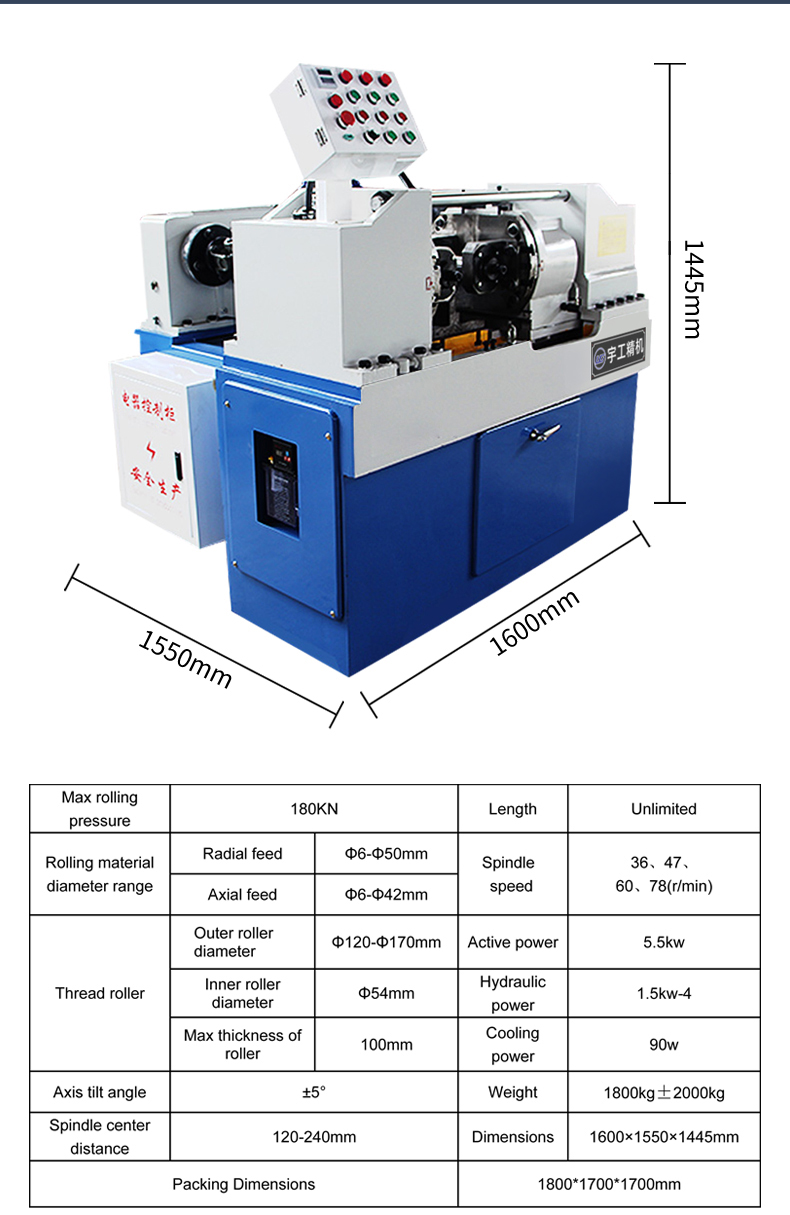

Innovative Roller Threading Machines for Enhanced Efficiency and Precision in Manufacturing

The Marvel of Roller Threading Machines Revolutionizing Manufacturing

In the fast-paced world of manufacturing, efficiency and precision are paramount. Among the myriad of innovations that have transformed production processes, roller threading machines have emerged as a significant player. These machines are designed for creating threads on various materials, providing solutions that are critical for various industries, including automotive, aerospace, and construction.

What is a Roller Threading Machine?

A roller threading machine is a specialized type of machine used to create threads on cylindrical surfaces. Unlike traditional cutting methods, which remove material to form threads, roller threading is a cold forming process that reshapes the material. The machine typically consists of hardened steel rollers that apply immense pressure to displace the material, resulting in uniform threads without creating waste.

The core advantage of roller threading machines lies in their ability to produce high-quality threads with remarkable accuracy. These machines are engineered to handle different materials, from soft metals like aluminum to harder alloys like stainless steel, making them versatile for various applications.

Historical Context and Evolution

The concept of threading has been around since ancient civilizations, but mechanical advancements have propelled it into modern manufacturing. Before the advent of roller threading machines, thread creation relied heavily on cutting tools and lathes. These methods, while effective, often resulted in excess material waste and variable thread quality.

The introduction of roller threading machines in the 20th century marked a shift in manufacturing paradigms. As industries grew and the demand for high-volume production increased, manufacturers sought efficient methods to streamline threading processes. Roller machines offered a solution that not only improved production rates but also enhanced the consistency of threaded components.

Advantages Over Traditional Methods

famous roller threading machine

1. Material Efficiency One of the most significant benefits of roller threading machines is material efficiency. Since these machines do not cut away material but rather deform it, there is minimal waste generated during the threading process.

2. Strength The process of cold forming helps to improve the mechanical properties of the thread. The deformation from roller threading can enhance the tensile strength of the material, making it more resilient in applications where high stress is anticipated.

3. Speed Roller threading machines are designed for high-speed production. They can produce multiple threads in a fraction of the time it would take for traditional methods, which is crucial for industries requiring large volumes of threaded components.

4. Quality Control The consistency and precision achieved through roller threading make it easier for manufacturers to maintain quality control standards. This is especially important in industries where even slight variations can lead to significant failures.

Modern Applications

Today, roller threading machines are an integral part of many manufacturing lines. They are commonly used in the automotive industry for producing bolts, nuts, and other fasteners critical to assembly processes. The aerospace sector also employs these machines for creating high-strength components that must endure extreme conditions.

Moreover, with the advent of smart manufacturing and Industry 4.0, roller threading machines are being integrated with advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). This integration enables real-time monitoring and data analysis, further enhancing efficiency and reducing downtime.

Conclusion

The roller threading machine stands as a testament to innovation in manufacturing technology. Its ability to produce high-quality, durable threaded components quickly and efficiently has revolutionized industries worldwide. As manufacturing continues to evolve, the importance of such machinery will only grow, proving that the fusion of engineering and technology is the backbone of modern production systems. As industries look toward the future, roller threading machines will undoubtedly play a critical role in shaping the manufacturing landscape.