-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

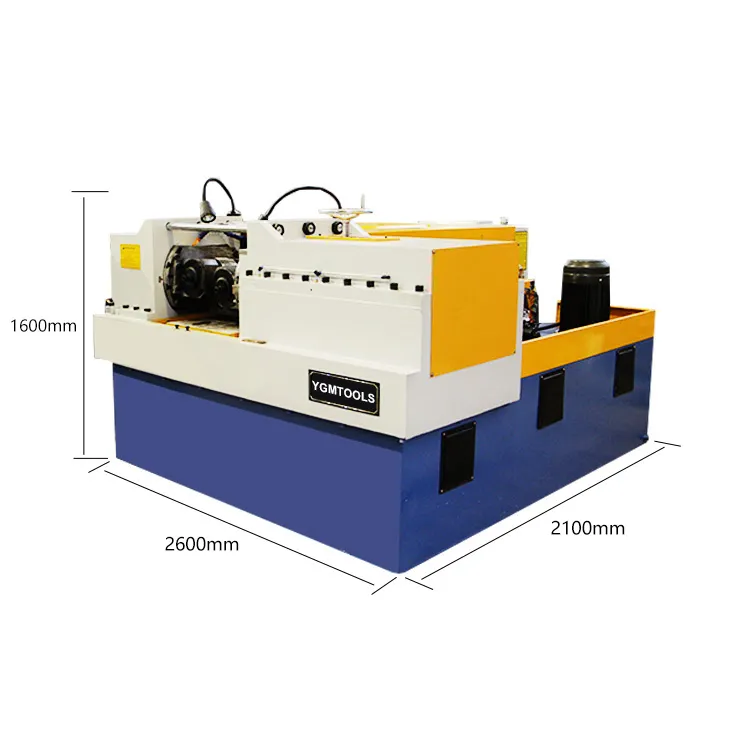

flat thread rolling machine manufacturer

Flat Thread Rolling Machine Manufacturer Revolutionizing Manufacturing Processes

In the ever-evolving landscape of manufacturing, the significance of reliable machinery cannot be overstated. Among the crucial equipment that plays a vital role in the production of fasteners and precision parts is the flat thread rolling machine. This specialized machinery has garnered attention for its efficiency and ability to produce high-quality threads with minimal waste. As businesses seek to enhance their manufacturing process, the demand for advanced flat thread rolling machine manufacturers has surged.

Flat thread rolling machines are designed to create threads on various materials using a process known as thread rolling. This method involves the deformation of the material under pressure rather than cutting, allowing for a more efficient production cycle. Not only does this reduce scrap material, but it also enhances the overall strength of the threads formed. The machines are widely used in industries ranging from automotive to construction, where precision and durability are paramount.

Choosing the right manufacturer for flat thread rolling machines is essential for any business aiming to improve its operational efficiency. A reputable manufacturer should offer advanced technology, customization options, and excellent customer service. With the rapid advancement of technology, manufacturers are incorporating features such as programmable controls and automation, making it easier for businesses to adapt to modern production requirements.

flat thread rolling machine manufacturer

One notable aspect of leading flat thread rolling machine manufacturers is their commitment to quality and innovation. These manufacturers often invest in research and development to create machines that not only meet but exceed industry standards. Utilizing high-grade materials and precision engineering ensures that the machines are durable and capable of handling various production needs. Furthermore, many manufacturers offer extensive support, including training for operators and ongoing maintenance services, which are crucial for maximizing the lifespan of the machinery.

Another vital factor is the customization offered by manufacturers. Different industries have unique requirements, and a one-size-fits-all approach does not suffice. Therefore, manufacturers that can tailor their machines to fit specific applications—such as adjusting thread profiles or accommodating particular workpiece sizes—are generally more sought after. This level of customization not only improves efficiency but also helps businesses remain competitive in a global market.

Sustainability is another growing consideration in the manufacturing sector. Modern flat thread rolling machine manufacturers are increasingly aware of their environmental impact and are implementing eco-friendly practices. From using energy-efficient components to optimizing material usage, these manufacturers are contributing to a more sustainable manufacturing future.

In conclusion, the choice of a flat thread rolling machine manufacturer significantly impacts the efficiency, quality, and sustainability of manufacturing processes. With the right equipment and support, businesses can achieve remarkable advancements in their production capabilities. As industries continue to evolve, the role of innovative manufacturers will be critical in shaping the future of manufacturing, ensuring that companies can meet the demands of a competitive market while prioritizing quality and sustainability. Investing in a reliable flat thread rolling machine and partnering with a reputable manufacturer is a strategic move toward success in today’s manufacturing landscape.