-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 26, 2024 19:59

Back to list

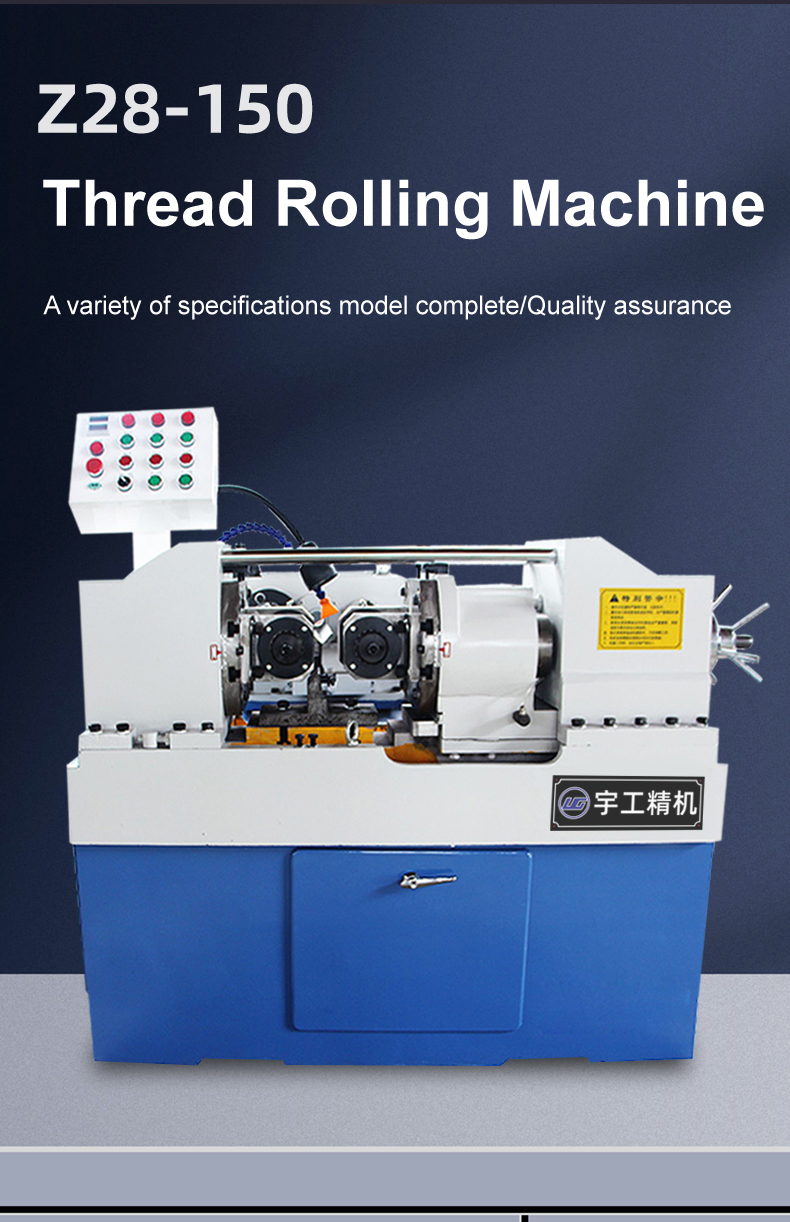

Rolling Thread Machine Maintenance and Repair Services

The Nuts and Bolts of Roll Thread Machine Services

In the realm of industrial manufacturing, the roll thread machine service plays an integral role, a critical cog in the wheel of precision engineering. This specialized service revolves around the process of creating threads on cylindrical surfaces using a roll threading machine, an innovative technology that has revolutionized the way threads are formed.

A roll thread machine, at its core, is a high-speed, high-precision tool designed to produce threads with exceptional accuracy and efficiency. It operates on the principle of cold-forming, where the thread is shaped by pressing a blank part against a set of thread rolls. This method not only ensures a consistent thread quality but also enhances the strength of the thread due to the cold-working effect.

The service offered by roll thread machine providers extends far beyond just the operation of the machinery. It encompasses a comprehensive suite of solutions, including thread design consultation, custom tooling development, thread rolling, and post-processing services. The process begins with a thorough understanding of the client's requirements, be it for aerospace components, automotive parts, or industrial machinery.

The design phase involves engineers working closely with clients to develop thread profiles that meet specific tolerances and performance criteria. Once the design is finalized, custom thread rolls are manufactured, which are the heart of the roll threading process. These rolls are precisely engineered to impart the desired thread form onto the workpiece These rolls are precisely engineered to impart the desired thread form onto the workpiece These rolls are precisely engineered to impart the desired thread form onto the workpiece These rolls are precisely engineered to impart the desired thread form onto the workpiece

These rolls are precisely engineered to impart the desired thread form onto the workpiece These rolls are precisely engineered to impart the desired thread form onto the workpiece roll thread machine service.

Thread rolling itself is a highly efficient process. The part is clamped in place and then passed through the thread rolls, which apply pressure to shape the thread. The result is a thread with superior surface finish, increased fatigue resistance, and improved dimensional stability. This service is particularly advantageous for high-volume production runs, as it can significantly reduce costs compared to cutting threads.

Post-processing services often include inspection, heat treatment, and surface finishing. This is to ensure that the final product meets the stringent standards of the industry, whether it's for durability, corrosion resistance, or aesthetic appeal.

In conclusion, roll thread machine services are more than just a mechanical operation; they are a testament to the fusion of engineering expertise, technological innovation, and a commitment to quality. They offer a streamlined solution for producing threads that are not only precise but also robust, making them indispensable in various sectors. As industries continue to evolve, the role of roll thread machine services will only become more significant, shaping the future of manufacturing with every thread they roll.

roll thread machine service.

Thread rolling itself is a highly efficient process. The part is clamped in place and then passed through the thread rolls, which apply pressure to shape the thread. The result is a thread with superior surface finish, increased fatigue resistance, and improved dimensional stability. This service is particularly advantageous for high-volume production runs, as it can significantly reduce costs compared to cutting threads.

Post-processing services often include inspection, heat treatment, and surface finishing. This is to ensure that the final product meets the stringent standards of the industry, whether it's for durability, corrosion resistance, or aesthetic appeal.

In conclusion, roll thread machine services are more than just a mechanical operation; they are a testament to the fusion of engineering expertise, technological innovation, and a commitment to quality. They offer a streamlined solution for producing threads that are not only precise but also robust, making them indispensable in various sectors. As industries continue to evolve, the role of roll thread machine services will only become more significant, shaping the future of manufacturing with every thread they roll.

These rolls are precisely engineered to impart the desired thread form onto the workpiece These rolls are precisely engineered to impart the desired thread form onto the workpiece

These rolls are precisely engineered to impart the desired thread form onto the workpiece These rolls are precisely engineered to impart the desired thread form onto the workpiece roll thread machine service.

Thread rolling itself is a highly efficient process. The part is clamped in place and then passed through the thread rolls, which apply pressure to shape the thread. The result is a thread with superior surface finish, increased fatigue resistance, and improved dimensional stability. This service is particularly advantageous for high-volume production runs, as it can significantly reduce costs compared to cutting threads.

Post-processing services often include inspection, heat treatment, and surface finishing. This is to ensure that the final product meets the stringent standards of the industry, whether it's for durability, corrosion resistance, or aesthetic appeal.

In conclusion, roll thread machine services are more than just a mechanical operation; they are a testament to the fusion of engineering expertise, technological innovation, and a commitment to quality. They offer a streamlined solution for producing threads that are not only precise but also robust, making them indispensable in various sectors. As industries continue to evolve, the role of roll thread machine services will only become more significant, shaping the future of manufacturing with every thread they roll.

roll thread machine service.

Thread rolling itself is a highly efficient process. The part is clamped in place and then passed through the thread rolls, which apply pressure to shape the thread. The result is a thread with superior surface finish, increased fatigue resistance, and improved dimensional stability. This service is particularly advantageous for high-volume production runs, as it can significantly reduce costs compared to cutting threads.

Post-processing services often include inspection, heat treatment, and surface finishing. This is to ensure that the final product meets the stringent standards of the industry, whether it's for durability, corrosion resistance, or aesthetic appeal.

In conclusion, roll thread machine services are more than just a mechanical operation; they are a testament to the fusion of engineering expertise, technological innovation, and a commitment to quality. They offer a streamlined solution for producing threads that are not only precise but also robust, making them indispensable in various sectors. As industries continue to evolve, the role of roll thread machine services will only become more significant, shaping the future of manufacturing with every thread they roll. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025