-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling equipment factory

Innovations in Thread Rolling Equipment Manufacturing

In the world of industrial manufacturing, the production of threaded fasteners is a crucial process that directly impacts various sectors, from automotive to aerospace. Thread rolling equipment has emerged as a pivotal technology in this field, enabling manufacturers to produce high-quality threads with superior mechanical properties. This article delves into the intricacies of thread rolling equipment factories, exploring their significance, technological advancements, and the future of the industry.

Understanding Thread Rolling

Thread rolling is a cold forming process that creates threads on cylindrical blanks. Unlike traditional cutting methods, which remove material, thread rolling reshapes the material, resulting in a stronger and more durable thread. This method is not only efficient but also enhances the mechanical properties of the material, making it more resistant to wear and fatigue.

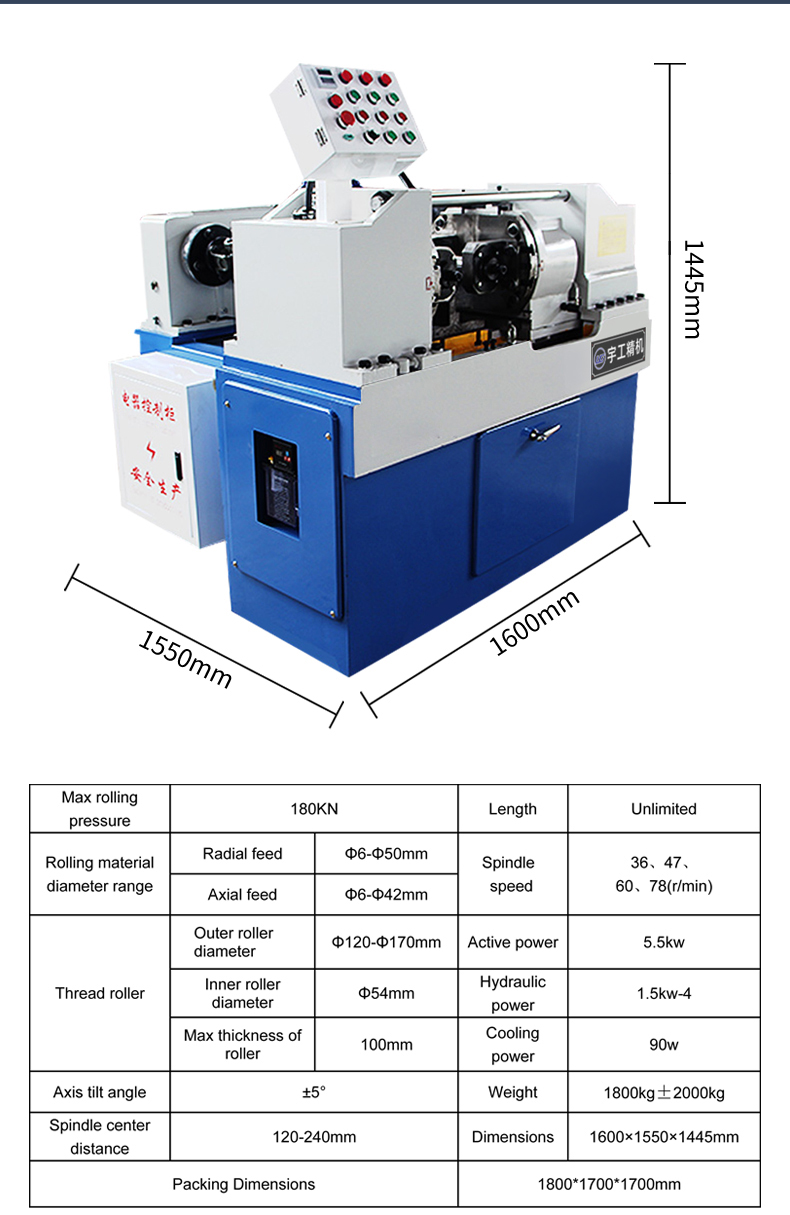

The equipment involved in thread rolling is specialized, comprising various types of machines such as flat thread rollers, cylindrical thread rollers, and multi-die thread rolling machines. Each of these machines is designed for specific applications and materials, catering to the diverse needs of manufacturers.

The Role of Thread Rolling Equipment Factories

Thread rolling equipment factories play a vital role in the manufacturing ecosystem

. They are responsible for producing, maintaining, and enhancing the machinery used in the thread rolling process. These factories focus on precision engineering to design machines that can handle different sizes and types of threaded fasteners.One of the primary benefits of thread rolling equipment factories is their ability to innovate. As industries evolve, the demand for more efficient and capable machinery increases. Manufacturers are continually in search of ways to increase production rates while minimizing costs. This has led to significant advancements in thread rolling technology, resulting in machines that are not only faster but also more energy-efficient.

Technological Advancements

thread rolling equipment factory

Recent years have seen a surge in the integration of automation and smart technologies in thread rolling equipment. Advanced computer numerical control (CNC) systems are now commonplace in thread rolling machines, allowing for precise control over the rolling process. This technology enhances the quality of the finished product and reduces the likelihood of defects.

Moreover, manufacturers are increasingly utilizing materials like high-speed steel and carbide in the construction of rolling dies. These materials ensure higher durability and longevity, significantly reducing maintenance costs and downtime. The evolution of alloys and coatings has also improved performance, allowing for greater efficiency in high-volume production environments.

Sustainability in Manufacturing

As environmental consciousness grows, thread rolling equipment factories are also adopting sustainable practices. The industry is now focusing on reducing waste and energy consumption, which aligns with global initiatives aimed at minimizing environmental impacts. Manufacturers are investing in energy-efficient machines and processes, which not only benefit the planet but also reduce operating costs.

Recycling and reusing materials are becoming more prevalent in thread rolling equipment production. By creating a closed-loop system, factories can lower their carbon footprint while maintaining high production standards. These sustainability initiatives are not just beneficial for the environment; they also enhance the reputation of manufacturers, making them more attractive partners for eco-conscious clients.

The Future of Thread Rolling Equipment Factories

Looking ahead, the future of thread rolling equipment factories is bright and promising. The increasing demand for high-performance threaded fasteners across various industries will likely drive innovation further. With the advent of Industry 4.0, factories will integrate more Internet of Things (IoT) technologies, allowing for real-time monitoring and analytics of machine performance.

As factories continue to embrace digital transformations, they will be better equipped to meet the evolving needs of the market. The ongoing development of advanced materials and technologies will provide new avenues for enhancing the efficiency and quality of thread rolling processes.

In conclusion, thread rolling equipment factories are pivotal in shaping the future of manufacturing threaded fasteners. Through innovation and a commitment to sustainability, these factories are not only boosting production efficiency but also ensuring that they remain competitive in a rapidly changing industrial landscape. The synergy between tradition and technology will undoubtedly continue to fuel advancements in the field, setting the stage for a brighter, more efficient manufacturing future.